Digital ink-jet textile printing machine

A digital inkjet and printing machine technology, applied in printing, typewriters, printing devices, etc., can solve the problems of increased influence of ink droplet wind force, difficult transportation, and deviation of cloth running process, so as to ensure printing accuracy and ensure step-by-step The effect of improving precision and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

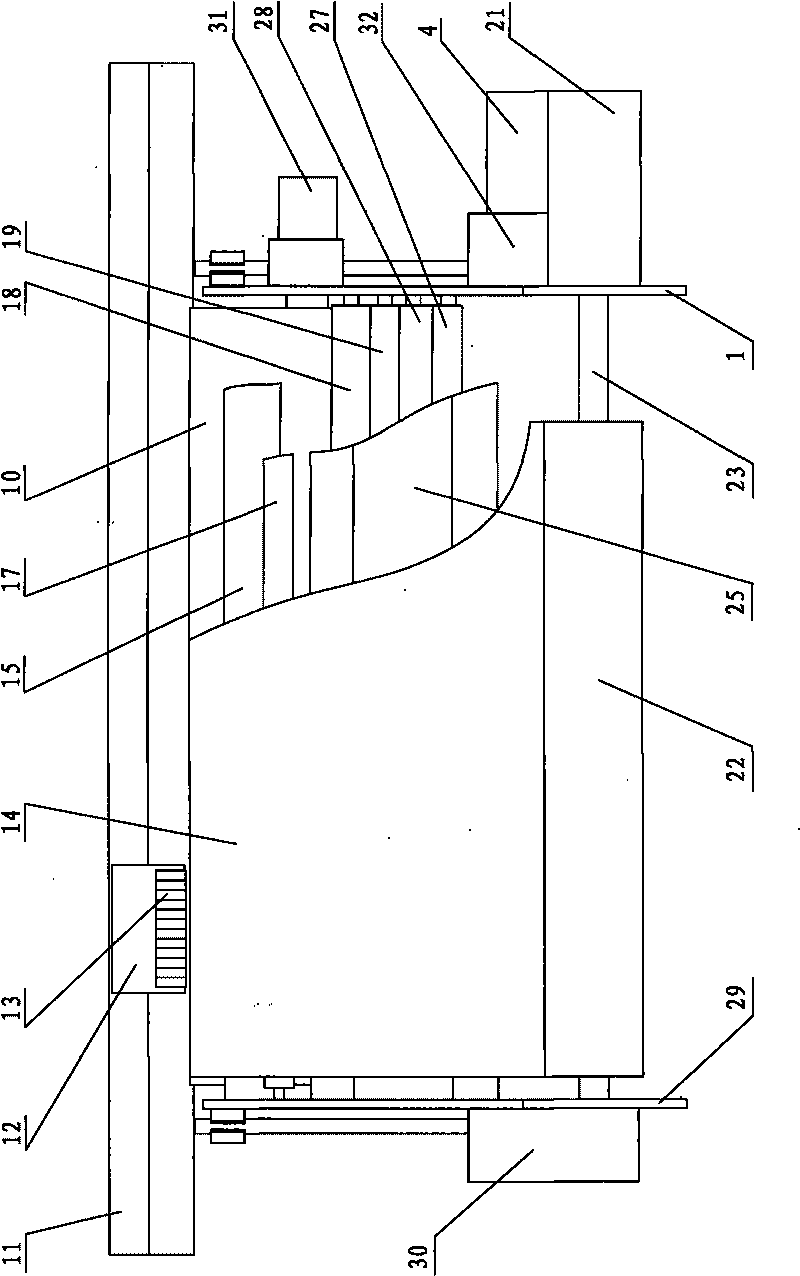

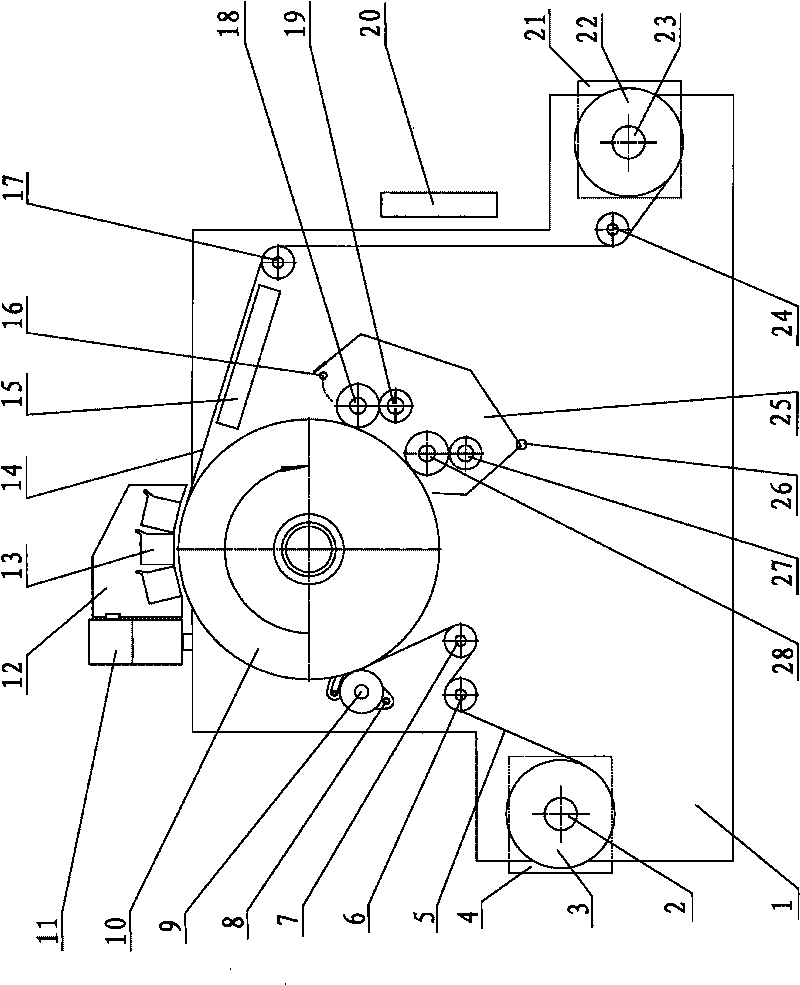

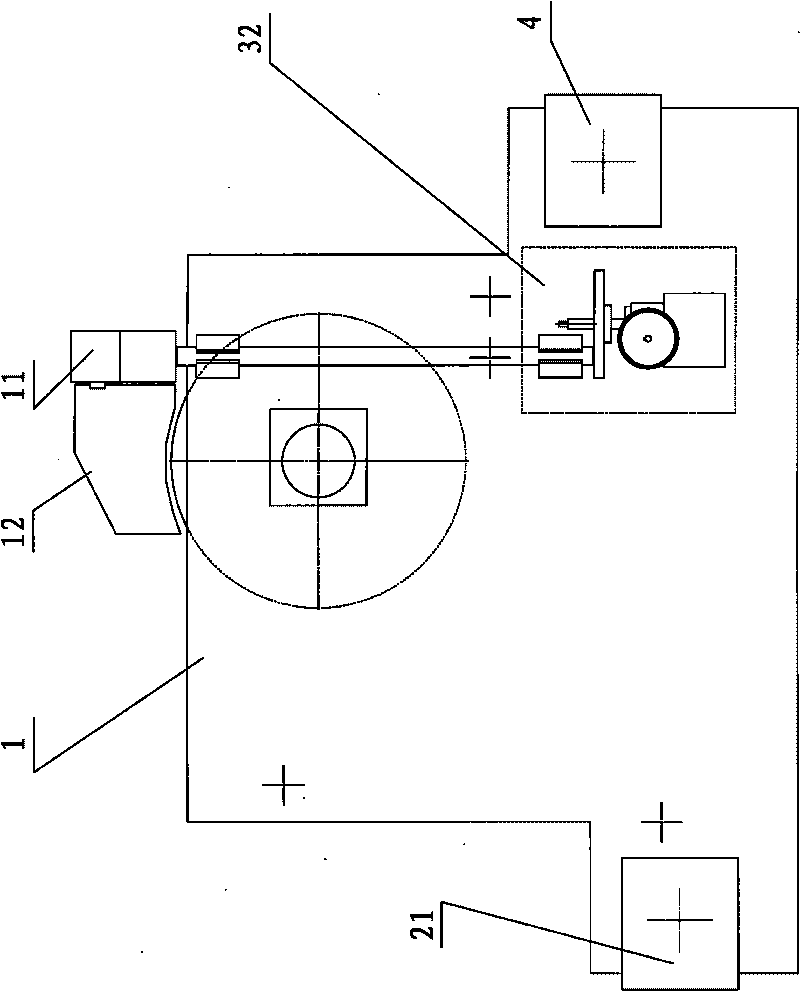

[0030] Such as Figure 1~4 Shown, the present invention comprises left wallboard 29, right wallboard 1 and is installed in the discharge device between two wallboards, receiving device, first guide roller 6, flattening roller 7, leaning against roller 9, main The driving drum 10, the second guide roller 17, the third guide roller 24 and the cleaning device.

[0031] The left and right wall panels 29, 1 are connected by multiple supporting beams 45 to form a main frame structure. The main driving drum 10 as driving roller is rotatably installed on the left and right wallboards 29,1 by bearings, and is driven by the main driving motor 31 installed on the right wallboard 1. The receiving and discharging devices are respectively located on both sides of the main driving drum 10. The discharging device is composed of a discharging roller 2 and a roll 3 to be pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com