Cam pressing type tee ball valve

A three-way ball valve, press-type technology, applied in multi-way valves, valve devices, cocks including cut-off devices, etc., can solve problems such as leakage of three-way ball valves, and achieve the effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

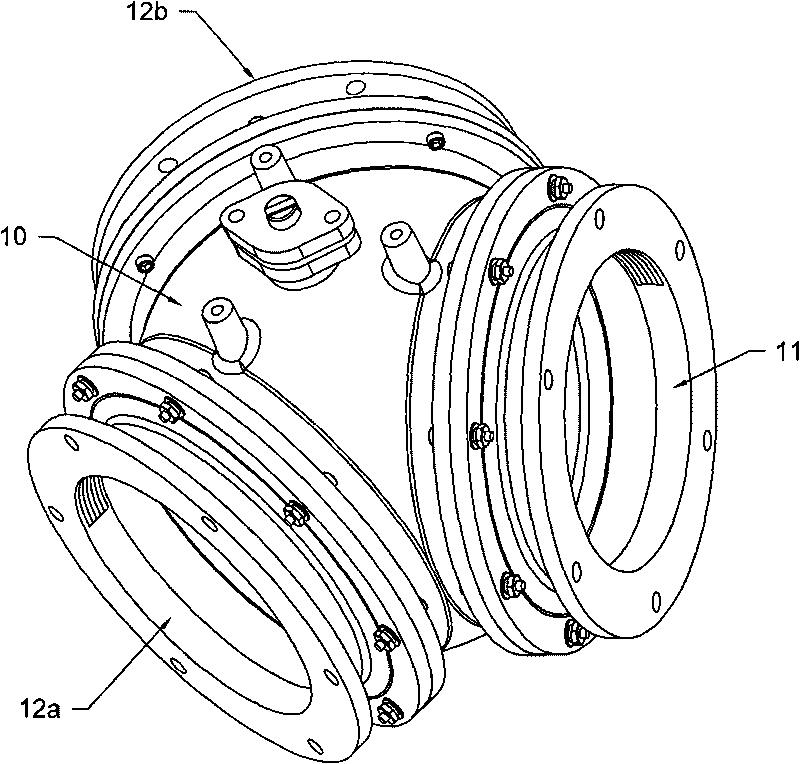

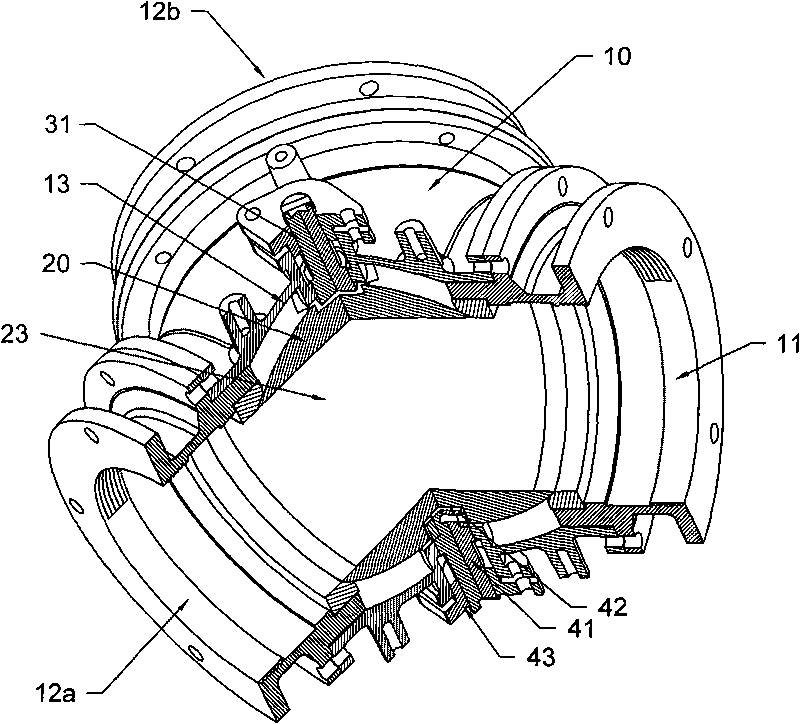

[0024] Such as Figures 1 to 5 As shown, in the preferred embodiment of the cam compression type three-way ball valve of the present invention, it includes a valve body 10, a spherical valve core 20, a rotation driving mechanism, and a compression mechanism. Among them, the valve body 10 is provided with an inlet 11 and two outlets 12a, 12b, between the inlet 11 and the outlets 12a, 12b is a hollow valve cavity 13, and the valve cavity 13 is set in a spherical shape matching the valve core 20. A communication passage 23 is provided in the valve core 20, and the communication passage 23 can communicate the inlet 11 with an outlet 12a or 12b. The rotation drive mechanism includes a drive shaft 31 and a power source (not shown in the figure), and the power source may be a power device such as a motor that can make the drive shaft 31 rotate as required. The drive shaft 31 is rotatably arranged on the valve body 10, one end of which is connected to the valve core 20, and the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com