Method for treating leachate in refuse landfill site

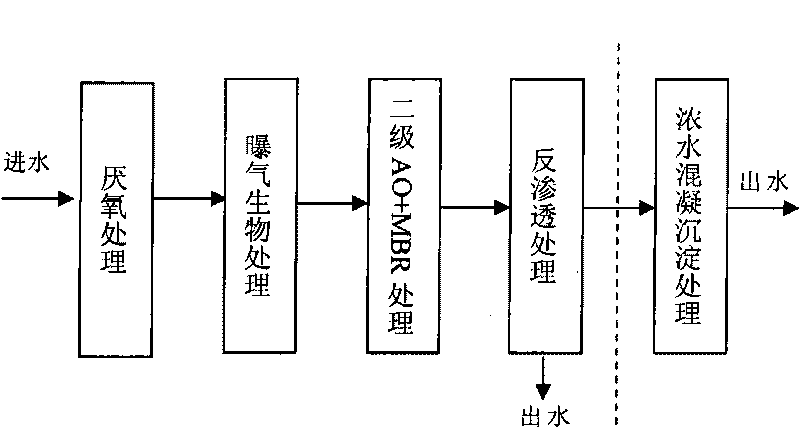

A technology of landfill leachate and a treatment method, which is applied to the treatment field of landfill leachate in sanitary landfills, can solve the problems of thorough decomposition and removal of pollutants, the problems of ammonia nitrogen and total nitrogen treatment are not considered, and it is difficult to achieve, and the operation is achieved. The effect of low cost, stable operation and complete process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

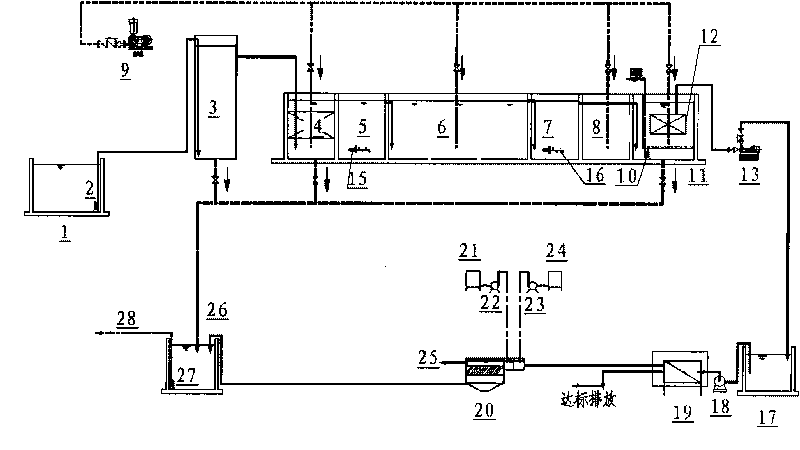

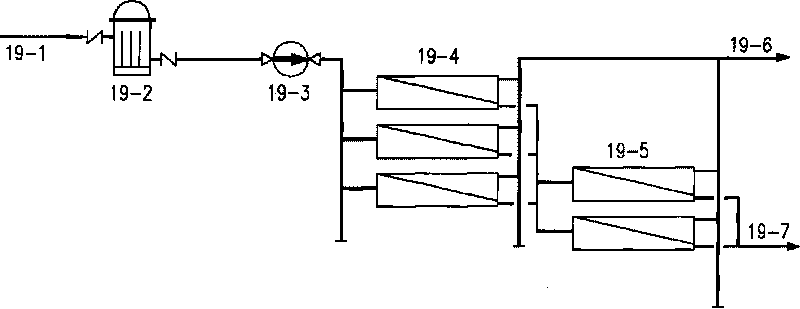

Method used

Image

Examples

Embodiment 1

[0056] A landfill leachate COD 8000-12000mg / L, BOD 2000-3000mg / L, ammonia nitrogen 1600-2400mg / L. The water quality is characterized by high concentration of organic matter, poor biodegradability of wastewater, and BOD / COD=0.2.

[0057] Anaerobic reactor operating load 5kgCOD / m 3 .d (the unit d here means "day", the same below), the operating temperature is controlled at 20-35 degrees Celsius, the pH is controlled below 7.0, and the COD removal rate is 30-40%. Anaerobic effluent COD is 5600-7200mg / L. This unit has no removal rate for ammonia nitrogen. The ammonia nitrogen in the anaerobic effluent is 1600-2400mg / L, and the total nitrogen is 1600-2400mg / L. The total nitrogen in the anaerobic effluent mainly exists in the form of ammonia nitrogen.

[0058] The BAF (biological aerated filter) unit acts as a pretreatment for ammonia nitrogen, and also has a high removal rate for total nitrogen and COD. The BAF unit is filled with polyurethane-based filler, the filler residence...

Embodiment 2

[0062] A landfill leachate COD 2000-4000mg / L, BOD 1000-2000mg / L, ammonia nitrogen 500-800mg / L. The water quality is characterized by fresh leachate, low concentration of organic matter, good biodegradability of wastewater, BOD / COD=0.5.

[0063] Anaerobic reactor operating load 1kgCOD / m 3 .d (the unit d here means "day", the same below), the operating temperature is controlled at 20-35 degrees Celsius, the pH is controlled below 7.0, and the COD removal rate is 20-30%. Anaerobic effluent COD is 1600-2800mg / L. This unit has no removal rate for ammonia nitrogen. The ammonia nitrogen in the anaerobic effluent is 500-800mg / L, and the total nitrogen is 500-800mg / L. The total nitrogen in the anaerobic effluent mainly exists in the form of ammonia nitrogen.

[0064]The BAF (biological aerated filter) unit has a removal rate of ammonia nitrogen of 40-50%, effluent ammonia nitrogen of 300-400mg / L, total nitrogen removal rate of 30-40%, and effluent total nitrogen of 350-480mg / L. The...

Embodiment 3

[0068] A landfill leachate COD 2000-4000mg / L, BOD 200-400mg / L, ammonia nitrogen 1000-1500mg / L. The water quality is characterized by old landfill leachate, with low concentration of organic matter, but high ammonia nitrogen, poor biodegradability of wastewater, BOD / COD=0.1.

[0069] Anaerobic reactor operating load 1kgCOD / m 3 .d (the unit d here means "day", the same below), the operating temperature is controlled at 20-35 degrees Celsius, the pH is controlled below 7.0, and the COD removal rate drops to 10-15%. Anaerobic effluent COD is 1800-3400mg / L. This unit has no removal rate for ammonia nitrogen. The ammonia nitrogen in the anaerobic effluent is 1000-1500mg / L, and the total nitrogen is 1000-1500mg / L. The total nitrogen in the anaerobic effluent mainly exists in the form of ammonia nitrogen.

[0070] The BAF (biological aerated filter) unit has a removal rate of ammonia nitrogen of 60-70%, 400-450mg / L of ammonia nitrogen in the effluent, 40-50% of the total nitrogen r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com