Method for partitioning total output of single shaft gas-steam combined cycle generating set

A technology of generator set and combined cycle, which is applied in gas turbine installations, machines/engines, combined combustion mitigation, etc., can solve the blindness of control operation, is not conducive to, and is not conducive to improving the reliability and economy of single-shaft gas-steam combined cycle units issues of sex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

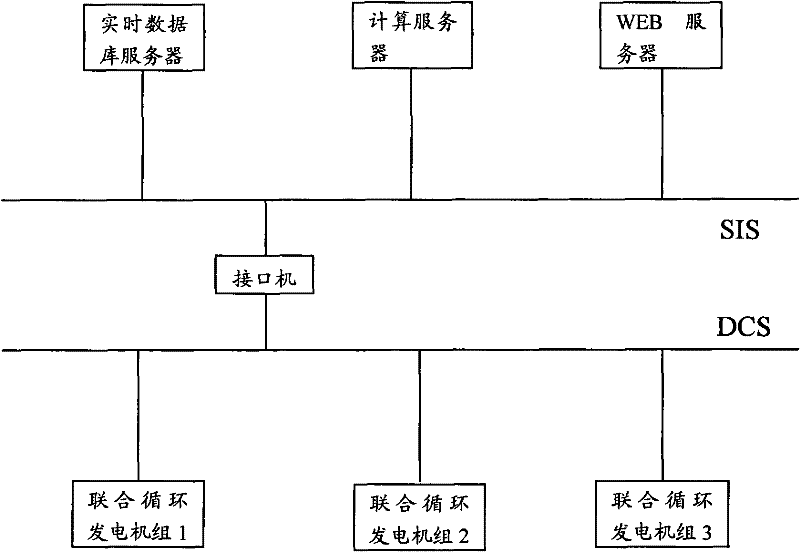

[0110] Hereinafter, the present invention will be described in more detail according to the embodiments of the 9FA single-shaft gas-steam combined cycle unit online performance calculation system and the single-shaft unit output division method with reference to the accompanying drawings.

[0111] In this embodiment, although the description is an example of the online performance calculation and the output division method of the single-shaft unit used in the 9FA single-shaft gas-steam combined cycle unit, this system and the calculation method used can also be applied to other combined cycle units.

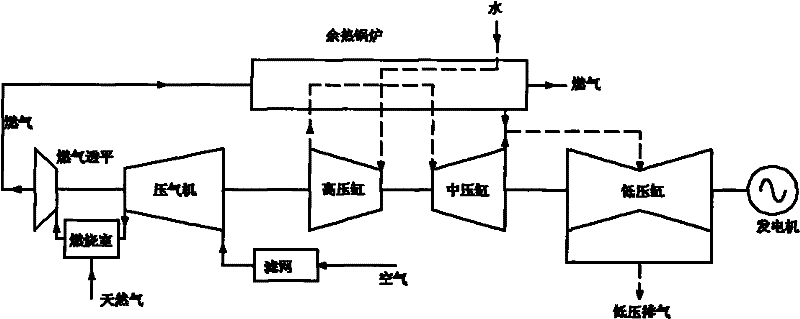

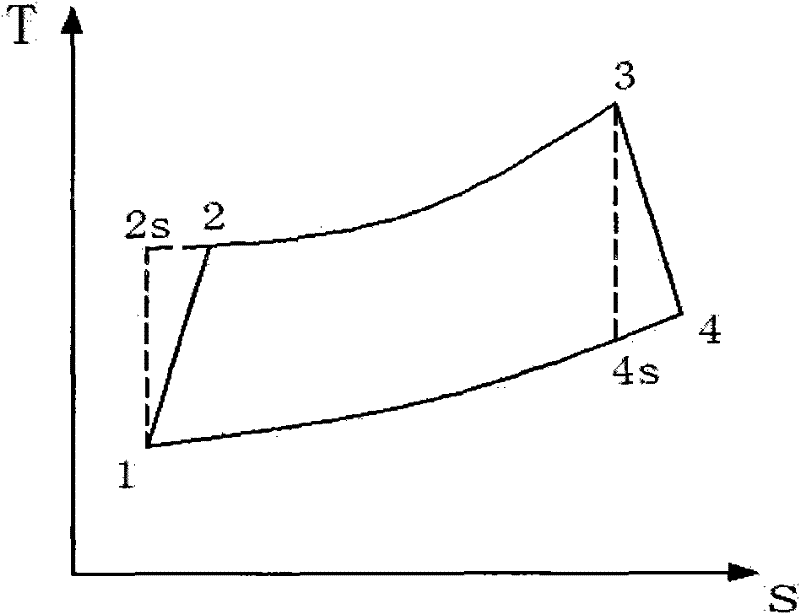

[0112] refer to figure 1 , 9FA single-shaft gas-steam combined cycle generator set is composed of gas turbine, waste heat boiler, steam turbine and generator, and the gas turbine, steam turbine and generator are connected on one shaft. The working process is that the fresh air is filtered by the filter, then enters the compressor to be compressed and boosted, and mixes with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com