Fully automatic soymilk machine

A soymilk machine, a fully automatic technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of deterioration of beans, hindering reservation pulping, and inability to automatically increase ingredients, etc., and achieves convenient and easy use and cleaning. Simple and smooth structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

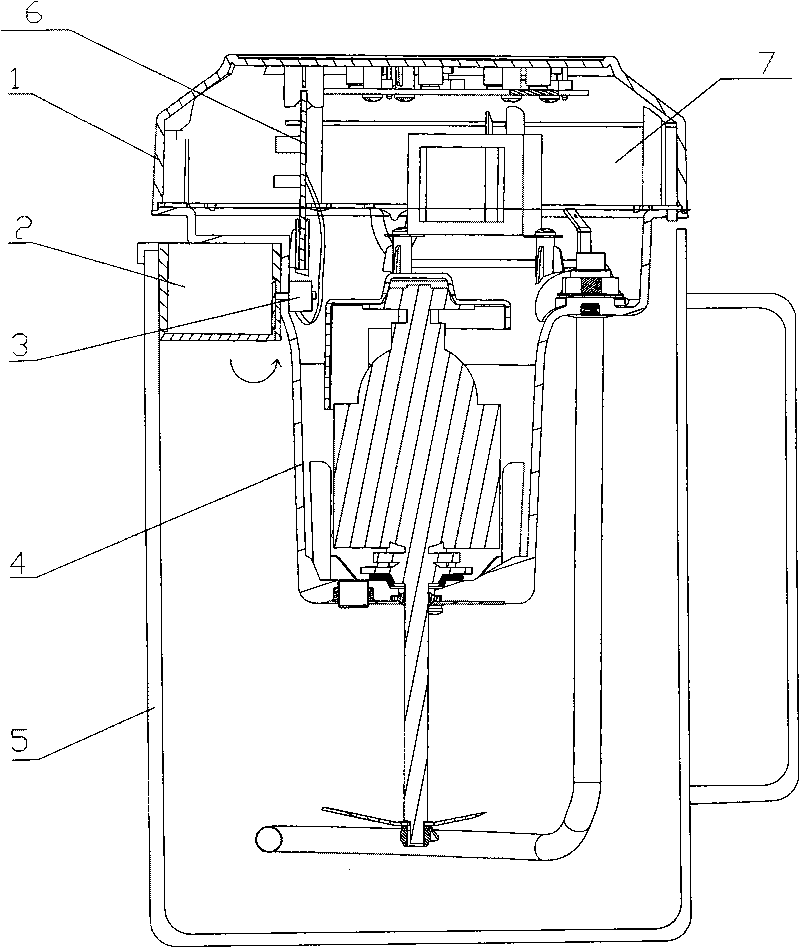

[0011] Embodiment 1, see attached Figure 1~4 .

[0012] The fully automatic soybean milk machine shown in the figure includes a cup body 5, a machine head 7 and a circuit control board 6 installed in the inner cavity of the machine head. The machine head 7 is rested on the mouth edge of the cup body 5. The cover 1 and the lower cover 4 which is closed with the upper cover are composed, and a motor is also built in the lower cover. In this embodiment, a material storage box 2 is built in the cup body, and the material storage box is sandwiched between the inner wall of the cup and the outer wall of the lower cover, and its shape matches the inner wall of the cup and the outer wall of the lower cover. During installation, this material storage box hangs on the rim of the cup body by means of the hook 26 on the box edge. The material storage box is provided with a box-opening bottom locking device that matches the electromagnetic valve trigger switch 3 in the machine head, tha...

Embodiment 2

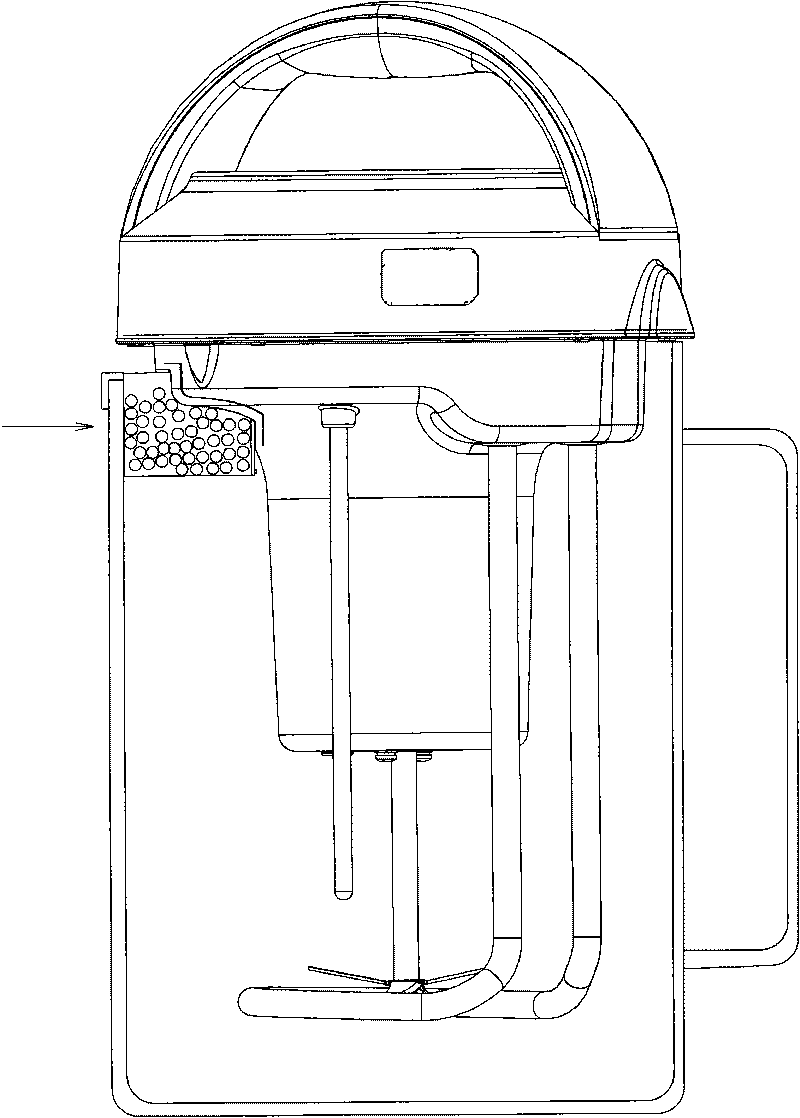

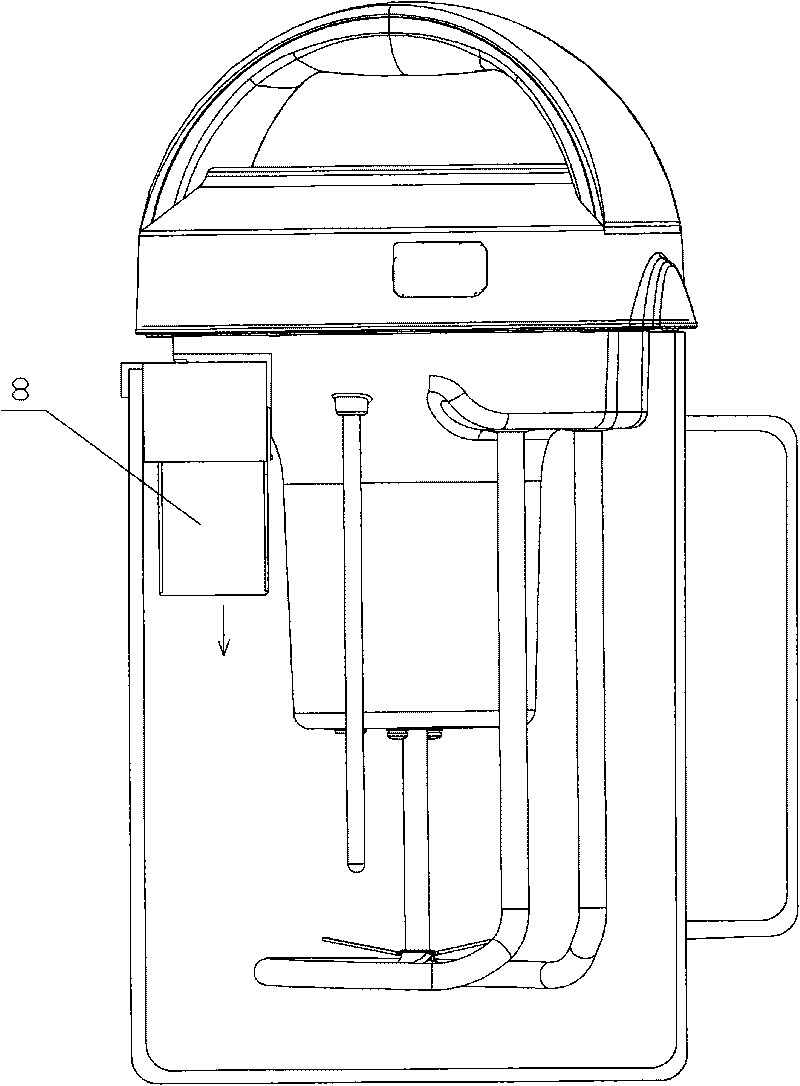

[0014] Embodiment 2, see attached Figure 5-8 .

[0015] The fully automatic soybean milk machine shown in the figure includes a cup body 5, a machine head 7 and a circuit control board 6 installed in the inner cavity of the machine head. The machine head 7 is rested on the mouth edge of the cup body 5. The cover 1 and the lower cover 4 which is closed with the upper cover are composed, and a motor is also built in the lower cover. In this embodiment, a material storage box 2 is also arranged on the wall of the cup body. The material storage box relies on the wall of the cup and is stuck or inserted into a through hole or a groove on the wall of the cup. The material storage box is wedge-shaped and the front end of the wedge-shaped box is a discharge port 26 located in the cup body, and a feeding device is provided at the discharge port. The rear end of the wedge-shaped box is located outside the cup body and has a feed port on the upper surface 27 and the switch of controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com