Online detection and calibration method for Hall current sensor

A technology of Hall current and calibration method, which is applied in the direction of instruments, measuring devices, measuring electrical variables, etc., to achieve the effect of solving bias errors, improving measurement accuracy, and avoiding unnecessary losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

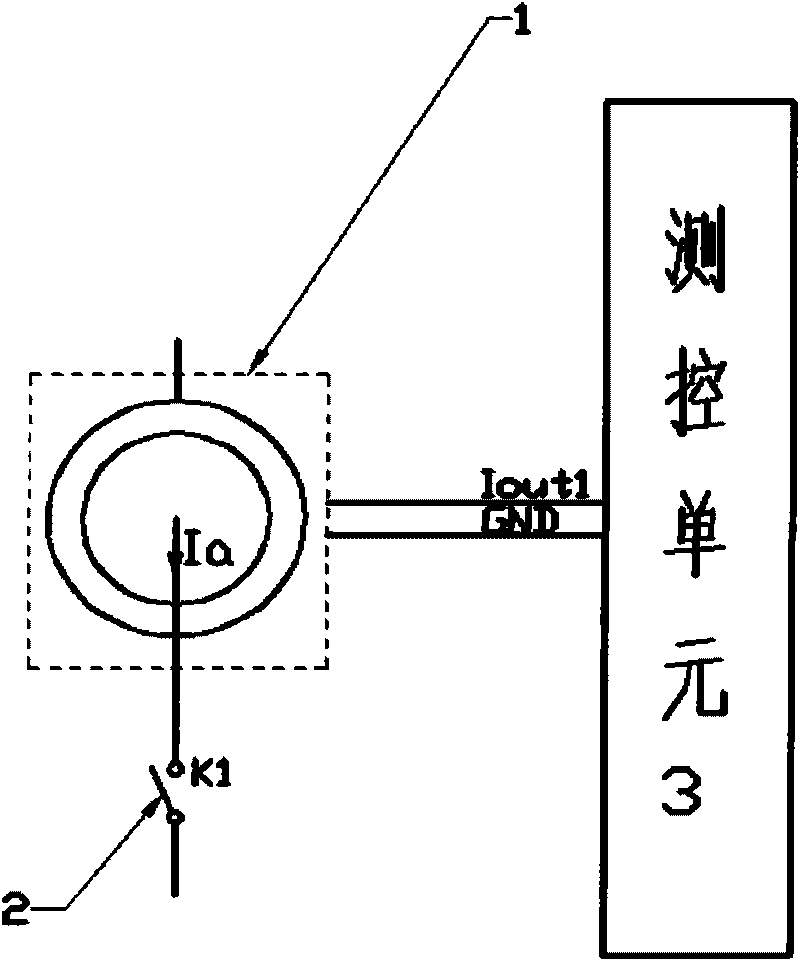

[0016] figure 1 Shown is the block diagram of the traditional Hall current sensor measurement method, in the figure (1) is the Hall current sensor for measurement, Ia is the measured current, (2) is the switch of the measurement current loop, (3) is the measurement and control unit, with It is used to receive the output current signal of the measuring sensor.

[0017] The input measurement circuit of the Hall current sensor (1) for measurement is Ia, and the output circuit is connected with the measurement and control unit (3). Its main feature is to complete a single measurement function. When the measured circuit has a current Ia passing through it, the sensor output signal circuit will get the Iout1 current signal output according to a fixed ratio. This signal will be processed by the measurement and control unit to obtain the measured value. If the Hall current sensor is biased or damaged, the sensor output signal circuit will not get the current signal output according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com