Concrete-enrockment mixed dam and construction method thereof

A technology of concrete and mixed dams, which is applied in the direction of dams, barrages, gravity dams, etc., can solve the problems of strong dependence on terrain and geological conditions, poor earthquake resistance, etc., and achieve the goals of reducing dam volume, good integrity, and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment one graded filling concrete-rockfill hybrid dam

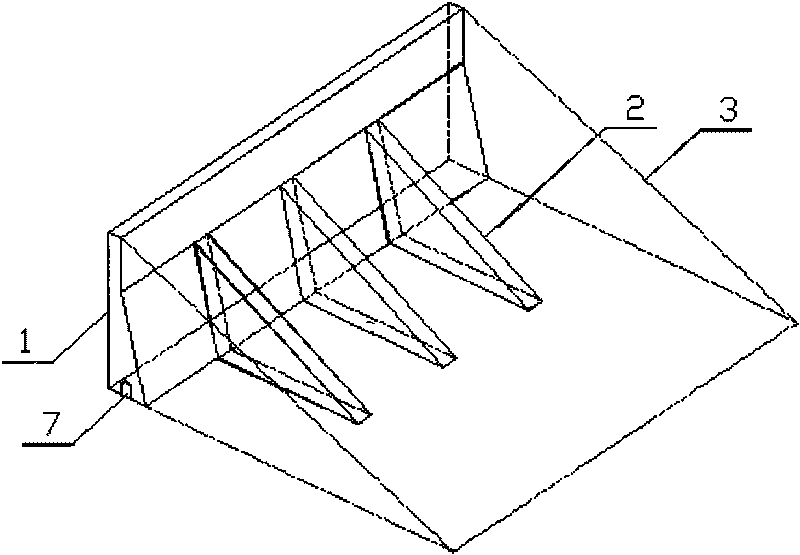

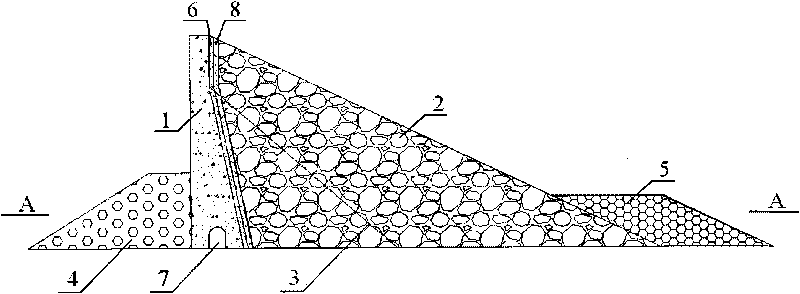

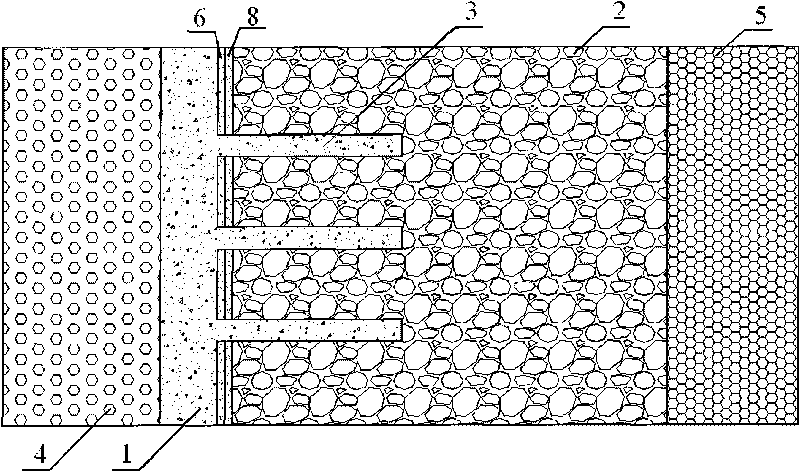

[0028] Such as figure 1 , 2 As shown in , 3, a new type of concrete-rockfill hybrid dam is composed of concrete dam body 1, rockfill body dam body 2, comb-shaped tooth connecting section 3, upstream rockfill ballast 4, downstream rockfill ballast 5, pad The layer 6 and the transition layer 8 are composed, and the corridor 7 is set at the bottom of the concrete dam body 1 at the same time. The upstream dam body of the mixed dam adopts the concrete dam body 1, and the downstream dam body adopts the rockfill body 2. The comb-shaped tooth connecting section 3 is a group of triangular concrete slab walls arranged in a comb-like shape, which is integrally poured with the concrete dam body 1, extends from the concrete dam body 1 to the rockfill dam body 2 and penetrates into the rockfill dam body 2 middle.

[0029] When the dam height is high, the construction needs to be carried out according to the graded filli...

Embodiment 2

[0030] Embodiment 2 integrally filled concrete-rockfill hybrid dam

[0031] The structure of the mixing dam is the same as in Embodiment 1.

[0032] When the dam height is not very high, the overall filling method can be adopted. When the overall filling is completed, the concrete dam body 1 and the comb-shaped tooth connecting section 3 are constructed first, and the two are continuously poured to the dam crest, and the two are integrally poured; after the construction of the concrete dam body 1 and the comb-shaped tooth connecting section 3 is completed, start The cushion layer 6 and the transition layer 8 are constructed, and the rockfill dam body 2 is filled at the same time. The two are carried out simultaneously, and the rockfill material must be fully rolled and compacted; Actual conditions during construction, the upstream rockfill ballast 4 and the downstream rockfill ballast 5 can also be carried out simultaneously when the dam body is filled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com