Metal armoured optical cable

A technology of metal armor and optical fiber wire, applied in the direction of fiber mechanical structure, etc., to achieve the effect of cost reduction, reasonable structure and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to fully understand the technical content of the present invention, the technical solution of the present invention will be further introduced and illustrated below in conjunction with specific embodiments.

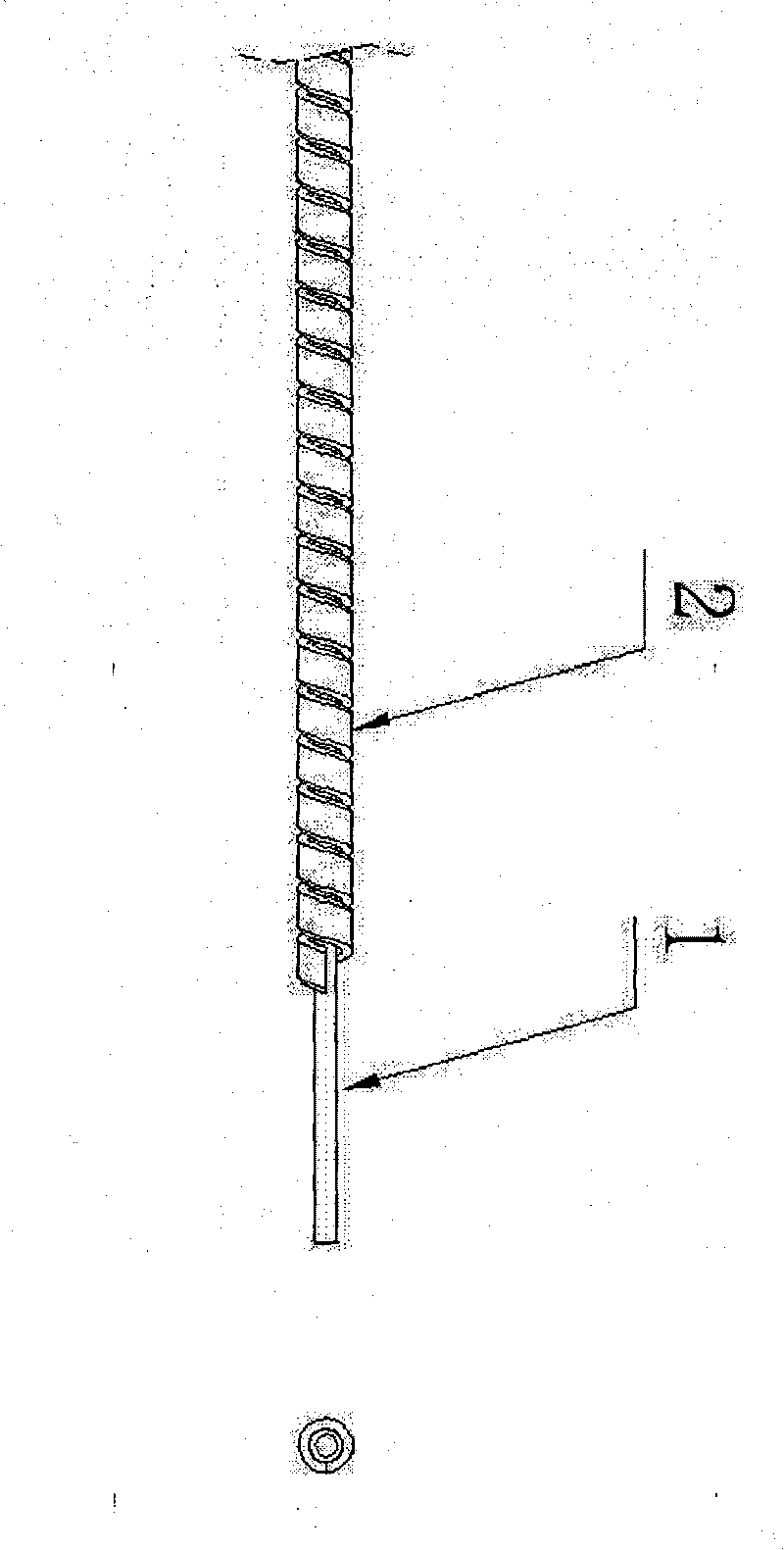

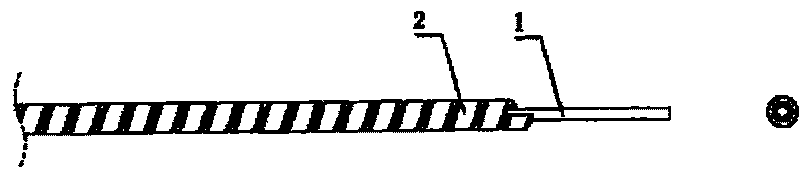

[0019] Metal armored optical fiber cable of the present invention, such as figure 1 As shown, a metal sheath 2 is provided on the outside of the bare optical fiber 1, and the metal sheath 2 is in a spiral shape and wraps the bare optical fiber 1 inside in a surrounding manner.

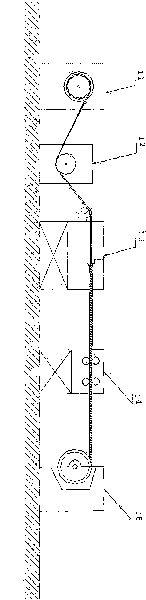

[0020] And this metal armor 2 is installed on the cladding process on the bare optical fiber 1, such as figure 2 The embodiment of the present invention illustrates that the bare optical fiber 1 is placed in the bare optical fiber pay-off mechanism 11, so that the bare optical fiber 1 can be rolled out gradually, and the bare optical fiber 1 enters a fiber pay-off tensioner 12, so that the bare optical fiber 1 is subjected to an appropriate tension. Tension pulls, and then enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com