Method for preparing naringin

A technology of naringin and pore adsorption, applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems of low naringin content, unfavorable large-scale production operations, serious pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

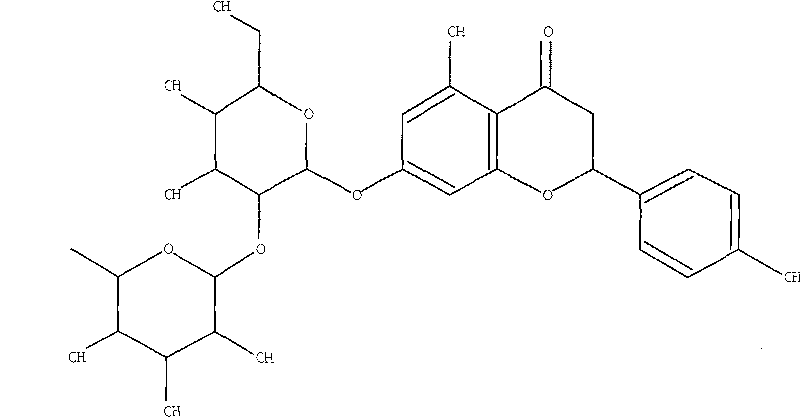

Image

Examples

Embodiment 1

[0017] Take 10Kg of Huajuhong coarse powder, add 8 times the volume of water, soak at 30°C for 8 hours, press filter, take the filtrate, add CaCl 2 , stir evenly, place overnight, filter, take the filtrate, add concentrated ammonia water to adjust pH 7-8, absorb through a macroporous adsorption resin column, wash with water to remove impurities, 50% ethanol for elution, and collect 3 times the column volume of the eluate , recover ethanol under reduced pressure and concentrate, refrigerate, precipitate crystals, separate crystals, add absolute ethanol for recrystallization, separate, wash and dry to obtain naringin 88.2g, which is detected by HPLC with a purity of 98.2%.

Embodiment 2

[0019] Take 10Kg of Huajuhong coarse powder, add water 12 times the volume of its weight, soak at 80°C for 24 hours, press filter, take the filtrate, add CaCl 2 , stir evenly, place overnight, filter, take the filtrate, add concentrated ammonia water to adjust the pH7-8, adsorb through a macroporous adsorption resin column, wash with water to remove impurities, 90% ethanol for elution, and collect 8 times the column volume of the eluate , recover ethanol under reduced pressure and concentrate, refrigerate, precipitate crystals, separate crystals, add absolute ethanol for recrystallization, separate, wash and dry to obtain 103.9 g of naringin, which is detected by HPLC with a purity of 98.1%.

Embodiment 3

[0021] Take 10Kg of Huajuhong coarse powder, add water 10 times the volume of its weight, soak at 60°C for 12 hours, press filter, take the filtrate, add CaCl 2 , stir evenly, place overnight, filter, take the filtrate, add concentrated ammonia water to adjust pH 7-8, absorb through D101 macroporous adsorption resin column, wash with water to remove impurities, 75% ethanol for elution, collect 5 times the amount of column volume for elution Liquid, recovered ethanol under reduced pressure and concentrated, refrigerated, precipitated crystals, separated crystals, added absolute ethanol for recrystallization, separated, washed and dried to obtain 118.9 g of naringin, which was detected by HPLC with a purity of 99.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com