Intelligent forest fire extinguishing bomb

A forest and fire extinguishing agent technology, applied in warheads, ammunition, fire rescue, etc., can solve problems such as poor fire extinguishing effect and inability to fire extinguishing operations, and achieve the effect of efficient and rapid fire extinguishing and improved utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

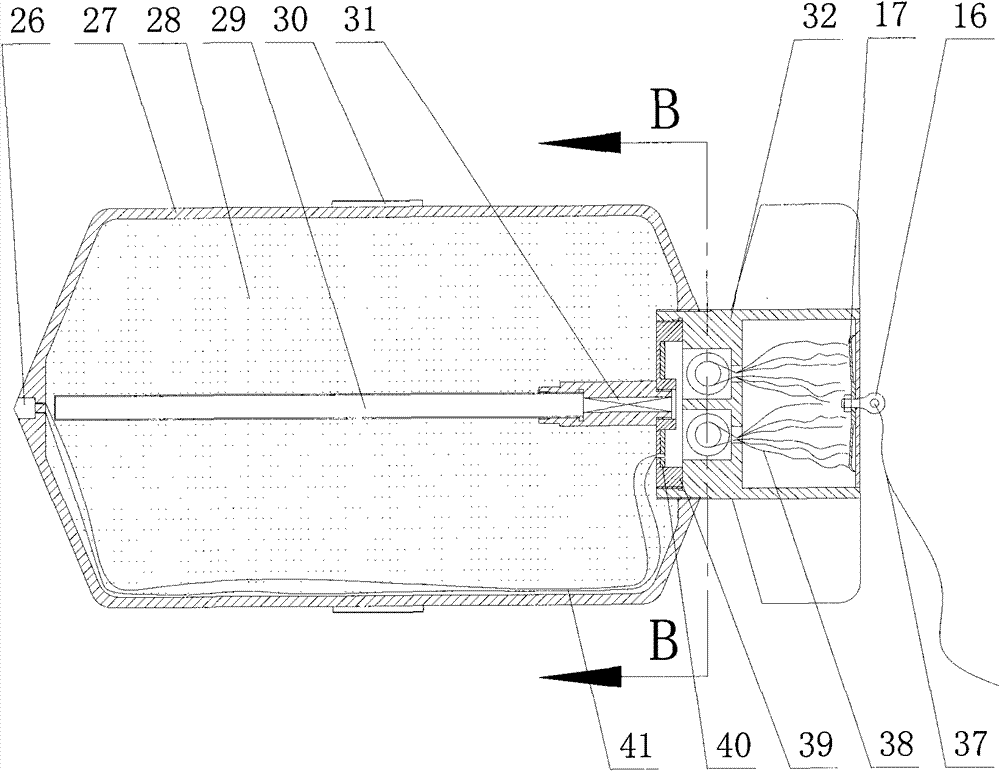

[0018] Example 1: Combining figure 1 , the fire extinguishing bomb is made up of the fire extinguishing agent chamber at the front and the umbrella chamber at the rear, the detonating explosive 29 is located at the center of the fire extinguishing agent chamber, and is connected horizontally with the detonating detonator 31, and the fire extinguishing agent 28 is located around the detonating explosive 29 and surrounded by the shell 27, the control Circuit 40 is positioned on connecting ring 39, and connecting ring 39 links to each other with priming detonator 29 and umbrella storehouse body 32 by threaded connection, and temperature sensor 26 is positioned at cartridge case 27 front ends, and umbrella storehouse links to each other with fire extinguishing agent storehouse by threaded connection, and parachute throwing device is connected by hanger. cable 37, hook 16, spring leaf 17 and rear end cover 14, the hook 16 is threadedly connected with the rear end cover 14 and spring...

Embodiment 2

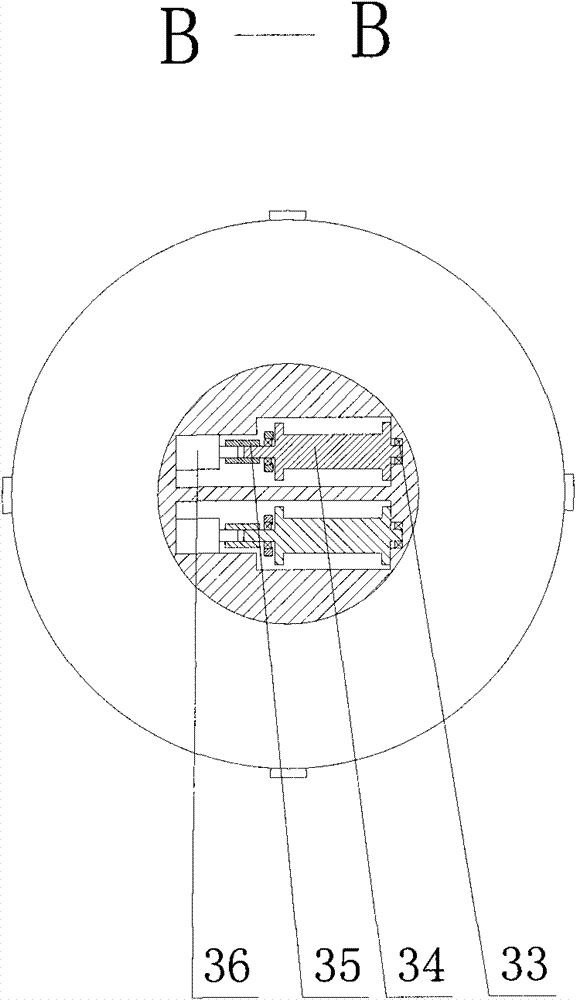

[0019] Embodiment 2: Combination figure 1 , the following device is installed in the fire extinguishing bomb described in Embodiment 1. The thermal sensors 30 are arranged in a ring on the cylinder of the bullet case 27, the sensor is connected to the bullet control circuit 40 through a wire 41, and the parachute power adjustment device is located at the bottom of the parachute chamber body , driven by two parallel motors 36 through coupling 35 to form the reel 34, the parachute umbrella rope is positioned in the guide groove of the reel 34, the reel 34 links to each other with the umbrella bin body 32 by the bearing 33. During the descending process of the fire extinguishing bullet, the thermal sensor 30 sends the signal to the control circuit 40 by sensing the temperature difference around the bullet. Pull the parachute cord to adjust the falling trajectory of the bullet so that it can fall directly above the fire scene, and complete the fire extinguishing operation more acc...

Embodiment 3

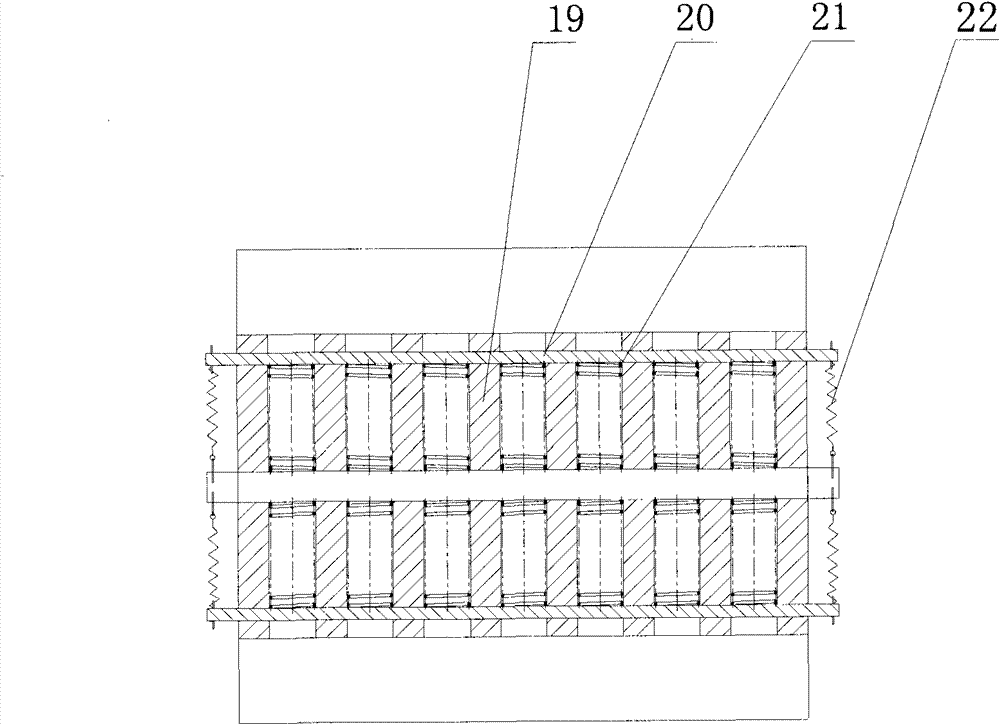

[0020] Example Three: Combining figure 2 and image 3 , on the basis of the original fire extinguishing bomb, the fire extinguishing bomb is used as the bullet 6 and the shell and its ejection device are designed to form a parent bullet. The mother bomb is composed of a front magazine storage chamber and a rear umbrella warehouse, the two are connected by a central axis 18 located in the center of the magazine storage chamber, and the magazine storage chamber is mainly composed of a cutting cable 1, an electric detonator 2, a bayonet pin 3, and a protective cover 4. The ejection device 5, the bullet 6, the annular clamping plate 7, the mother bullet control circuit 8, the mother bullet case 9, and the spring 10 are composed. The cutting cable 1 is located in the ring-shaped slots at the front end and the rear end of the mother projectile case 9 and is connected with the electric detonator. 2 are connected, the protective cover 4 is located at the front end of the storage mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com