Novel compound sealing machine of structural film materials

A technology of structural film and ironing machine, which is applied in the field of structural film material compound ironing machine, can solve the problems of inconvenient operation and low production efficiency, and achieve the effects of high production efficiency, improved production efficiency and increased degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

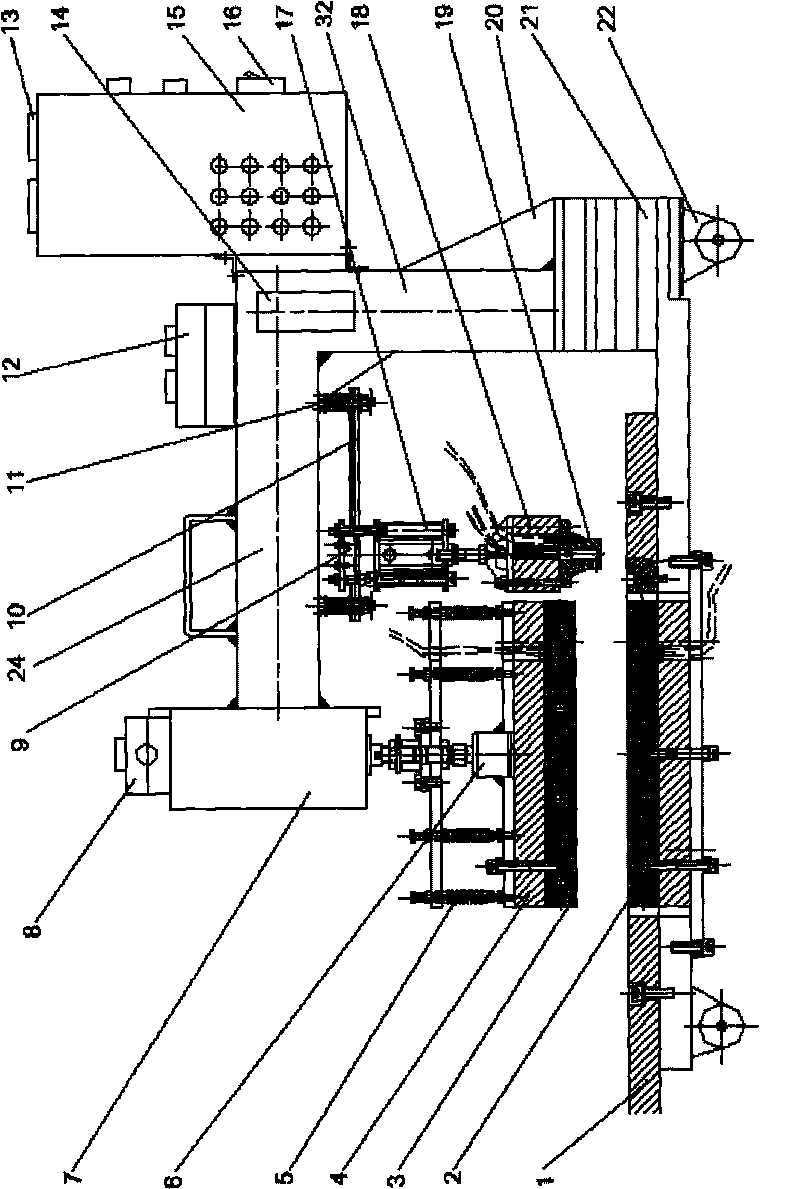

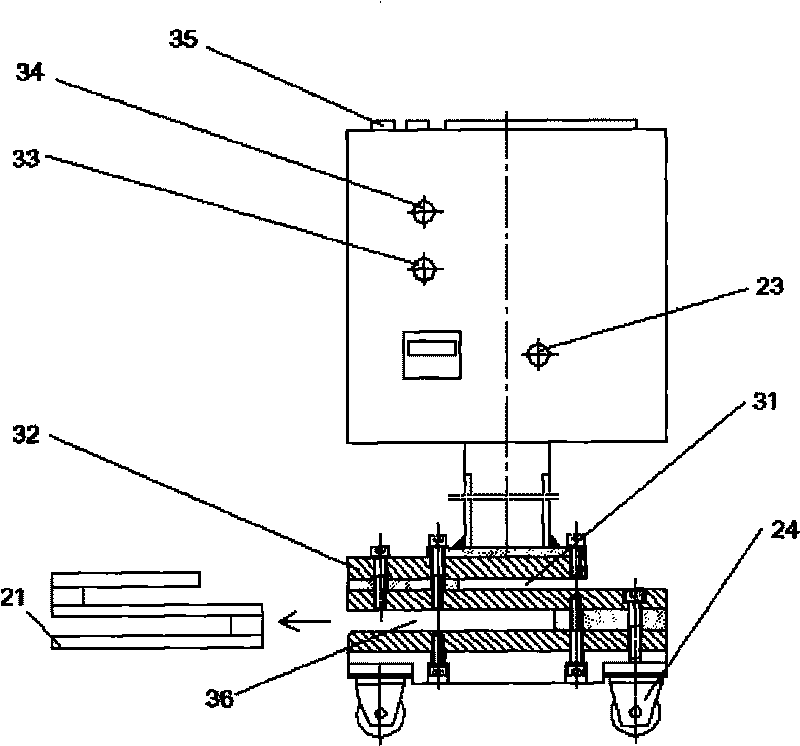

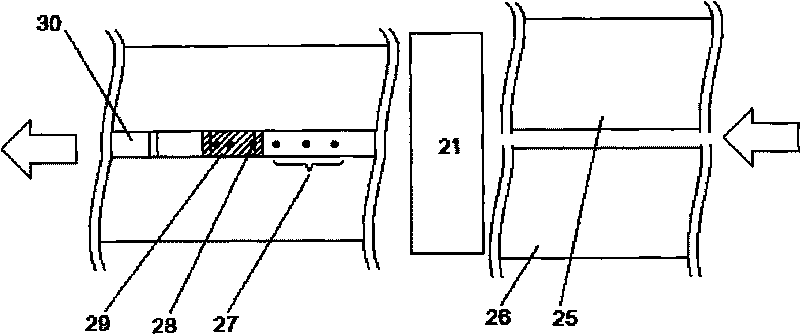

[0043] Such as figure 1 As shown, a new type of composite ironing machine for structural membrane materials, including the fuselage and the following components located on the fuselage:

[0044] Integral ironing head, the integral ironing head driving part 7 connected with the integral ironing head, the integral ironing head driving part 7 is used to drive the vertical integral ironing movement of the upper heating integral ironing head 3;

[0045] Spot ironing head 19, a spot ironing head driving part 17 connected to the spot ironing head 19, the spot ironing head driving part 17 is used to drive the spot ironing head 19 to move vertically;

[0046] The control part is connected with the integral ironing head, the integral ironing head driving part 7, the spot ironing head 19 and the spot ironing head driving part 17, and is used to control the integral ironing head, the integral ironing head driving part 7, the spot ironing head 19 and the operation of the driving part 17 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com