Integrated controlled system and integrated controlled method for dynamic reactive power compensation based on touch screen, PLC and DSP

A comprehensive control and compensation system technology, applied in the comprehensive control reactive power compensation system, based on the touch screen, PLC and DSP comprehensive control dynamic reactive power compensation system field, can solve the problem of overcompensation, slow response speed, and inability to perform frequent switching Cutting and other problems, to avoid mis-input, prevent switching oscillation, and easy expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

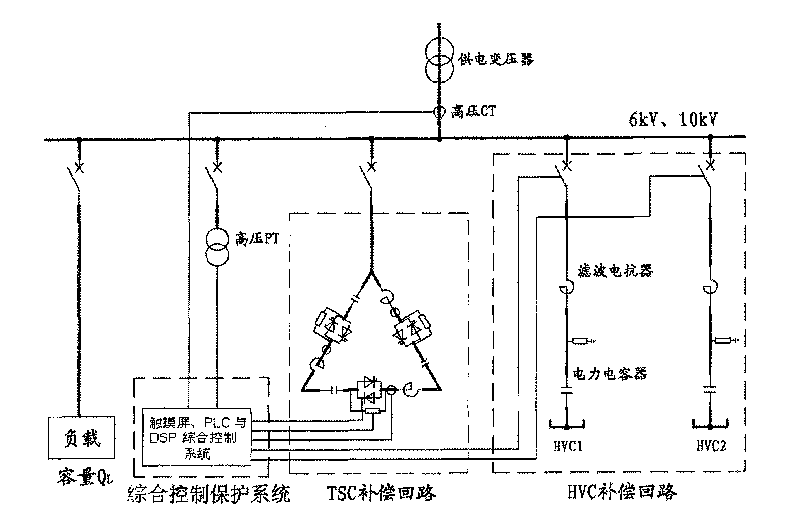

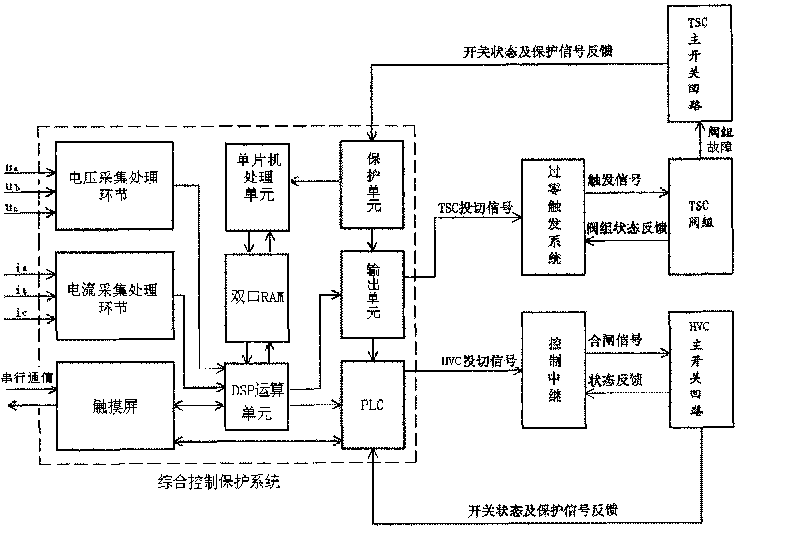

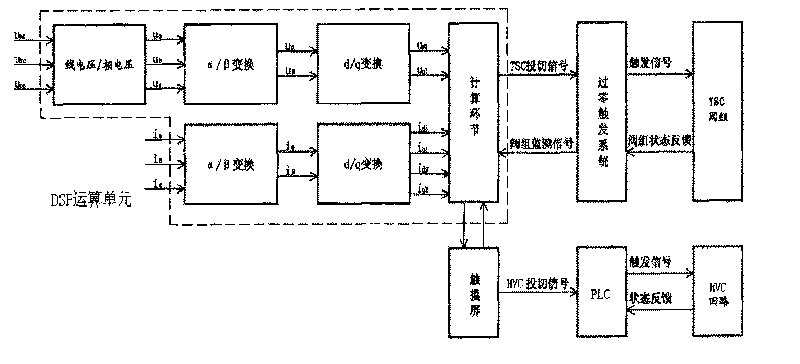

[0025] combined with Figure 1~4 Further description of the present invention: a comprehensive control reactive power compensation system of one TSC and two HVCs, wherein the TSC compensation loop and the HVC compensation loop are connected to the power grid at the adjacent load side. The HVC compensation circuit is connected in parallel to the power grid through filter reactors and vacuum contactors to compensate large-capacity reactive power. The TSC compensation circuit is connected in parallel to the power grid through the filter reactor and the thyristor valve group to perform reactive power fine adjustment. The comprehensive control and protection system is composed of touch screen, PLC and DSP computing unit, trigger pulse forming circuit, photoelectric isolation circuit, zero-crossing trigger system, and fault detection system. When the system needs capacitive reactive power, the DSP calculation unit calculates the required reactive power capacity, controls the switch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com