On-line detection device and on-line detection method for wheel rim of train wheel

A detection method and technology for train wheels, which are applied to the analysis of solids by using sonic/ultrasonic/infrasonic waves, can solve the problems such as the inability to realize comprehensive detection of wheel rims, and the detection range being limited to a certain range under the tread of the wheel rim. Simple, guaranteed bearing capacity, high-speed detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

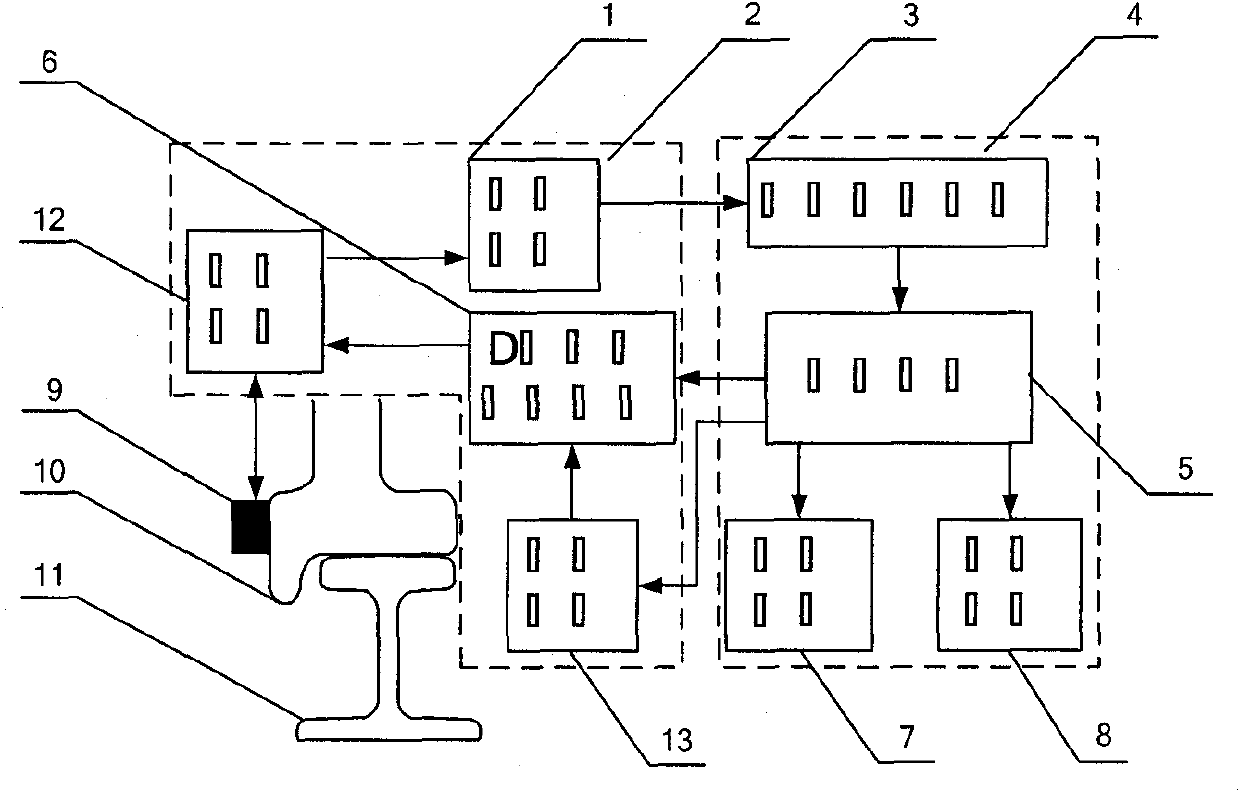

[0026] Embodiment 1, combining figure 1 , figure 2 , image 3 , the present invention is an on-line detection device for train wheel tires, which is composed of an electromagnetic ultrasonic probe array (9), a front box (2) and a control processing unit (4), and the electromagnetic ultrasonic probe array (9) passes through a shielded wire Connect the front box (2), and the front box is connected to the control processing unit (4) through a shielded wire.

[0027] The present invention also has the following technical characteristics:

[0028] The front box includes a power amplifying circuit, a receiving circuit, a boost circuit and a transfer switch, the transfer switch is respectively connected to the receiving circuit and the power amplifying circuit, and the power amplifying circuit is connected to the boosting circuit.

[0029] The control processing unit includes a data acquisition circuit, a microprocessor, a storage circuit and a display circuit, the data acquisiti...

Embodiment 2

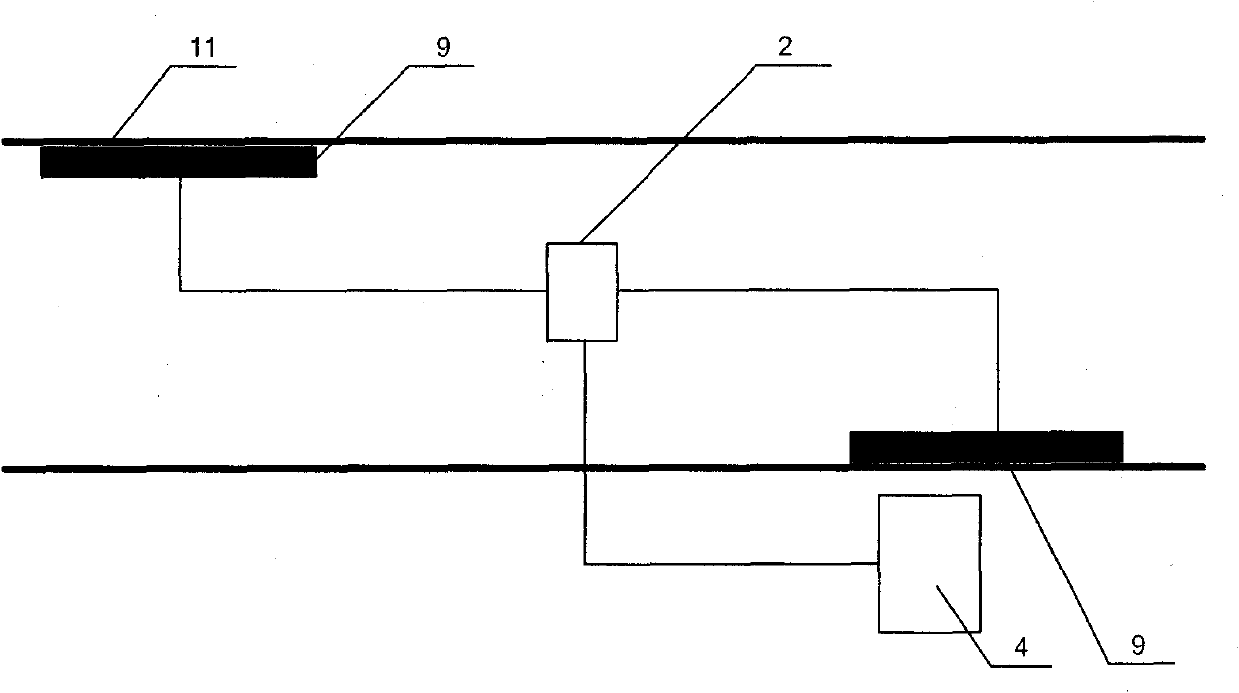

[0041] Example 2, combined with figure 2 , image 3 , the present invention is an on-line detection device and method for train wheel tires, wherein the ultrasonic detection probe is an electromagnetic ultrasonic probe with integrated functions of sending and receiving. The working process of the detection device is as follows: the microprocessor (4) sends a control signal to the class D power amplifier circuit (6), and the class D power amplifier circuit (6) drives the electromagnetic ultrasonic probe to send out vertical incident body waves. The vertically incident body wave propagates in the wheel rim with a propagation speed of about 3000m / s. When it encounters a defect, part of the energy will be emitted, and the rest of the energy will continue to propagate and reflect when it encounters the end surface. The electromagnetic ultrasonic probe receives the reflected echo of the defect and the reflected echo of the end face. The propagation path of ultrasonic waves in the...

Embodiment 3

[0042] Example 3, combined with figure 2 , image 3 , Figure 4 , the present invention is an on-line detection device and method for train wheel tires, each of the probes can transmit and receive ultrasonic waves, and before the detection, the electromagnetic ultrasonic probes are first installed on the rails, and the defects are detected by using the ultrasonic probes. The wheel rim is detected, and the ultrasonic amplitude received by the ultrasonic probe is recorded at this time. In actual detection, such as Figure 4 As shown, if there is a defect inside the wheel rim, when the ultrasonic wave encounters the defect, part of the energy will be reflected, and the ultrasonic probe will receive the echo signal reflected by the defect, while the remaining energy will continue to propagate, and it will be reflected when it encounters the end face. At the same time, the reflected echo of the end face can be received. The defect size and type can be quantified by measuring t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com