Transmission mechanism and paper feeder using same

A transmission mechanism and automatic paper feeding technology, which is applied to the electric recording process using charge patterns, equipment and instruments of the electric recording process applying charge patterns, etc., can solve the problems of a large number of components, complex coordination, slow response, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

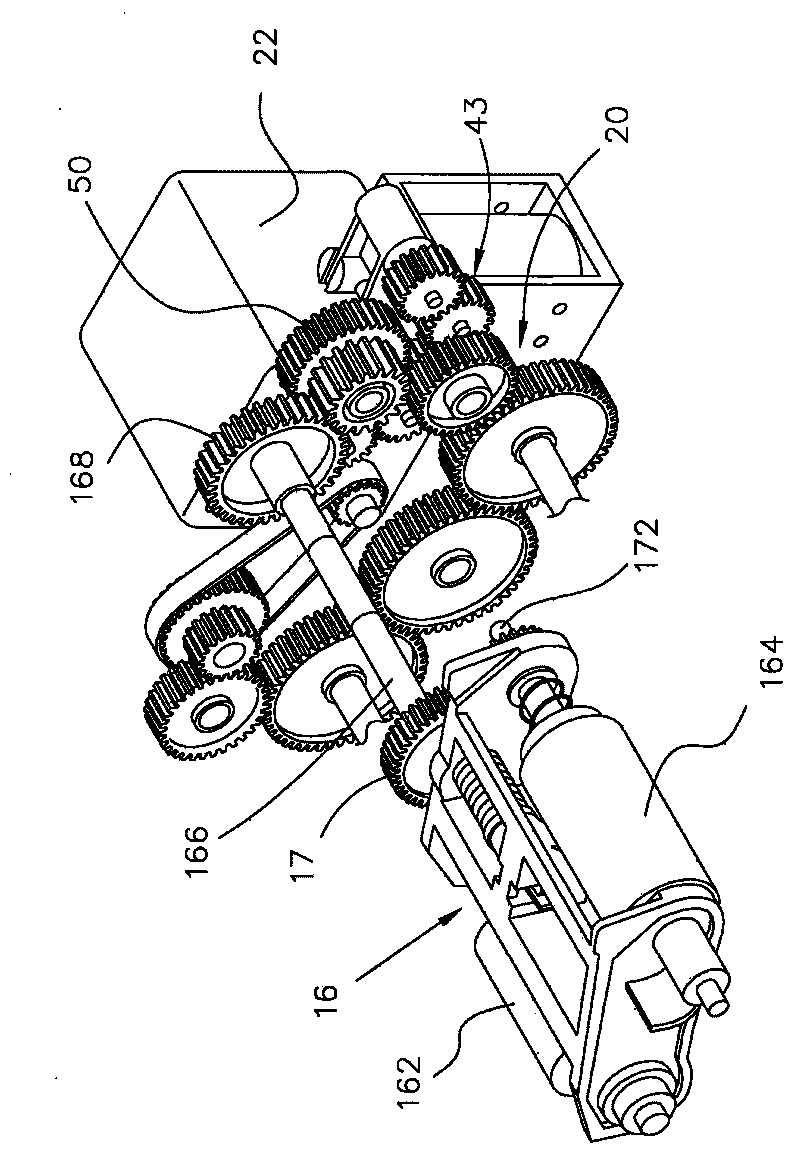

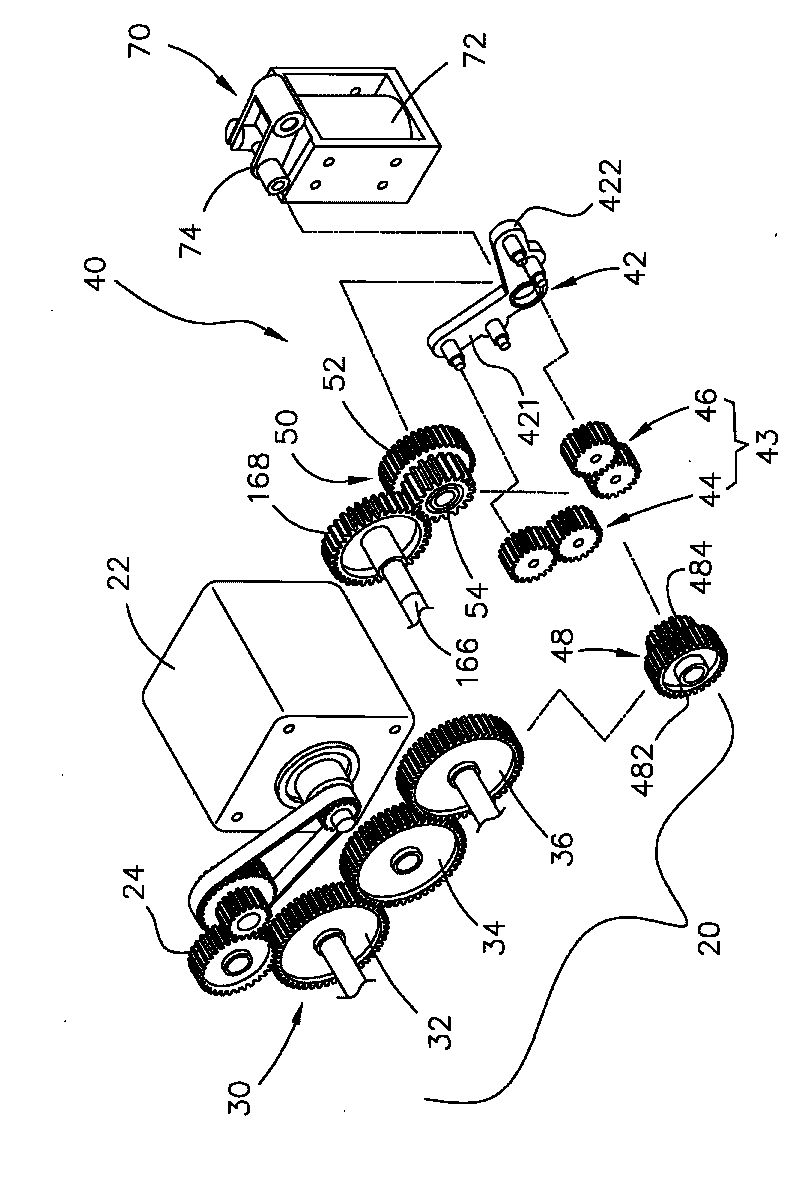

[0055] For the first embodiment of the present invention, please refer to image 3 The arm 42 of the switch assembly 40 has a first arm 421 and a second arm 422 , and there is an angle between the first arm 421 and the second arm 422 .

[0056] The switching gear set 43 is composed of a plurality of gears, including a first gear set 44 and a second gear set 46 . The first gear set 44 has a plurality of intermeshing gears and is disposed on the first arm portion 421 , and the second gear set 46 has a plurality of intermeshing gears and is disposed on the second arm portion 422 .

[0057] The driving gear 48 has a main tooth portion 482 , and a coupling tooth portion 484 is combined with the main tooth portion 482 . The main tooth portion 482 meshes with the third gear 36 of the transmission gear train 30 , and the coupling tooth portion 484 meshes with the first gear set 44 and the second gear set 46 . The driving gear 48 is coaxially pivoted with the arm part 42, and the arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com