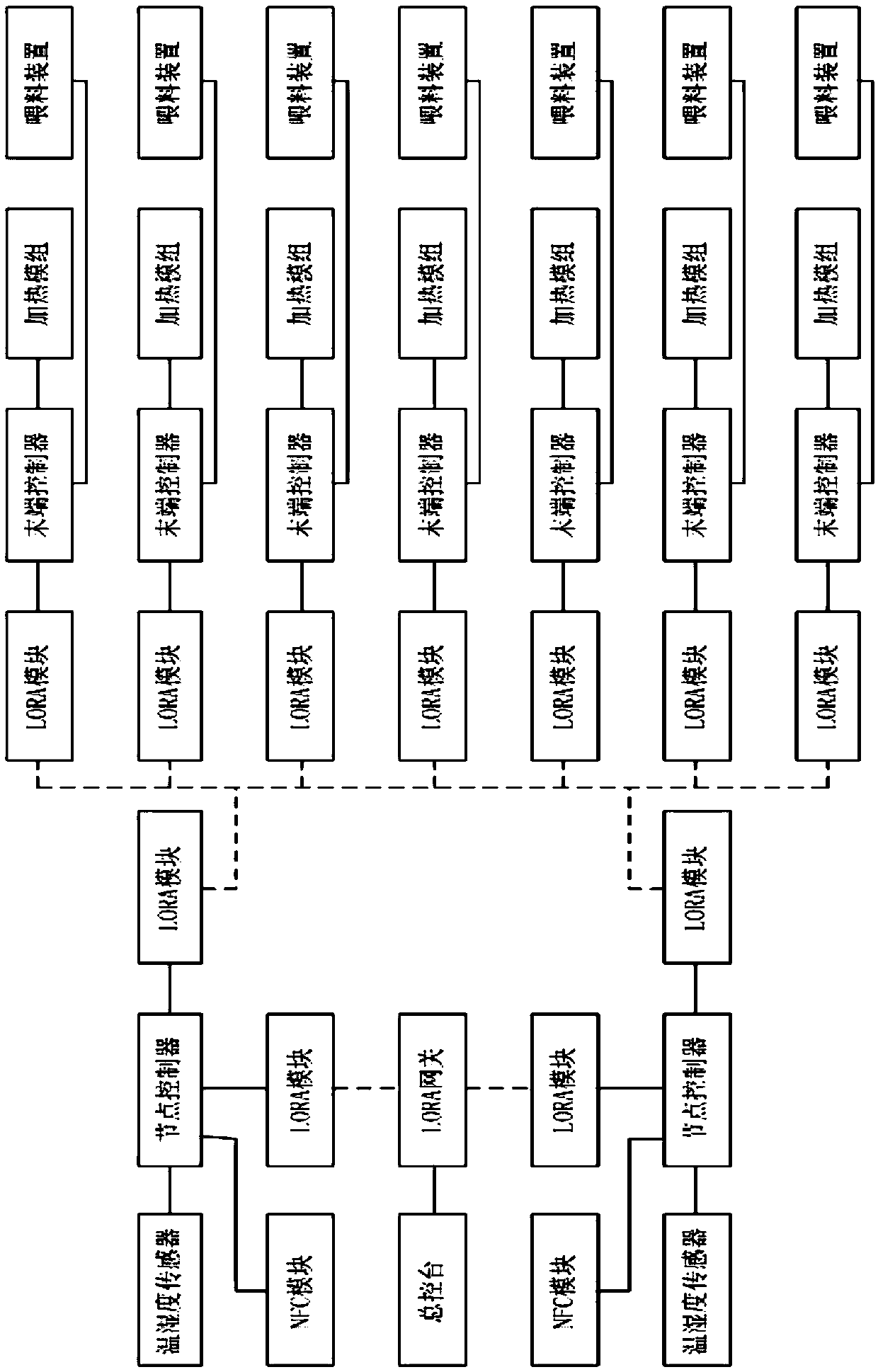

Control method for control console of self-control aquaculture farm

A control method and farm technology, applied in the direction of program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of easy operation errors, troublesome adjustment of control methods, disordered distribution of breeding species, etc., and achieve the goal of reducing the cost of electronic components Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

[0022] The present invention provides a control method for the master console of a self-controlled aquaculture farm, comprising the following steps:

[0023] ① Receive environmental data: send data request signals to the node controller one by one, and wait to receive the environmental data fed back by each node controller;

[0024] ②Establish a distribution map: update the environmental data distribution map by combining the received environmental data with the location information of the internally stored node controllers;

[0025] ③Calculation of control value: According to the position of each culture pond in the environmental data distribution map, the environmental data of each culture pond is obtained, and then the heating intensity and feeding cycle are calculated according to the control target value of each culture pond; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com