Fertilizer rich in nitrogen and phosphorus and preparation method thereof

A fertilizer and phosphoric acid technology, applied in nitrogen fertilizer, organic fertilizer, excretion fertilizer, etc., can solve the problem of low quality of compost, and achieve the effect of increasing fertilizer efficiency, benefiting growth and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

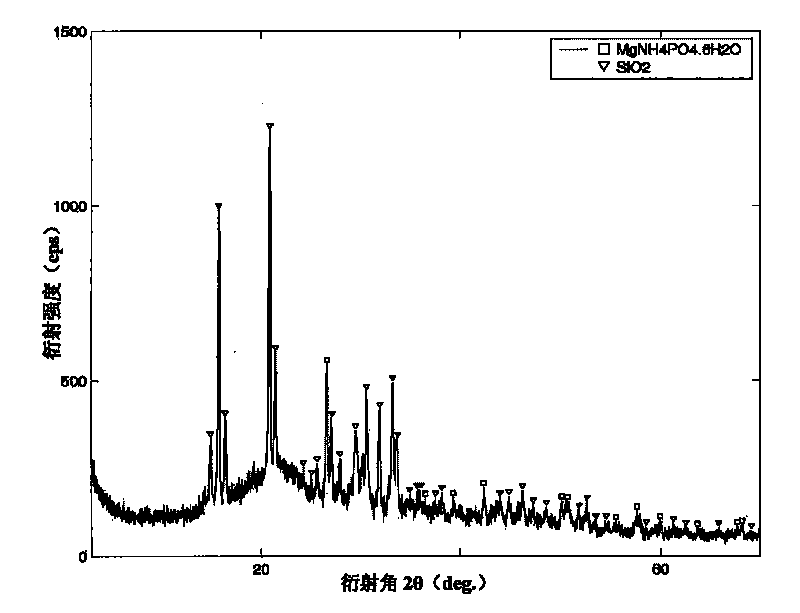

Embodiment 1

[0025] Embodiment 1, magnesium hydroxide, phosphoric acid, urea, straw, livestock and poultry excrement are 1.4: 2.4: 2.2: 41: 53 (dry weight) by mass ratio and prepare compost product

[0026] Use pig manure and corn stalks crushed to a length of 1 cm as composting materials, mix pig manure, straw, urea, magnesium hydroxide, and phosphoric acid according to the dry weight ratio of 53:41:2.2:1.4:2.4, and make the mixed material C / N ratio=15, the wet weight of the material is about 21.5kg (when the moisture content is 65%).

[0027] 110g of magnesium hydroxide was mixed with 2kg of water, and then slowly poured into 118ml of phosphoric acid to obtain a granular emulsion. Among them, Mg(OH) 2 and H 3 PO 4 The mass ratio of 1.4:2.4, Mg(OH) 2 and H 3 PO 4 The mass accounts for 3.8% of the total dry matter weight of the material.

[0028] Mix and stir the compost material to adjust the moisture, add the above emulsion, and make the emulsion particles evenly adhere to the su...

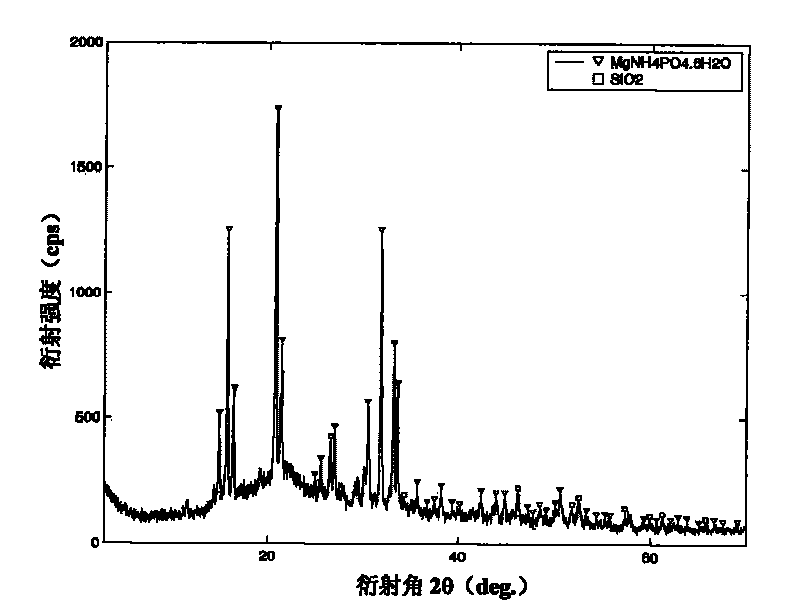

Embodiment 2

[0040] Embodiment 2, magnesium hydroxide, phosphoric acid, urea, straw, livestock and poultry excrement are 1.7: 5.6: 2.1: 39.6: 51 (dry weight) preparation compost product by mass ratio

[0041]Pig manure, straw, urea, magnesium hydroxide, phosphoric acid are mixed according to the dry weight ratio of 51: 40: 2.1: 1.7: 5.6, so that the mixed material C / N ratio=15, and the total weight of the material is 21.8kg (when the moisture content is 65% of the time).

[0042] 133g of magnesium hydroxide was mixed with 2kg of water, and then slowly poured into 286ml of phosphoric acid to obtain a granular emulsion. Among them, Mg(OH) 2 and H 3 PO 4 The mass ratio of 1.7:5.6, Mg(OH) 2 and H 3 PO 4 The mass accounts for 7.3% of the total dry matter weight of the material.

[0043] Through proper stirring, the milky particles are evenly attached to the surface of the material, so that the ammonia in the compost and the odor caused by it can be controlled during the compost productio...

Embodiment 3

[0048] Embodiment 3, magnesium hydroxide, phosphoric acid, urea, straw, livestock and poultry excrement are 1.5: 7.4: 2.1: 39: 50 (dry weight) preparation compost product by mass ratio

[0049] Pig manure, straw, urea, magnesium hydroxide and phosphoric acid are mixed according to the dry weight ratio of 50:39:2.1:1.5:7.4, so that the C / N ratio of the mixed material=15, and the total weight of the material is 22kg (when the moisture content is 65 %Time).

[0050] 122g of magnesium hydroxide was mixed with 2kg of water, and then slowly poured into 392ml of phosphoric acid to obtain a granular emulsion. Among them, Mg(OH) 2 and H 3 PO 4 The mass ratio of 1.5:7.4, Mg(OH) 2 and H 3 PO 4 The mass accounts for 8.9% of the total dry matter weight of the material.

[0051] Through proper stirring, the milky particles are evenly attached to the surface of the material, so that the ammonia in the compost and the odor caused by it can be controlled during the compost production an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com