Quick pulping method of soymilk maker

A soymilk machine and pulping technology, which is applied to dairy products, beverage preparation devices, milk substitutes, etc., can solve the problems of long pulping time, etc., and achieve the effects of sufficient cooking, uniform heating and shortened time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

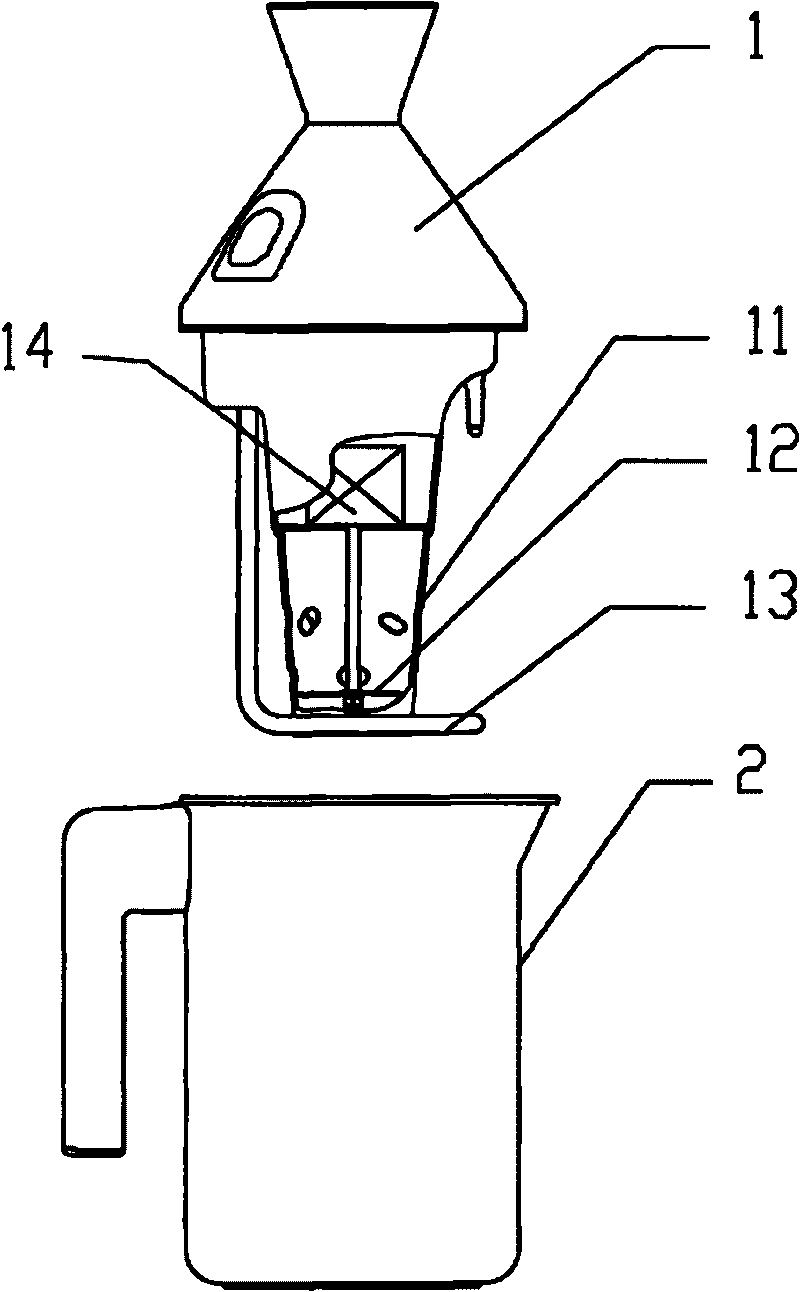

[0027] As the soya-bean milk machine that realizes the rapid pulping method of the present invention, as figure 1 As shown, it includes a machine head 1, a cup body 2, a motor 14, a pulverizing device and a heating device. The pulverizing device includes a pulverizing cutter 12, and the pulverizing cutter 12 is fixed at the end of the motor shaft. In this embodiment, the motor 14 Built in the head 1, the head 1 is placed above the cup body 2, the heating device is a heating tube 13, when the capacity of the soybean milk machine is 1000ml, the heating power of the heating tube 13 is 1500W, the crushing device An auxiliary crushing part is also included, and the auxiliary crushing part is a deflector 11 .

[0028] Of course, optionally, the heating device can also be an electric heating plate, or the heating function can also be realized by using electromagnetic heating, microwave heating and other heating methods; the auxiliary pulverizing part can also be a turbulence device o...

Embodiment 2

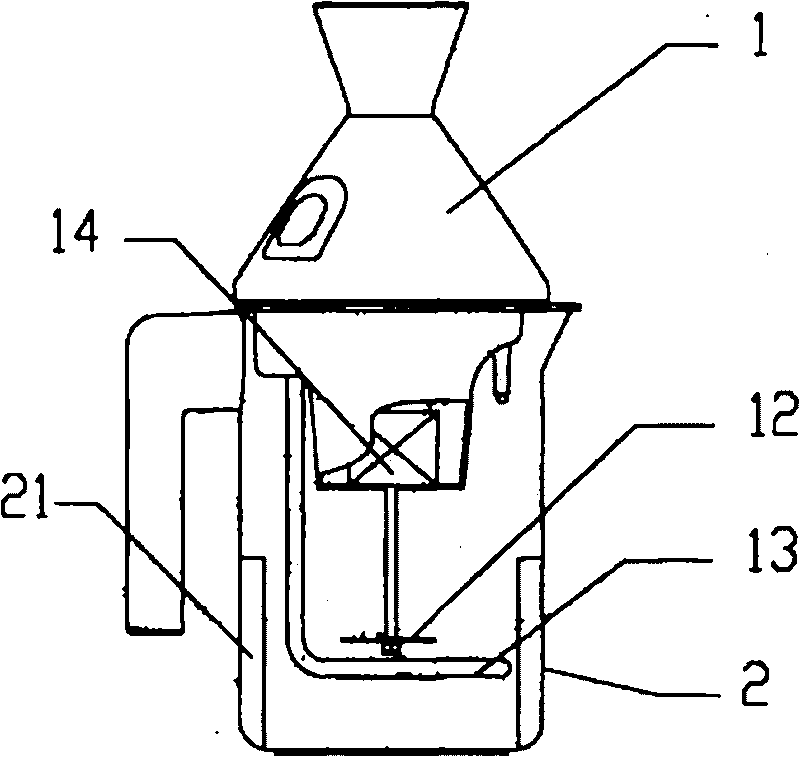

[0040] In the present embodiment, as the soya-bean milk machine that realizes the rapid pulping method of the present invention, such as image 3 As shown, the difference from the first embodiment is that the auxiliary crushing part is a baffle 21 , and the baffle 21 is arranged on the cup body 2 . When the capacity of the soybean milk machine is 600ml, the heating power of the heating tube 13 is 1200W.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com