Energy-saving resonance type electric actuator

An actuator and electric technology, applied in the direction of electrical components, electromechanical devices, etc., can solve the problems of power amplifier size and weight increase, inconvenient engineering application, high energy consumption, etc., and achieve the effect of compact structure, improved efficiency, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

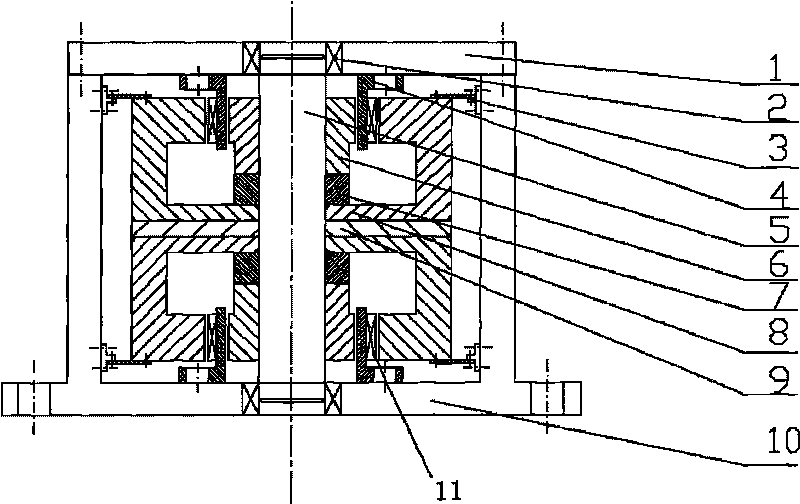

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0019] The invention consists of a casing, an excitation coil group, a leaf spring, a mover and a bearing. The upper cover 1 and the base 10 constitute a housing. A coil 11 is wound on the bracket 4 to form an excitation coil group and is fixedly connected to the upper end cover 1 by screws. The yoke 6, the yoke 8, the permanent magnet 7 and the spacer disk 9 are connected in series and fixed on the guide shaft 5 to form a mover. Both the yoke 6 and the yoke 8 are good magnetically conductive materials. The permanent magnet 7 is end-face polarized, so that the yoke 6, the permanent magnet 7, and the yoke 8 form a closed magnetic circuit. The bearing 2 is installed in the upper end cover 1 and the base 10, and guides the mover. The yoke 8 is connected to the base 10 via a leaf spring 3 .

[0020] Now explain the working principle of the above actuator. When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com