Liquid material feeding device and method for cooking device

A liquid material and feeding device technology, applied in cooking utensils, applications, household appliances, etc., can solve the problems of long waiting time, slow liquid flow, and reducing the working efficiency of cooking equipment, so as to reduce waiting time, easy control, fast and The effect of accurate delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

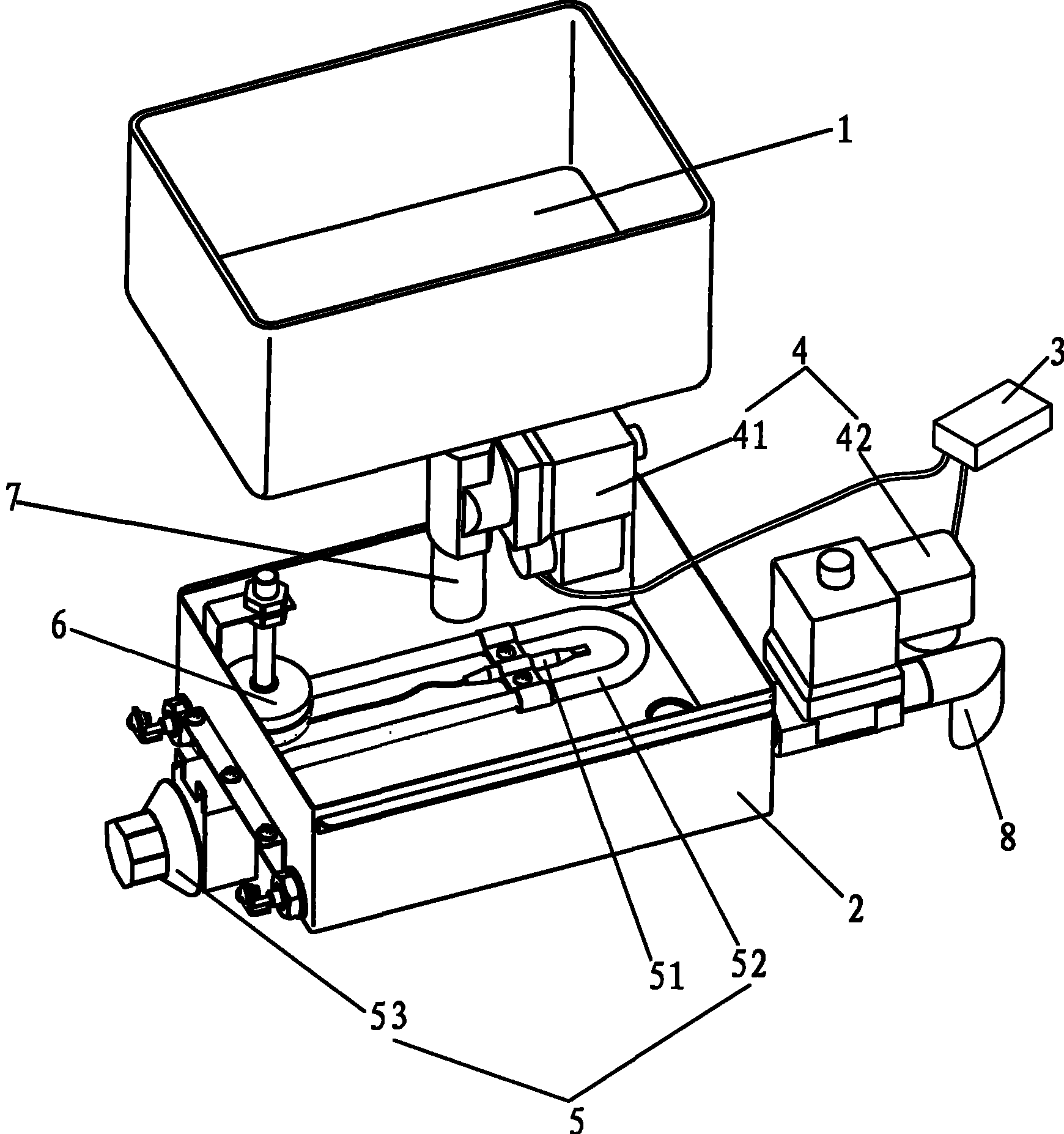

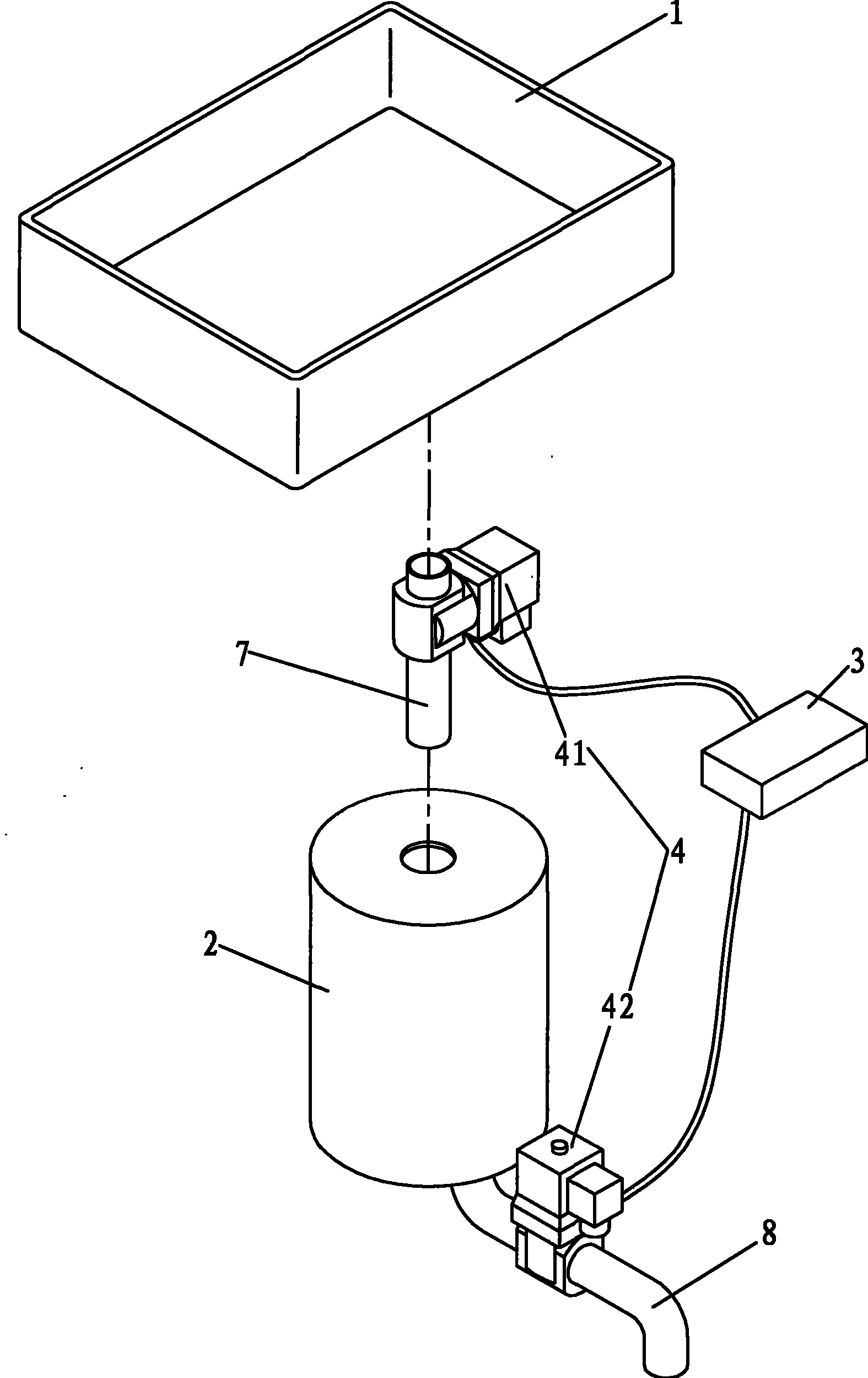

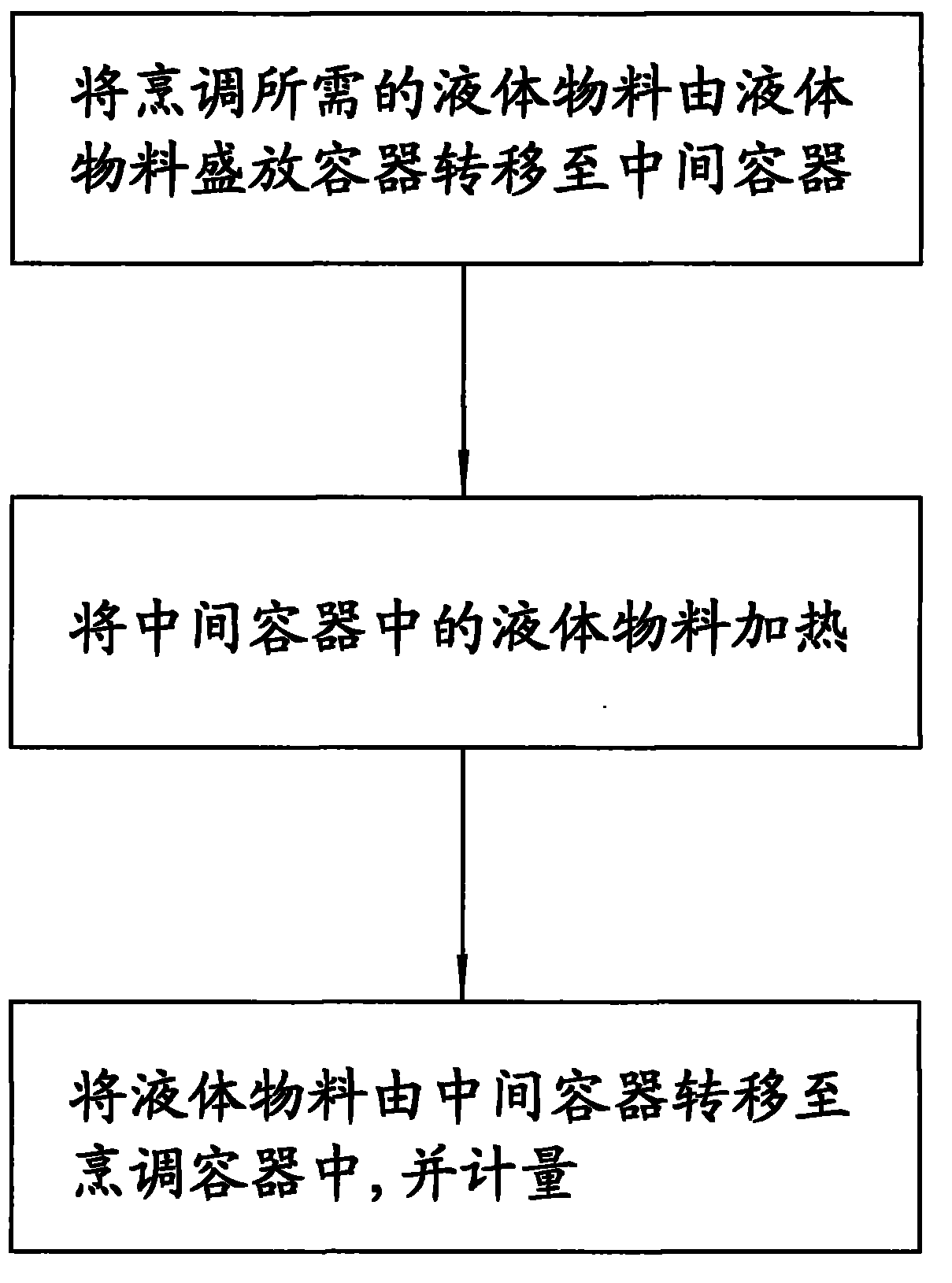

[0042] Such as figure 1 As shown, the present invention discloses a device for feeding liquid materials, which includes a liquid material holding container 1, an intermediate container 2, a controller 3, a material transfer device 4, a temperature control device 5 and a metering device 6, wherein:

[0043] The liquid material holding container 1 injects liquid material into the intermediate container 2 through the pipeline 7 .

[0044] The intermediate container 2 puts the liquid material into the pot body (not shown in the figure) of the cooking machine through the pipeline 8 .

[0045] The material transfer device 4 is a solenoid valve, which includes a solenoid valve 41 on the pipeline 7 and a solenoid valve 42 on the pipeline 8 .

[0046] Temperature control device 5 comprises detection device 51, heating device 52 and temperature control switch 53, and detection device 51, in the present embodiment, it adopts the thermocouple that belongs to temperature sensor, and therm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com