Fringe and stalk harvesting type corn harvester

A harvester and corn technology, applied to harvesters, agricultural machinery and implements, applications, etc., can solve the problem of corn harvesting that does not fundamentally solve the problem of working principle and structure, and achieve the effect of realizing the diversification of straw

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings. The present embodiments are descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

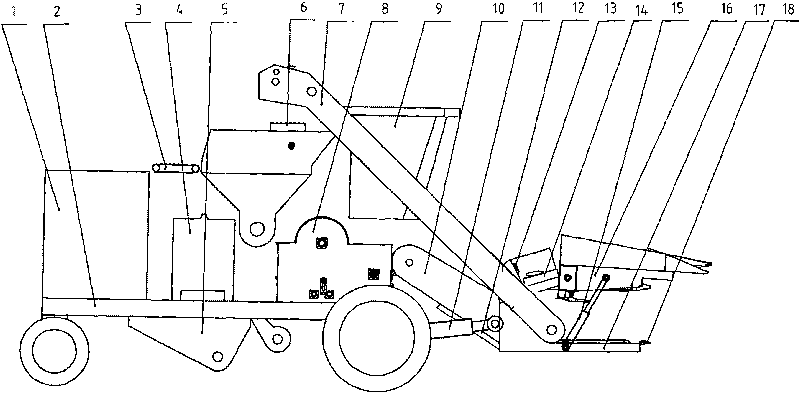

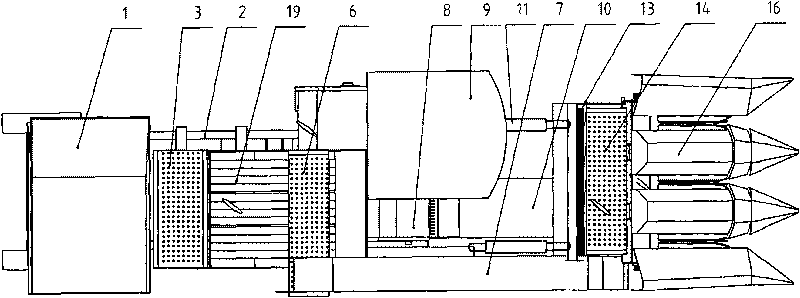

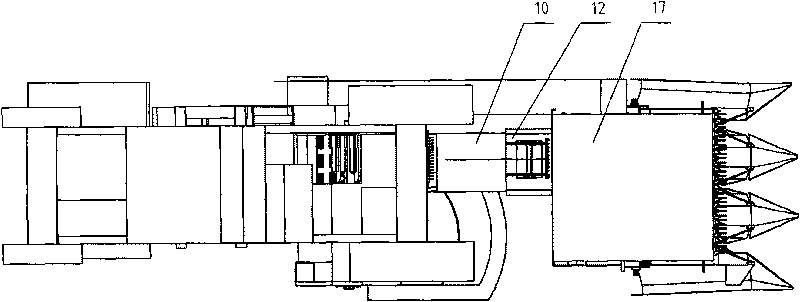

[0042]A corn harvester with both ears and stalks, comprising a vehicle 2, a cab 9 installed on the vehicle, a longitudinal elevator assembly 7, a corn thrower 3, an engine assembly 4, and an overturned corn cob bin 1 , corn grain collection box 5, straw clearing and straw crushing device 8, straw conveyor 10, straw gathering and sorting device 17, and grain divider and shield assembly 16 constitute. An oil cylinder 11 is installed on the vehicle, and the plunger of the oil cylinder is installed on the straw gathering and sorting device to realize the angle swing of the straw gathering and sorting device, so that the stem cutter 18 fixed at the front end of the straw gathering and sorting device can be adjusted. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com