Longitudinal calibration method in mounting shaft device

A technology of equipment installation and calibration method, which is applied in the field of longitudinal calibration method, can solve the problems of large installation error, difficult operation, complicated process, etc., and achieve the effects of high installation accuracy, reduced labor intensity, and short installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

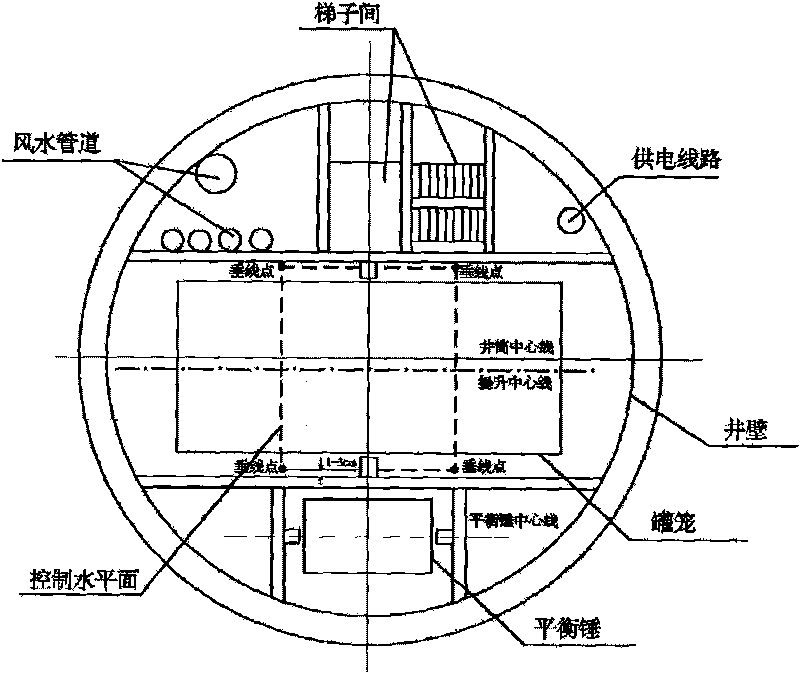

[0030] The shaft is 580 meters long, and the main equipment of the shaft is single cage, counterweight (operating equipment), 7 beams (2 main beams, 5 auxiliary beams), 4 vertical beams, ladder room, wind and water pipes, cables (fixed facilities) . The longitudinal calibration method in the installation of shaft equipment, including the arrangement of the measuring vertical line, the determination of the horizontal installation surface and the setting out of the installation position of the horizontal equipment, wherein:

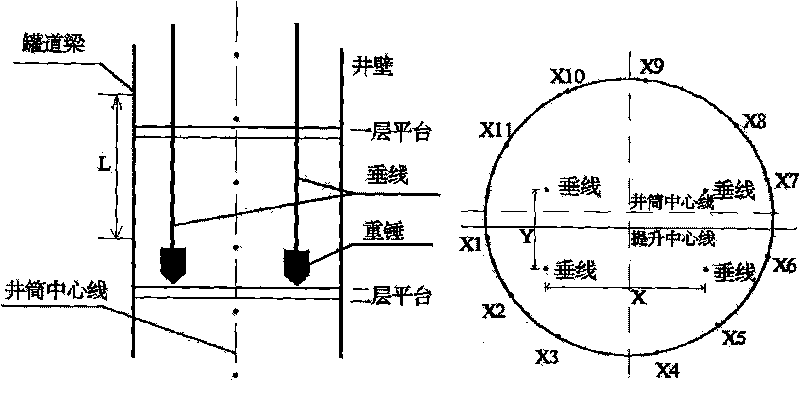

[0031] 1) The layout of the measuring vertical line is as follows: first determine the position of the vertical line: see figure 1 , design 4 parallel vertical lines along the two main beams, the vertical line is located between the two beams, and the vertical distance between the adjacent beams is 3cm; then stake out the vertical lines and wellbore equipment on the temporarily closed well surface sealing plate The plane position and the installation desi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com