Shielded ultrasound probe socket and assembling jig thereof

An ultrasonic probe and shielded technology, which is applied in the field of shielded ultrasonic probe sockets and their assembly fixtures, can solve the problems of high processing precision requirements, high cost of hexagonal copper studs, and low assembly efficiency, so as to reduce processing costs and avoid Tin cracking of electronic components and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, the present invention will be further described in detail based on the drawings and embodiments:

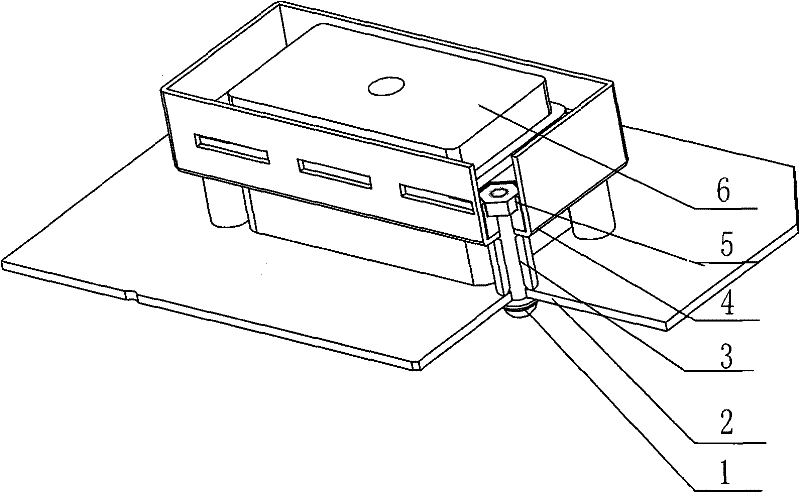

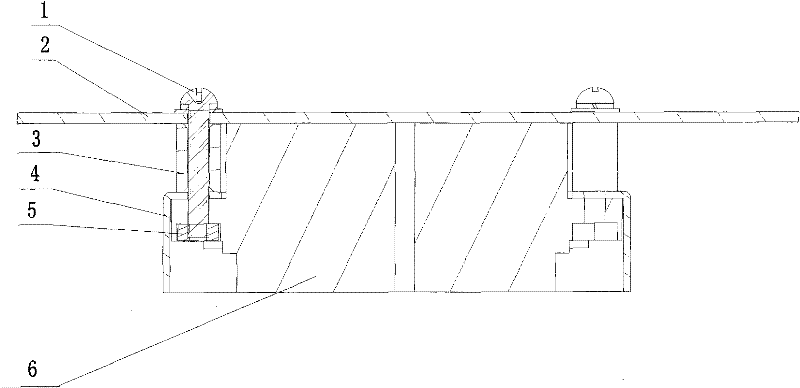

[0023] Such as figure 1 with figure 2 As shown, the shielded ultrasonic probe socket of the present invention includes an ultrasonic probe socket 6, an open ultrasonic probe socket shielding box 4, and an ultrasonic probe socket circuit board 2. The ultrasonic probe socket 6 is fixed on the ultrasonic probe socket circuit board 2 with an open mouth The ultrasonic probe socket shielding box 4 surrounds the ultrasonic probe socket 6, and also includes a screw 1, a nut 5 and a cylindrical support column 3. At least one nut slot is provided at each end of the ultrasonic probe socket 6, the screw 1, the nut 5 and the round The number of cylindrical support columns 3 corresponds to the number of nut clamping slots. Nut 5 is placed in the nut clamping slot. The cylindrical support column 3 is located between the ultrasonic probe socket circuit board 2 and the open ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com