Container

A container and box door technology, applied in the field of containers, can solve the problems of crushed wooden floor, box body damage, limited bearing capacity of wooden floor, etc., and achieves the effect of protecting wooden floor, simple structure and convenient manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further illustrate the technical means adopted by the present invention and its beneficial effects, the following is a detailed description in conjunction with preferred embodiments of the present invention and accompanying drawings.

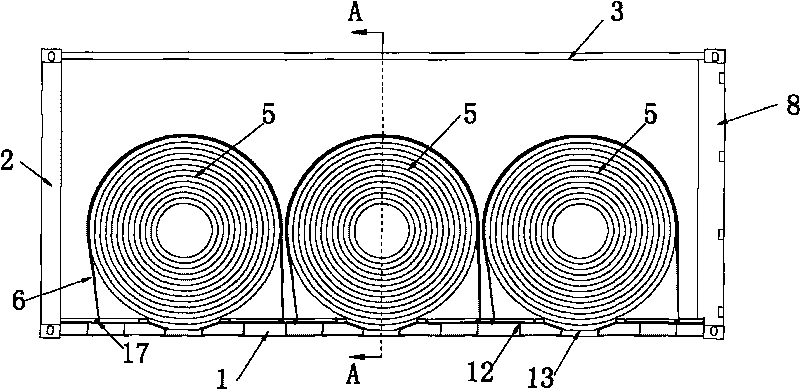

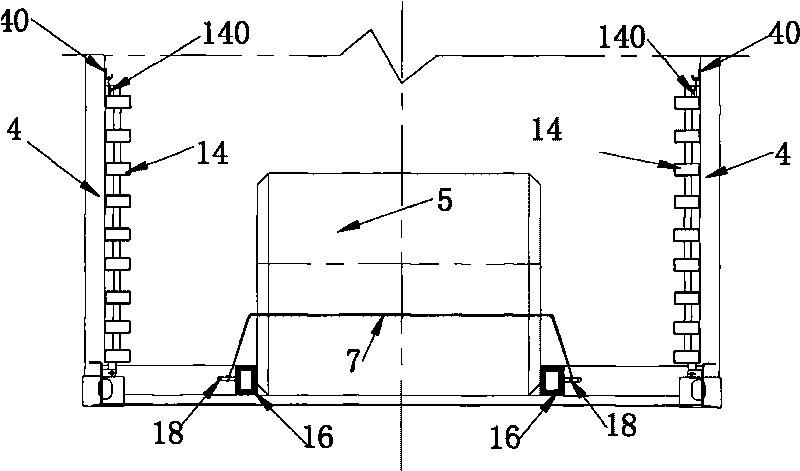

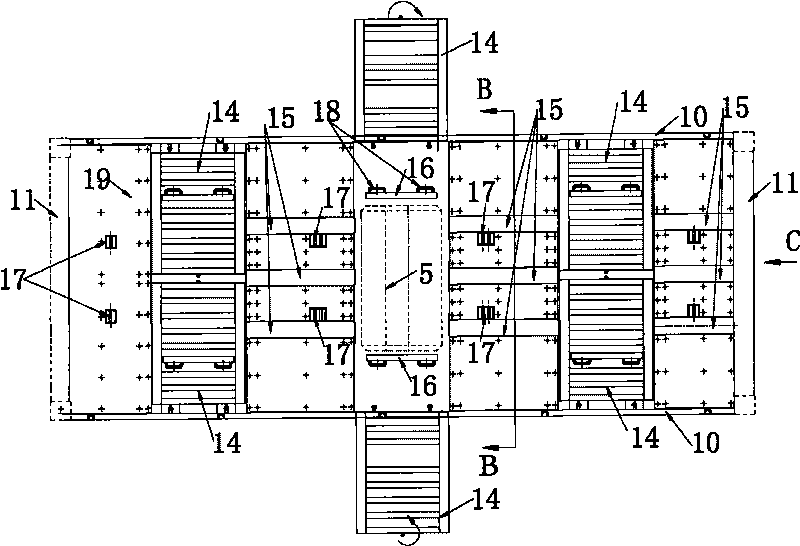

[0028] Such as figure 1 , figure 2 , image 3 As shown, a container includes an underframe 1 for carrying goods, a front wall 2 positioned at its front end, side panels 4 positioned at both sides thereof, a top panel 3 positioned at its top, and a box door 8 positioned at its rear end. The bottom frame 1, the front wall 2, the side plate 4, the bottom plate 3 and the box door 8 are welded and connected to each other.

[0029] The chassis 1 is welded by a pair of side beams 10, a pair of end beams 11, and several middle beams 12. A pair of side beams 10 are located on both sides of the chassis 1, and a pair of end beams 11 are located at both ends of the chassis 1. , several intermediate beams 12 are located between a pair ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com