Gas stove

A gas stove and gas technology, applied in the field of stoves, can solve the problems of high emission of harmful substances, low efficiency, insufficient combustion, etc., and achieve the effect of reducing emission and improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

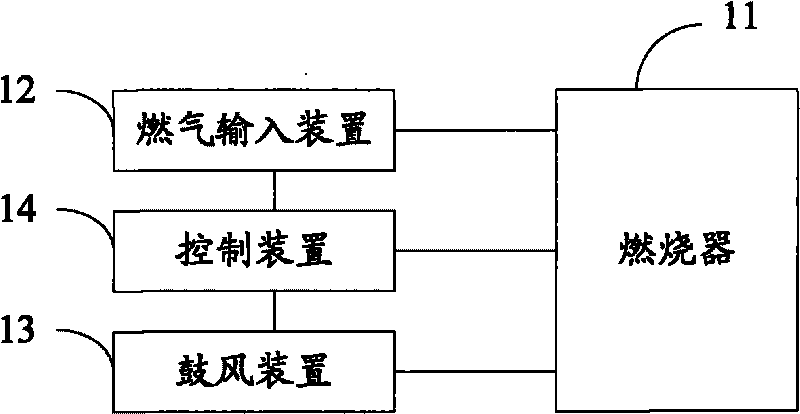

[0027] Embodiment two, please refer to figure 2 It is a structural diagram of another embodiment of a gas stove in the present invention;

[0028] The burner 21 is connected to the gas input device 22, the blast device 23 and the control device 24, and is used to accept the control device to control 24 to ignite, and burn the gas input by the gas input device 22 and the air mixed gas input by the blast device 23;

[0029] The gas input device 22 is connected to the control device, accepts the control of the control device, and adjusts the gas input amount;

[0030] The blower device 23 is connected to the control device, receives the control of the control device, and adjusts the air input volume;

[0031] The control device 24 is used to control the gas input by the gas input device and the air volume input by the blower device according to a preset ratio.

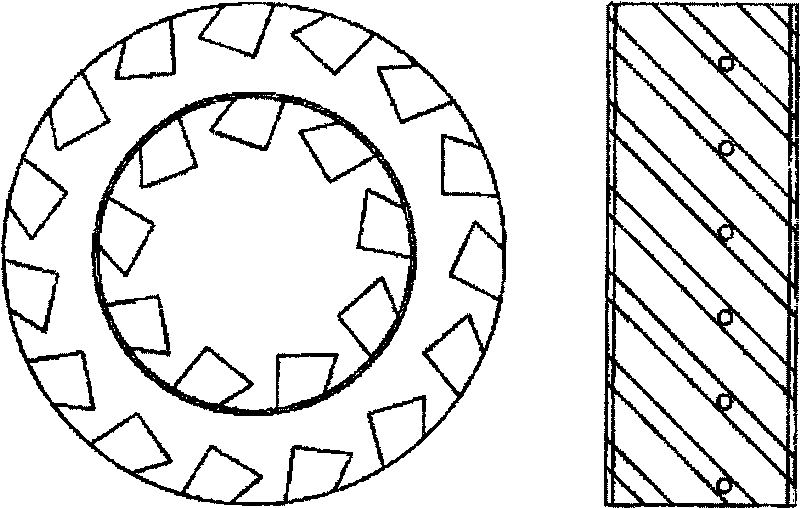

[0032] Further, the burner 21 may also include a mixing chamber 211, a constant flow device 212 and a combustion por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com