Front defrosting grid for automobile

A grille and automobile technology, applied in vehicle maintenance, vehicle cleaning, transportation and packaging, etc., can solve the problems of reducing the air outlet area, limited space for the front defrost tuyere, shortening the length of the front defrost tuyere, etc. Ensure driving safety and improve the effect of excessive airflow concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

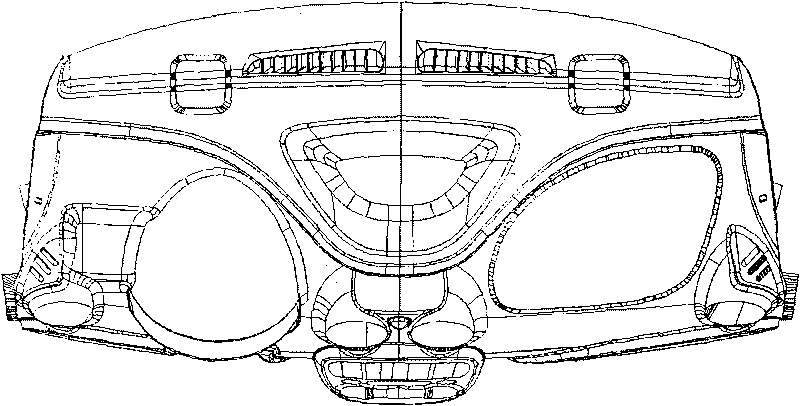

[0016] see figure 1 , the air outlet length of the front defrosting grille 5 is less than half of the length of the instrument panel 6, and is arranged in the middle of the instrument panel 6.

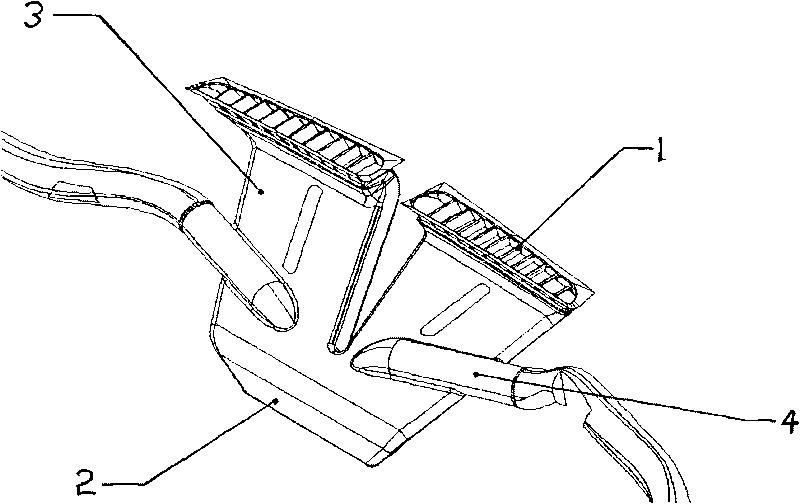

[0017] see figure 2 The structure of the front defrosting grille 5 includes a central air duct 3 and a front air outlet grille 1, an air inlet 2 is arranged at the bottom of the central air duct 3, a side defrosting air duct 4 is connected to the middle, and a side defrosting air duct 4 is connected to the top end of the central air duct 3. There are two groups of front outlet grilles 1 symmetrically arranged left and right.

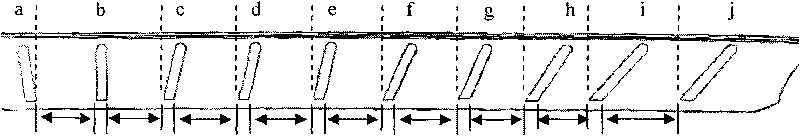

[0018] see image 3 , this is a partially enlarged rendering of a group of front air outlet grilles 1. In the figure, the airflow pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com