Electric locking and rotating joint for auxiliary arm for surgical operation

A technique for surgery and rotary joints, which is used in surgery, medical science and other directions to achieve reliable locking and loosening, strong versatility and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

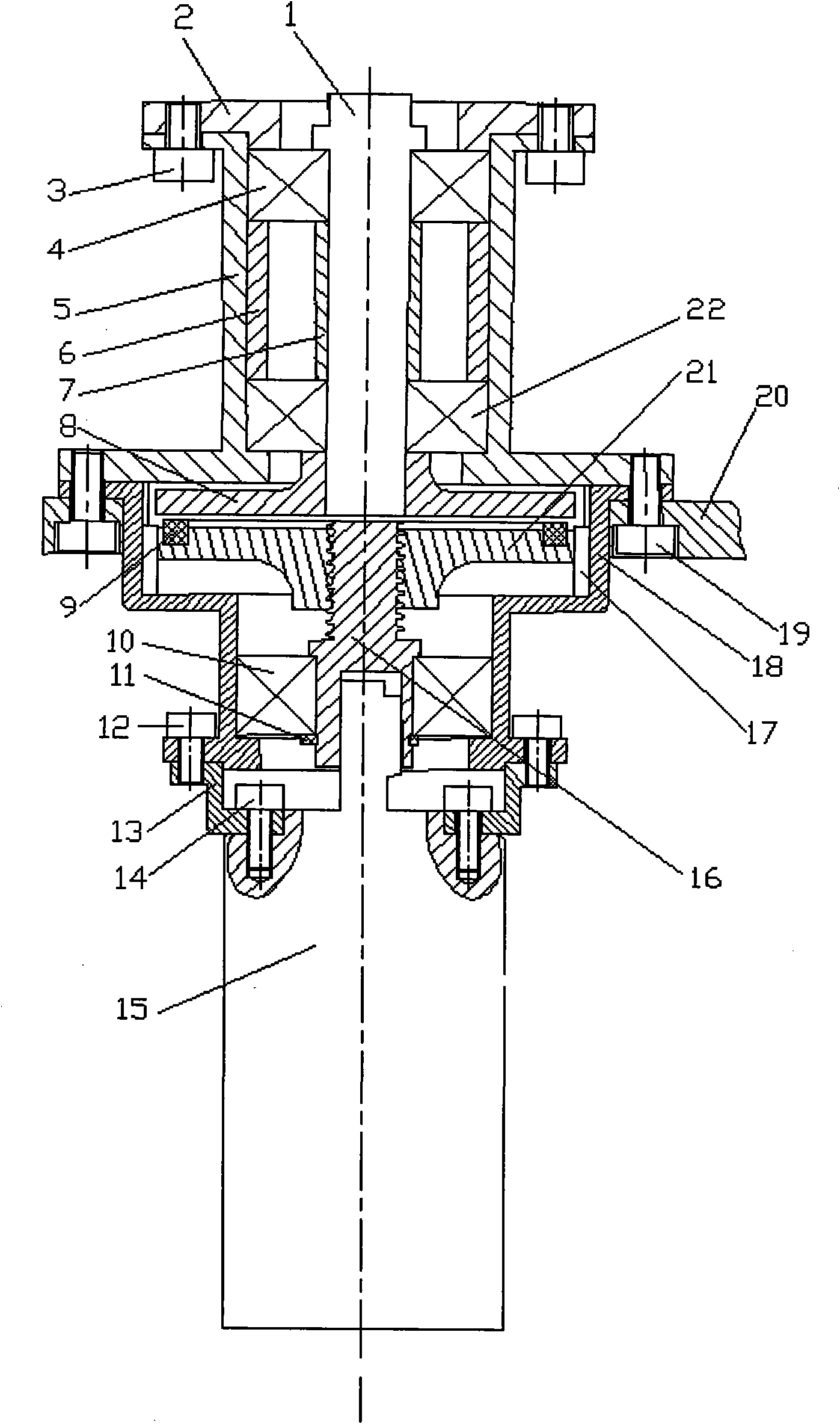

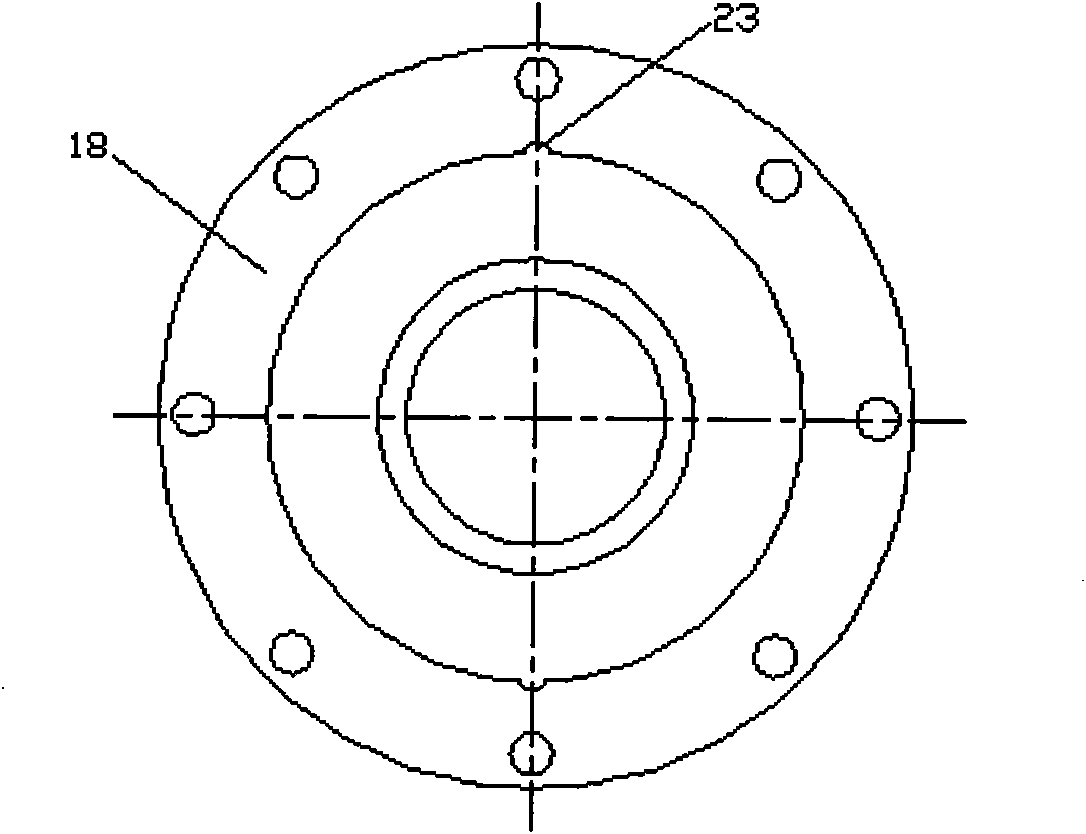

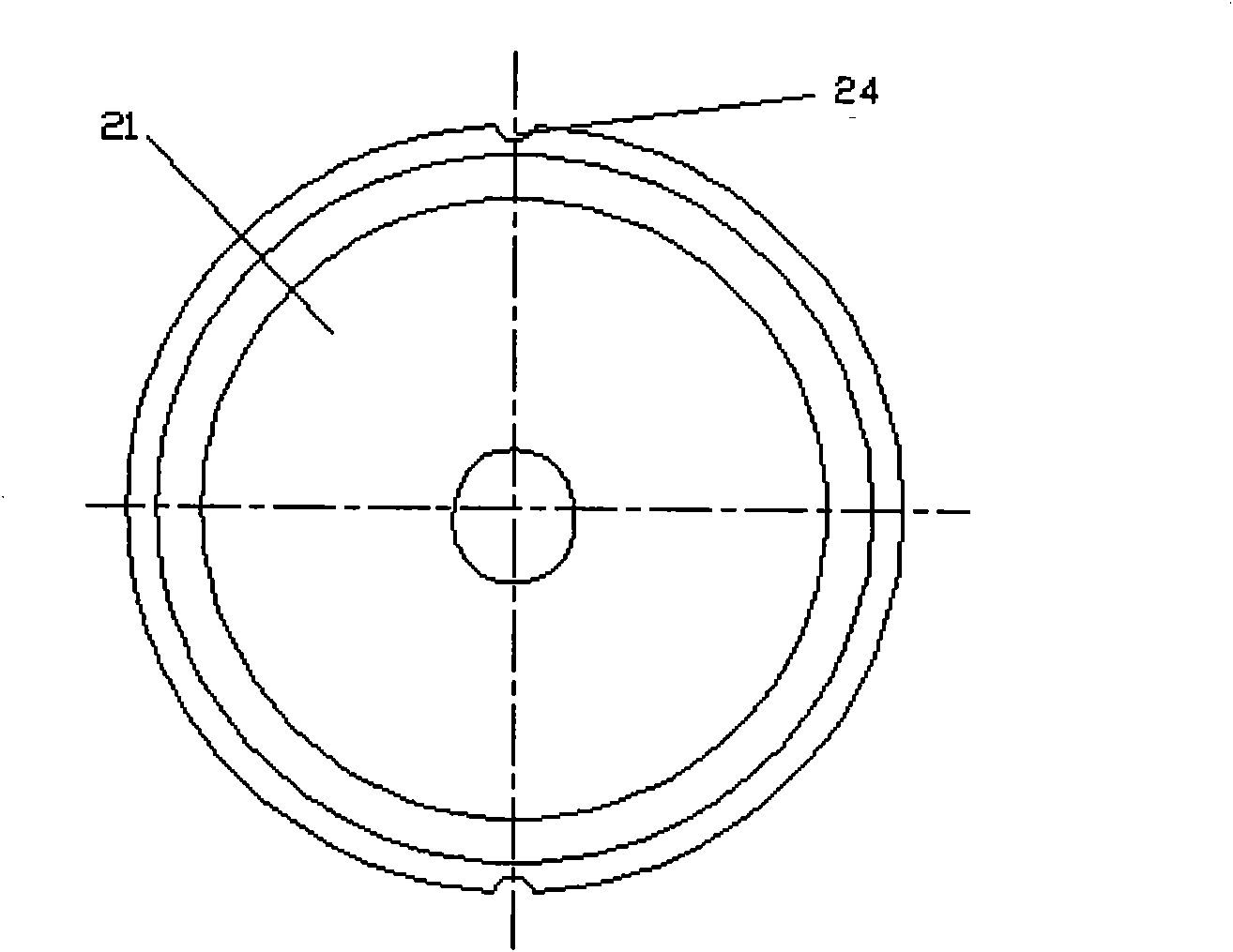

[0034] figure 1 It is a structural schematic diagram of an embodiment of the present invention; figure 2 It is a structural schematic diagram of the locking outer sleeve according to the present invention; image 3 It is a structural schematic diagram of the trapezoidal nut described in the present invention.

[0035] Such as Figure 1 to Figure 3 Shown: Electric locking rotary joint for surgical auxiliary arm, including joint rotation mechanism and joint locking mechanism, the joint rotation mechanism is located on the upper part of the joint locking mechanism, wherein:

[0036] The joint rotation mechanism includes a joint rotating shaft 1, a joint bearing cover 2, a joint bearing seat 5 and a joint chassis 8. The joint rotating shaft 1 is an output shaft of the present invention, which is connected with a load, and the joint bearing cover 2 is located on the upper part of the joint rotating shaft 1, and its It is fixedly connected with the joint bearing seat 5 located ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap