Full-automatic vacuum degasser and degassing method thereof

A vacuum degassing device, fully automatic technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of high and low degassing efficiency, irregular data, and affecting the reliability of analysis results, etc., to achieve degassing The gas efficiency is stable, the accuracy is guaranteed, and the effect of controllable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

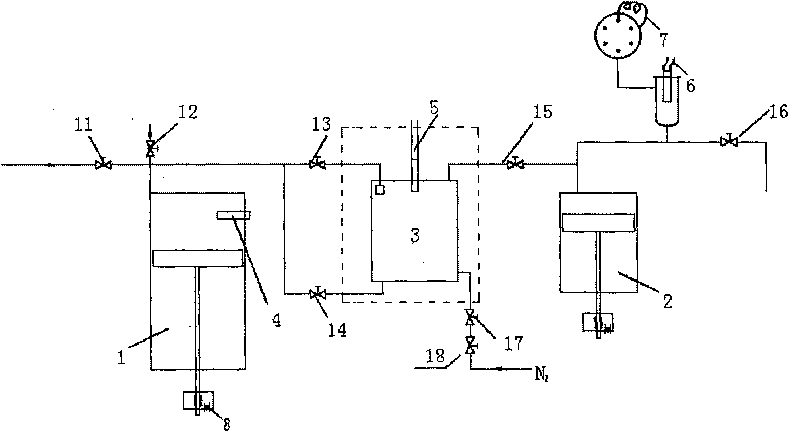

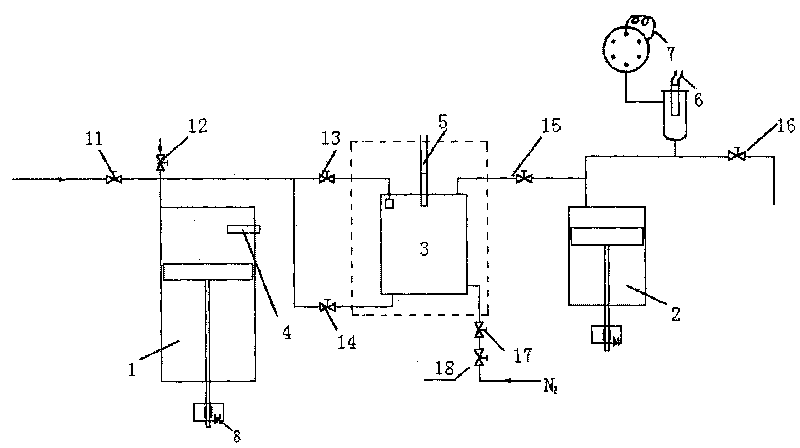

[0014] The present invention will be further described below in conjunction with the accompanying drawings. figure 1 It is a structural schematic diagram of the automatic vacuum degassing device of the present invention.

[0015] The present invention provides a fully automatic vacuum degassing device, comprising a first cylinder 1, a second cylinder 2 and a degassing chamber 3, characterized in that: the first cylinder 1 is connected to an oil inlet pipe, and a first valve is arranged on the oil inlet pipe 11. The first cylinder 1 is connected to the oil discharge pipe, the oil discharge pipe is provided with a second valve 12, the first cylinder 1 is connected to the atomizing nozzle of the degassing chamber 3 through the third valve 13, the first cylinder The oil discharge port of 1 communicates with the bottom oil discharge port of the degassing chamber 3 through the fourth valve 14, and the degassing chamber 3 is connected with the second cylinder 2 through the fifth valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com