Mining car measurement monitoring system based on image processing

A monitoring system and image processing technology, applied in the field of mine car measurement monitoring system based on image processing, can solve problems such as failure to act in time, image data not automatically participating in the reliability and authenticity of weighing data, and affecting the accuracy of measurement data. , to achieve the effect of authenticity and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

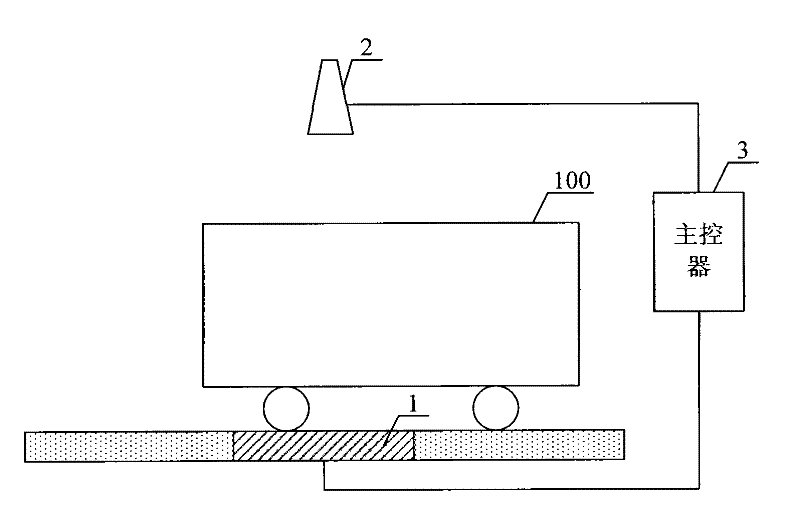

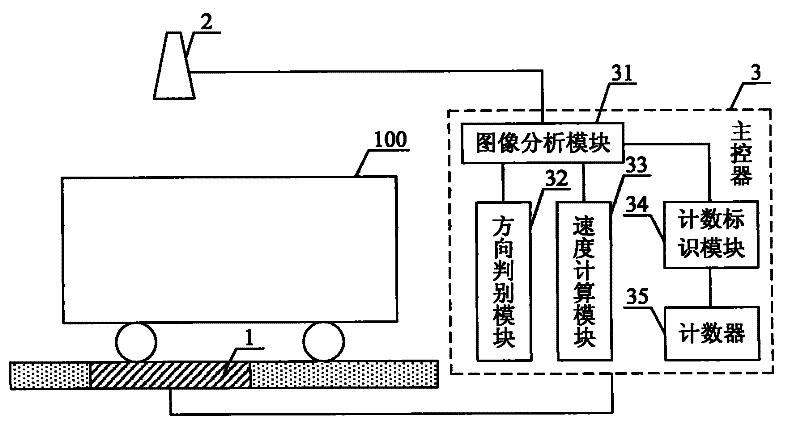

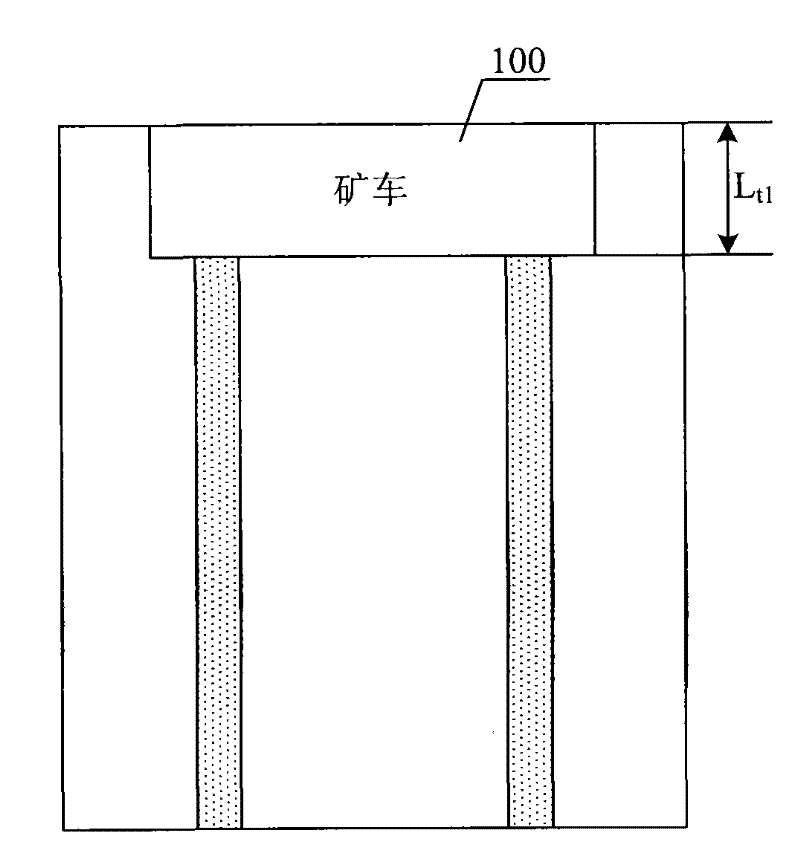

[0019] figure 1 It is a schematic structural diagram of the first embodiment of the image processing-based mining vehicle metering and monitoring system of the present invention. Such as figure 1 As shown, the mine car metering monitoring system includes: a track sensor 1 for weighing the mine car 100, and also includes: a camera 2 located directly above the track sensor 1 and a master controller 3 connected to the camera 2 in communication, Wherein, the main controller 3 judges the running direction of the mine cart 100 according to the mine cart image data collected by the camera 2 , calculates the running speed of the mine cart 100 , and counts the mine cart 100 .

[0020] In the mine car measurement and monitoring system based on image processing provided in this embodiment, the main controller 3 discriminates the running direction of the mine car 100 by receiving the mine car image data collected by the camera 2, calculates the running speed of the mine car 100, and calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com