Group control device of blast furnace gas bag-type dust removing system for conveying ash in pipeline

A technology of bag dust removal and blast furnace gas, which is applied in dust collectors, separation methods, and dispersed particle filtration, etc., can solve the problems of insufficient protective interlock control, improve operating efficiency, increase equipment service life, and extend equipment service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

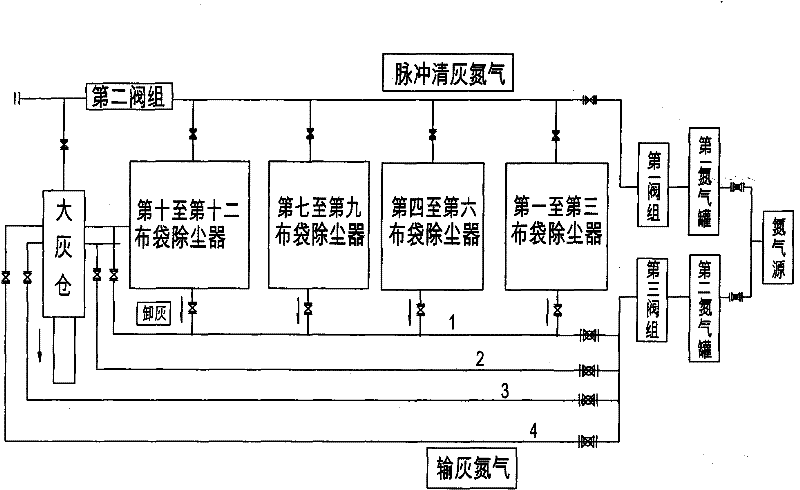

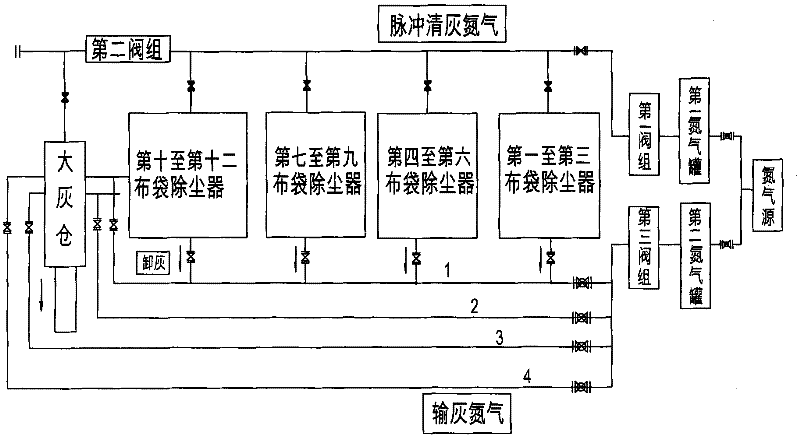

[0020] The number of multi-path ash nitrogen pipelines added depends on actual needs. In this embodiment, there are three pipelines, which are respectively the 2nd, 3rd and 4th ash nitrogen pipelines. In addition to the first ash nitrogen pipeline, there are four ash nitrogen pipelines in total.

[0021] The quantity of said bag filter depends on the actual needs. In this embodiment, there are four sets of bag filters, and the number of each set of bag filters is 3. Among them, the first group of bag filters are the first to third bag filters; the second group of bag filters are the fourth to sixth bag filters; the third group of bag filters are the seventh to ninth bag filters; The fourth group of bag filters are the tenth to twelfth bag filters.

[0022] When the system is configured with a closed pipeline ash conveying system, the pressure control of the third valve group in the nitrogen pressure stabilizing valve group is changed; Until air resistance is formed, the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com