Impulse electromagnet for electromagnetic acoustic transducer

A pulsed electromagnet and electromagnetic ultrasonic technology, applied in the field of pulsed electromagnets, can solve the problems of inconvenience, reduced energy conversion efficiency, wear, etc., and achieve the effects of convenient volume change, low power consumption, and high design flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

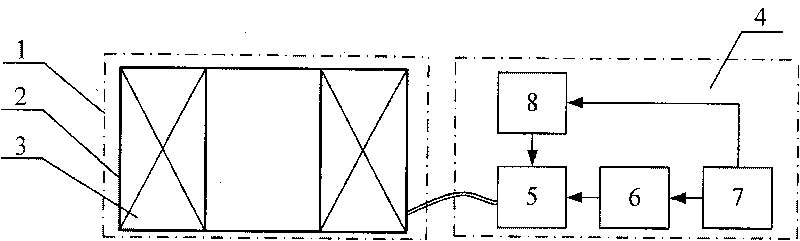

[0018] Embodiment 1, combining figure 1 , the present invention is a kind of pulse electromagnet that is used for electromagnetic ultrasonic transducer, and it is made up of pulse electromagnet (1) and pulse electromagnet driving circuit (4), and pulse electromagnet driving circuit (4) connects pulse electromagnet (1).

[0019] The present invention also has the following technical characteristics:

[0020] The pulse electromagnet (1) includes a skeleton (2) and a coil (3), and the coil (3) is wound on the skeleton (2).

[0021] Described pulse electromagnet drive circuit (4) comprises power pulse shaping circuit (5), power drive circuit (6), control host (7) and booster circuit (8), and control host (7) connects power drive circuit ( 6) and the boost circuit (8), the power drive circuit (6) is connected to the power pulse shaping circuit (5), and the power pulse shaping circuit (5) is connected to the boost circuit (8).

Embodiment 2

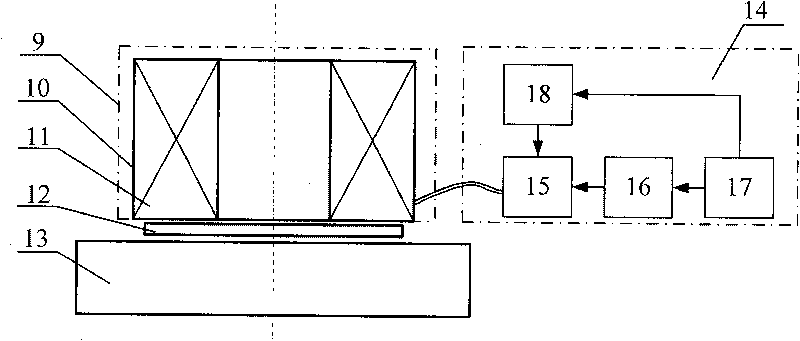

[0022] Example 2, combined with figure 2 , an electromagnetic ultrasonic transducer using a pulsed electromagnet, which is composed of a pulsed electromagnet (9), a pulsed electromagnet drive circuit (14), an electromagnetic ultrasonic coil (12), and a test piece (13). The electromagnetic ultrasonic coil (12) is placed on the test piece (13), the pulse electromagnet (9) is placed on the electromagnetic ultrasonic coil (12), and the pulse electromagnet drive circuit (14) is connected to the pulse electromagnet (9). The pulse electromagnet (9) consists of a skeleton (10) and a coil (11). The coil (11) is wound on the skeleton (10). The pulse electromagnet drive circuit (14) is composed of a power pulse shaping circuit (15), a power drive circuit (16), a control host (17), and a boost circuit (18). Wherein the control host (17) is connected to the power drive circuit (16), the power drive circuit (16) is connected to the power pulse shaping circuit (15), the control host (17) ...

Embodiment 3

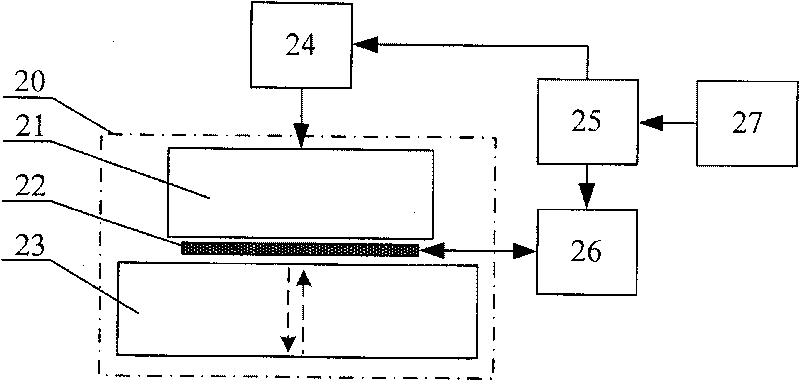

[0024] Example 3, combined with image 3 , Figure 4 , an electromagnetic ultrasonic thickness measuring device using a pulsed electromagnet is an electromagnetic ultrasonic transducer (20) composed of a pulsed electromagnet (21), an electromagnetic ultrasonic coil (22), and a test piece (23), and a pulsed electromagnet drive circuit (24), control circuit (25), transmitting and receiving circuit (26), main frame (27) forms. Figure 4 Among them, the pulse electromagnet coil (28), the electromagnetic ultrasonic coil (29), the eddy current (30), the magnetic force line (31), and the test piece (32). This figure is a schematic diagram of the magnetic field generated by the pulse electromagnet in the non-ferromagnetic material.

[0025] When the device starts to work, the control signal is given by the host to the control circuit, and the control circuit controls the pulse electromagnet drive circuit to generate a large current in the pulse electromagnet coil, which instantly gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com