Camera measurement based automatic leveling system and method of spreading machine

A camera measurement, automatic leveling technology, applied in digital camera measurement, paver leveling parameter measurement, automatic control field, to achieve the effect of reasonable price, high measurement accuracy, easy to achieve automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

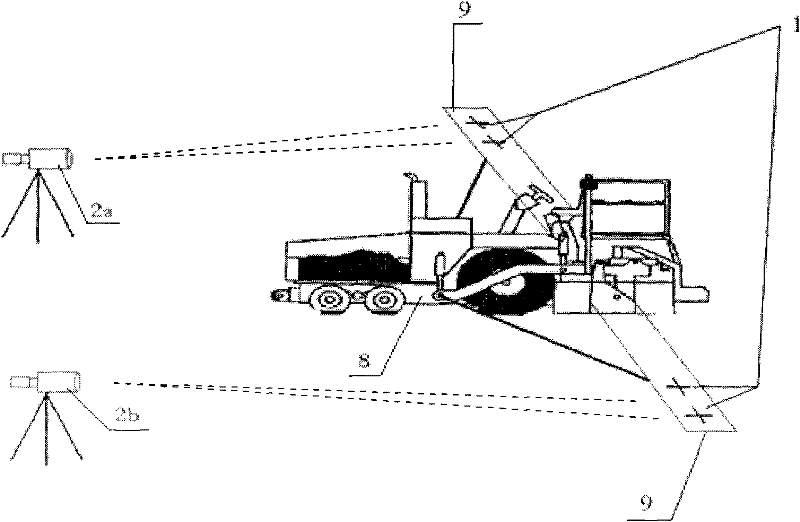

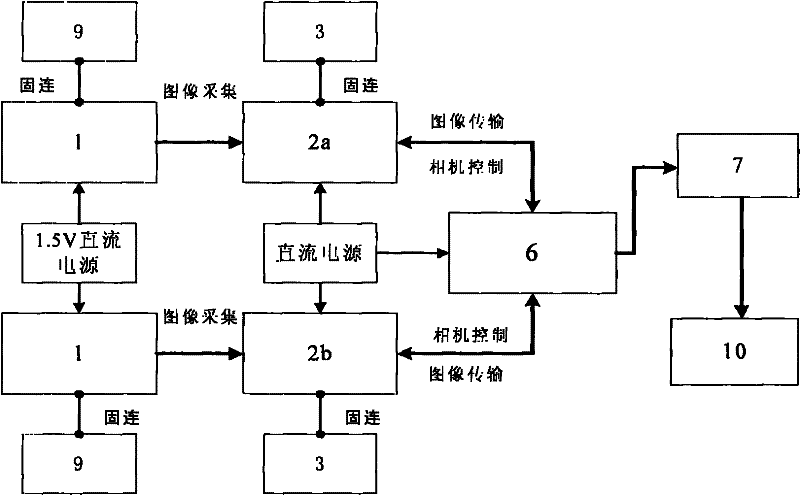

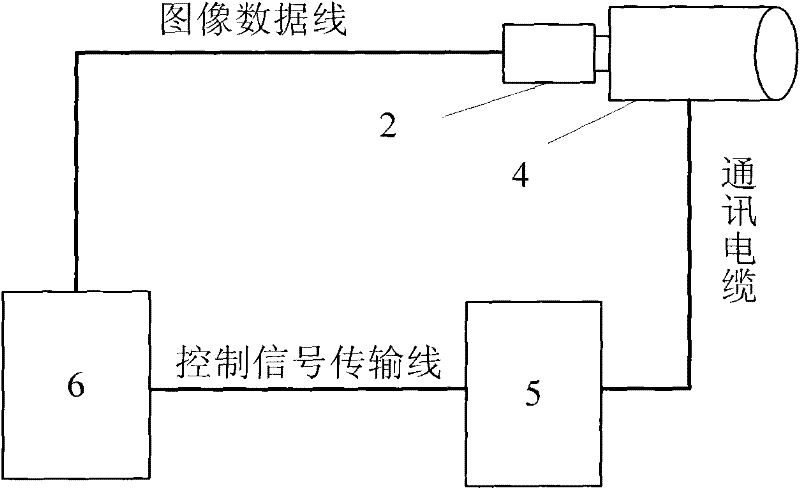

[0043] The paver automatic leveling system based on camera measurement described in this embodiment consists of artificial luminous signs in the shape of "ten", cameras, camera installation platforms, electric three-variable lenses, decoding controllers, DSP image processors and wireless transceivers. Module composition.

[0044] This embodiment uses the camera measurement method to quickly and automatically measure the manual cooperation marks fixed on the screed to obtain the position offset information of the screed, and then obtain the flatness information of the ground, and then feed it back to the control system of the paver. Its specific implementation steps are as follows:

[0045] 1) Fix four manual cooperation marks on the left and right sides of the paver screed, and measure two manual cooperation marks each time: if figure 1 , 2 As shown, two infrared light-emitting signs are respectively fixed on both sides of the screed 9 as the artificial cooperation sign 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com