Windproof nozzle for welding double-layer gas shield

A gas protection, double-layer technology, applied in the direction of welding equipment, electrode characteristics, arc welding equipment, etc., can solve the problem of easy occurrence of arc craters and achieve the effect of avoiding arc craters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

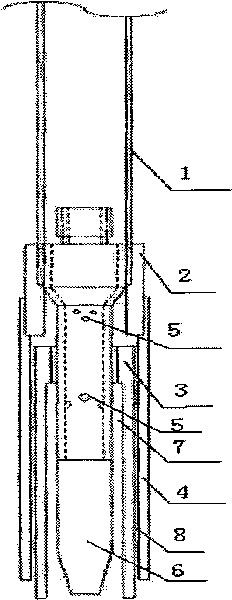

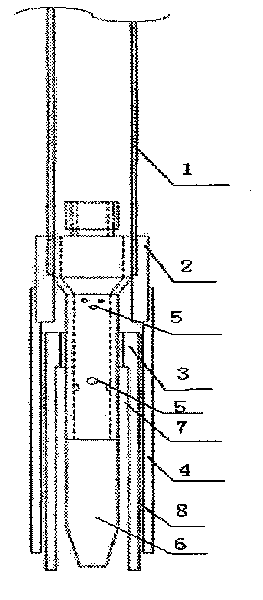

[0014] like figure 1 As shown, a windproof nozzle for double-layer gas shielded welding includes a connecting sleeve 2, an inner nozzle 3, an outer nozzle 4, a vent hole 5, and a conductive tip 6. The conductive tip 6 is fixedly connected to the inner nozzle 3, and the conductive tip 6 and the inner nozzle 3 form an annular cavity 7 with one end closed and the other open; the outer nozzle 4 is fixedly connected to the contact tip 6 through the connection sleeve 2, and the contact tip 6, the connection sleeve 2, the outer nozzle 4 and the A cavity 8 is formed between the inner nozzles 3 ; the contact tip 6 is provided with vent holes 5 in the annular cavity 7 and the part inside the cavity 8 . The contact tip 6 is threadedly connected with the inner nozzle 3 . The outer nozzle 4 is threadedly connected with the contact tip 6 through the connecting sleeve 2 . The diameter of the contact tip 6 in the annular cavity 7 is smaller than the diameter of the contact tip 6 in the cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com