Blade of vertical axis wind turbine

A wind power generator, vertical axis technology, applied to wind power generators, wind power generators at right angles to the wind direction, engines, etc., can solve the problem of closed airfoil blades with small sweeping area, slow start speed, and affecting the start wind speed of the wind rotor And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

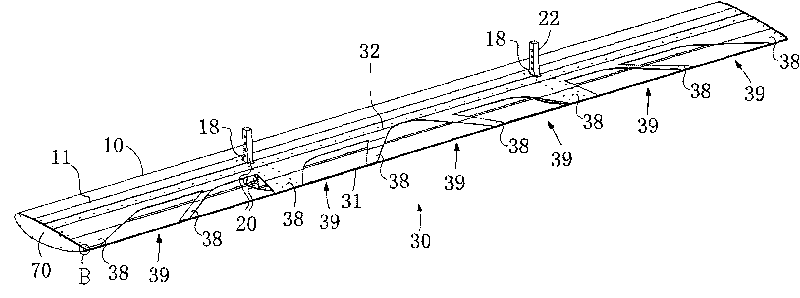

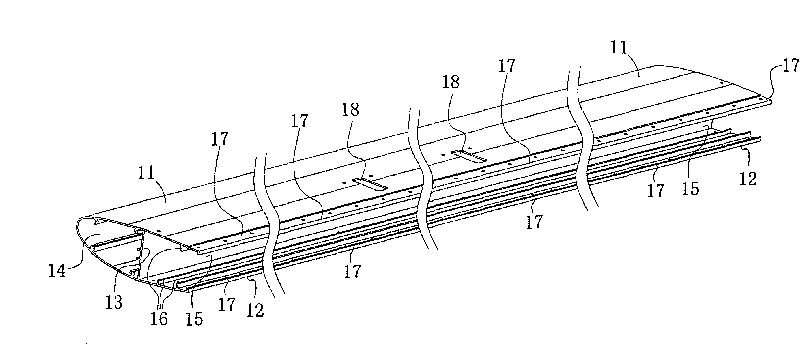

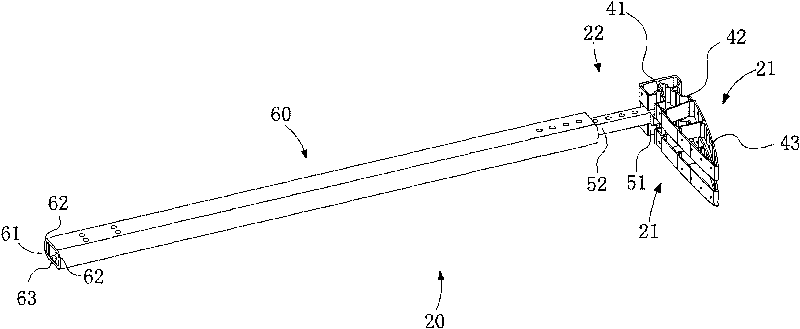

[0028] Such as Figure 1-9 Shown: a blade of a vertical axis wind power generator, which includes a shell unit 10, a blade support unit 20 and a wind hunting unit 30, wherein the shell unit 10 includes a first shell baffle 11, a second shell baffle Plate 12 and reinforcement baffle 13.

[0029] Such as figure 1 , 2 As shown: one side of the first casing baffle 11 is fixedly connected to one side of the second casing baffle 12, and the reinforcing baffle 13 is fixedly connected to the first casing baffle 11 and the second casing Between the baffles 12, a cavity 14 and a snap-in groove 15 are formed. The cavity 14 is arranged near the side where the first housing baffle 11 and the second housing baffle 12 are connected, and the cavity The two ends of body 14 are connected.

[0030] The clamping groove body 15 is arranged on the other side of the cavity body 14, the groove wall of the clamping groove body 15 is formed by the first housing baffle plate 11 and the second housin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com