Cyclone dust collecting device of dust collector

A cyclone dust removal and vacuum cleaner technology, which is applied in the direction of cyclone devices, suction filters, and devices whose axial direction can be reversed, can solve the problems of cumbersome operation, simplify cleaning operations, improve dust removal efficiency, and improve dust removal effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

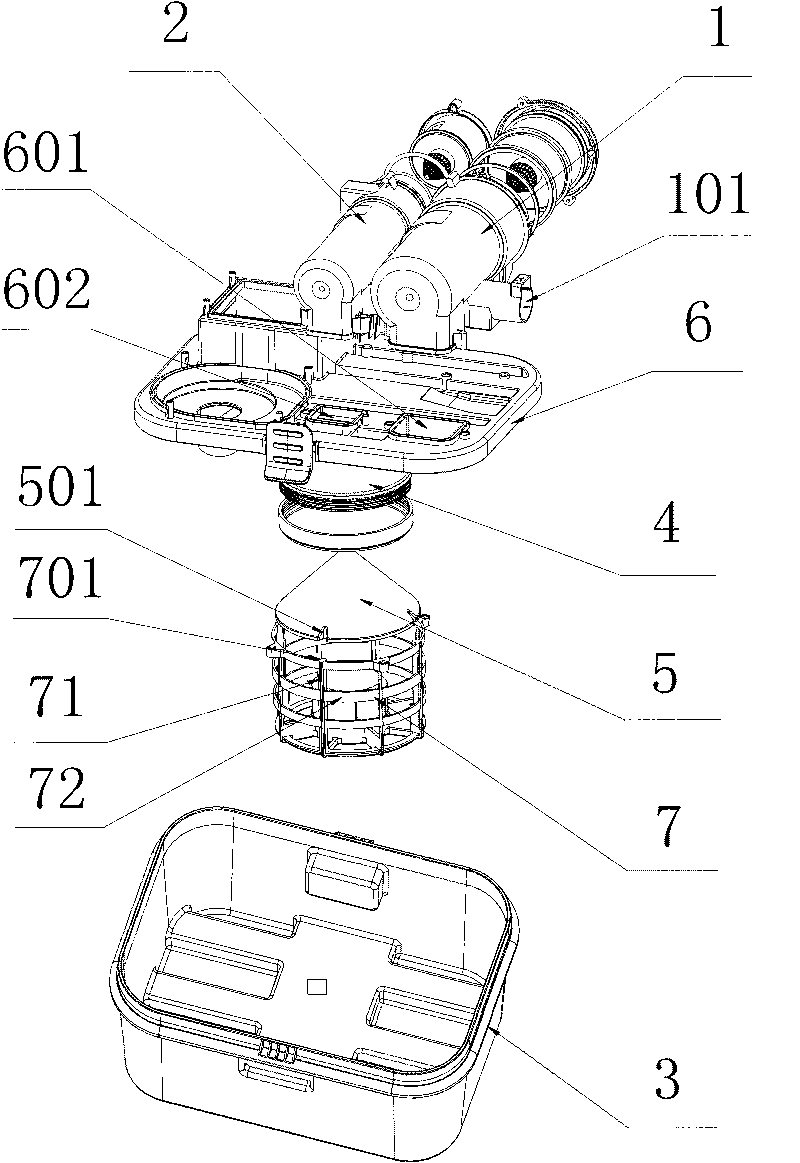

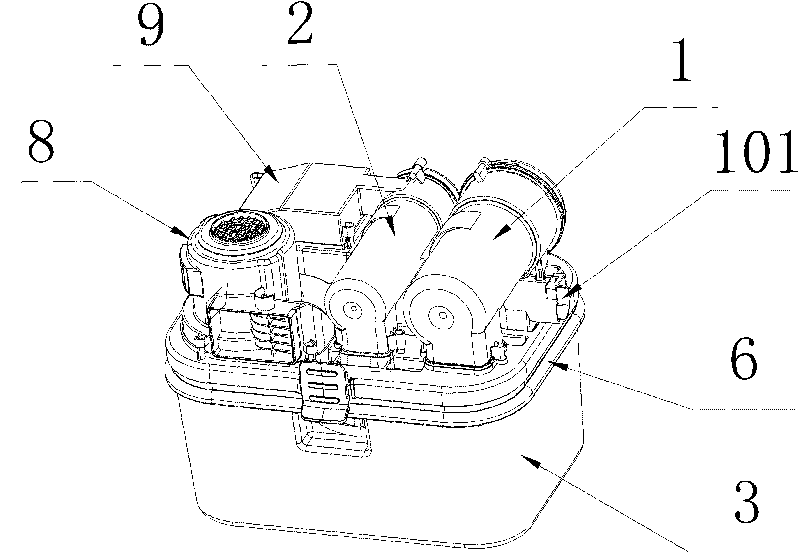

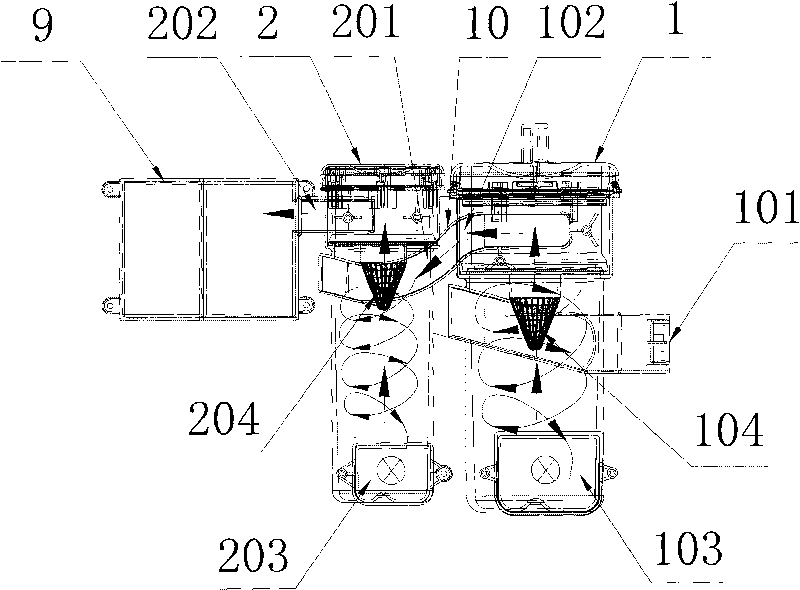

[0029] Example: first combine figure 1 , figure 2 , image 3 As shown, in the vacuum cleaner cyclone dust removal device provided in this embodiment, the first-stage cyclone separator 1 and the second-stage cyclone separator 2 are connected in series and fixed side by side on the middle plate 6 horizontally, and the middle plate 6 is fixed on the first-stage The upper part of the barrel body of the dust collecting barrel 3; the secondary dust collecting barrel 4 is located in the primary dust collecting barrel 3. The first air inlet 101, the first air outlet 102 and the first dust outlet 103 are arranged on the side wall of the first-stage cyclone separator 1, and the first conical filter screen cover 104 is arranged inside it. The first cyclone cavity and the first air outlet cavity communicated, the first air inlet 101 and the first dust outlet 103 communicate with the first cyclone cavity, and the first air outlet 102 communicates with the first air outlet cavity; Simil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com