Winding device of activated carbon fiber filter

A technology of activated carbon fiber and winding device, which is applied in the direction of fixed filter element filter, filtration separation, ion exchange treatment device, etc., can solve the problems of low winding efficiency, affecting adsorption efficiency, large difference in tightness, etc., and achieve reasonable structure, Improve labor efficiency and reduce noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

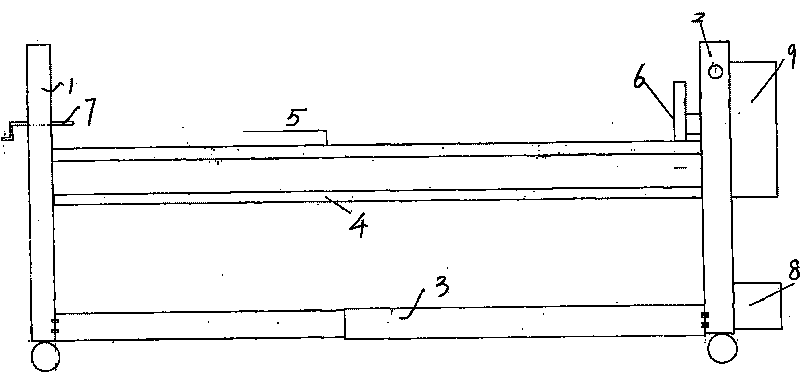

[0010] An activated carbon fiber filter winding device, including left and right frame bodies 1 and 2, the left and right frame bodies are connected by brackets 3, and supporting arms for supporting activated carbon fiber materials are installed between the left and right frame bodies 4 and the tension tube 5 for adjusting the tension of the activated carbon fiber material. One side of the left and right frame bodies is equipped with a turntable 6 that drives the filter element to rotate, and the other side of the left and right frame bodies is equipped with a device that tightens the filter element. Rocker adjustable thimble 7.

[0011] The bracket is in a length-adjustable form. The turntable is connected with the variable frequency motor 8 driving devices. Also have control box 9 among the figure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com