Quick joint

A fast and connecting hole technology, which is applied in the direction of pipe/pipe joint/pipe fitting, sealing surface connection, passing components, etc., can solve the problems of reducing the qualified rate, increasing the difficulty of processing, and scrapping the joint, so as to achieve convenient snap-in mechanism or sealing circle, low production requirements, and easy maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

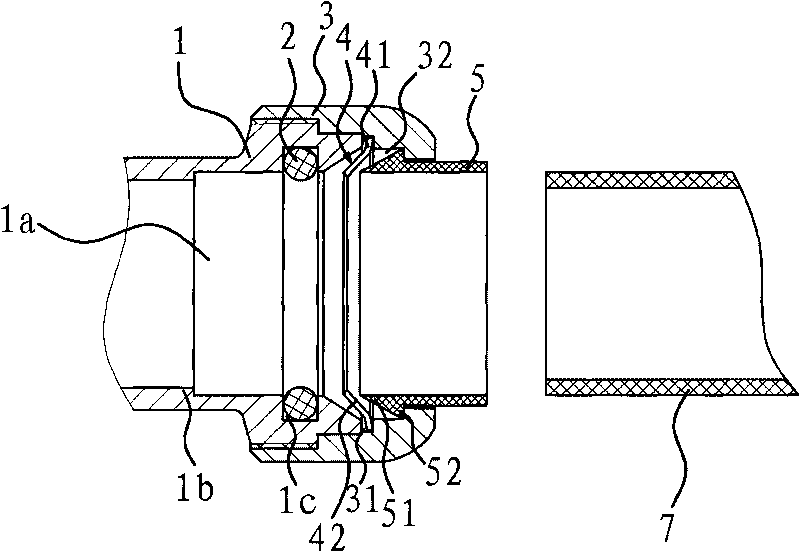

[0028] Such as figure 1 As shown, the quick connector includes a body 1 , a sealing ring 2 , a clamping mechanism, and a fixing cap 3 .

[0029] Specifically, the body 1 is cylindrical and has a connection hole 1a, and an annular bead 1b is provided on the inner wall of the connection hole 1a, and the end face of the connecting pipe 7 inserted into the connection hole 1a can abut against the end face of the ring bead 1b, thereby Prevent the connecting pipe 7 from being inserted into the body 1 too much. There is also an annular groove 1c on the inner wall of the connection hole 1a, and the annular groove 1c is located on the outside of the annular bead 1b, and the sealing ring 2 is fixed in the annular groove 1c, and the sealing ring 2 can circumferentially seal the socket inserted into the connecting hole. Take over 7.

[0030] The fixed cap 3 is cylindrical and one end is fixed on the body 1 and the clamping mechanism is fixed at the entrance of the connection hole 1a (the...

Embodiment 2

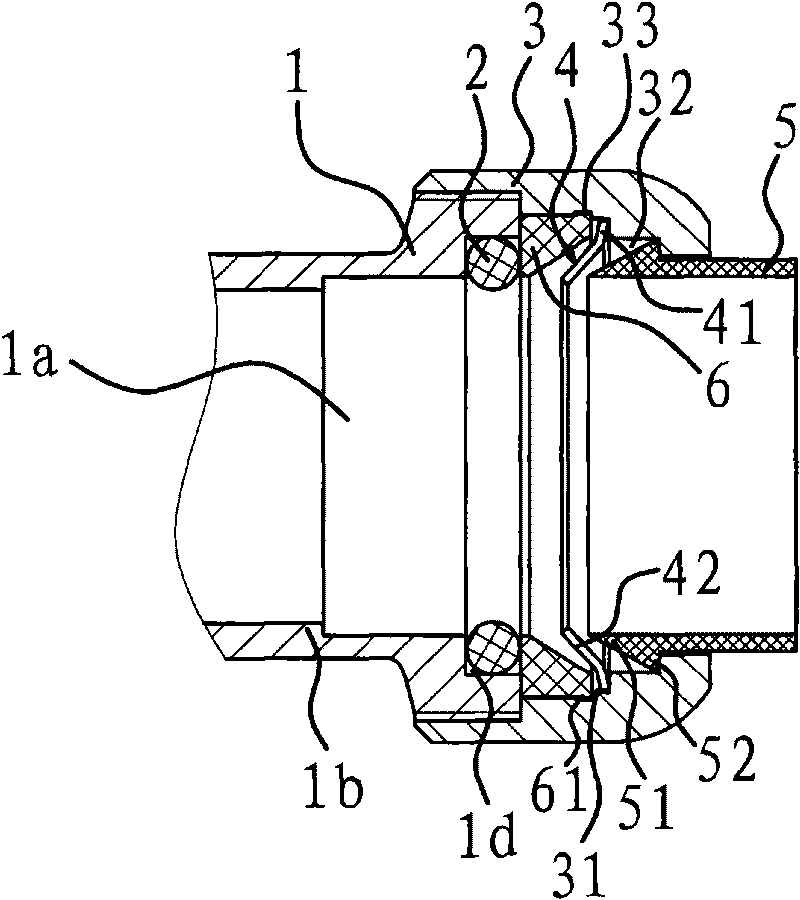

[0035] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: figure 2 As shown, the entrance of the connecting hole 1a is provided with an annular concave shoulder 1d, and the sealing ring 2 is embedded on the annular concave shoulder 1d. There is an annular ferrule pad 6 inside the annular step 1, one end of the ferrule pad 6 is against the ring frame 41 of the collar 4, and the other end is against the end surface of the body 1 and the end is pressed and sealed at the same time Ring 2, so that the sealing ring 2 is fixed on the annular concave shoulder 1d. The inner edge of the abutting surface of the ferrule pad 6 and the collar 4 has a conical installation portion for installing the claw 42 and allowing the claw 42 to have a space to expand.

[0036] An annular positioning groove 33 is formed on the side wall of the annular step one 31, and a positioning ring 61 is provided on the outer wall of the ferrule ...

Embodiment 3

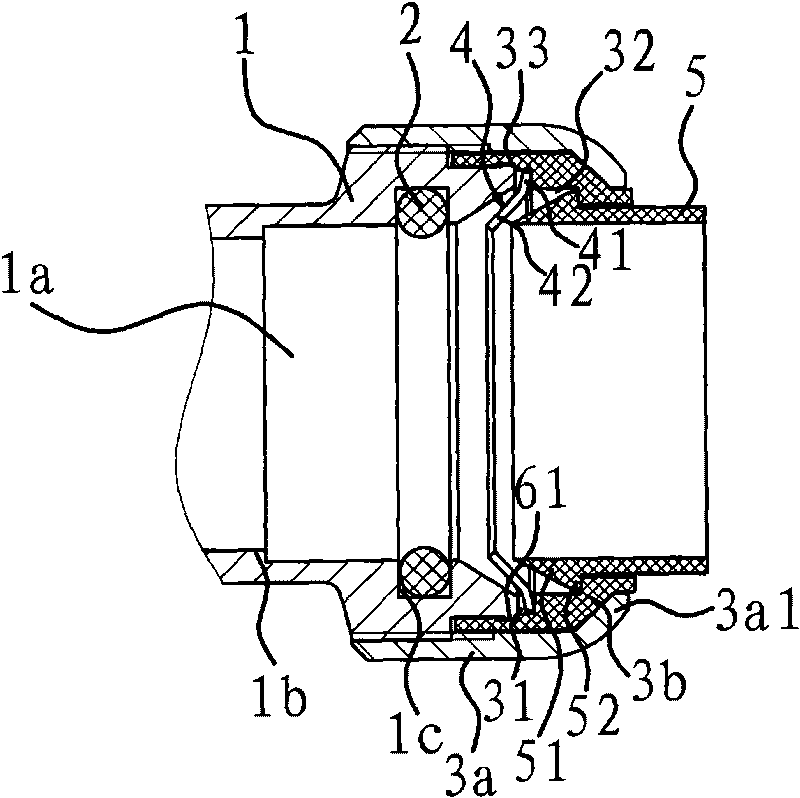

[0038] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: image 3As shown, the fixed cap 3 includes a cap body 1 3a fixedly connected to the body 1 and a cap body 2 3b located in the cap body 1 3a, and the above-mentioned annular step 1 31 and annular step 2 32 are all located on the inner wall of the cap body 2 3b . The outer end surface of the first cap 3a has a rim 3a1 facing the axis, and the outer end of the second cap 3b presses against the rim 3a1 of the first cap 3a. Annular positioning groove 33 is opened on the side wall of annular step one 31, and positioning ring 61 is arranged on the outer wall of main body 1, and this positioning ring 61 is embedded in the positioning groove, and cap body 3b is preliminarily fixed on the main body 1, and cap body one 3a It is fixed on the main body 1 by threaded connection or welding so that the cap body 2 3b is fixed more firmly. The second cap body 3b is mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com