Belt conveyor based multi-material belt weighing system

A belt conveyor and belt weighing technology, which is applied in the direction of weighing equipment, weighing, and measuring devices for continuous material flow, can solve the problems of labor-consuming and time-consuming material layers, single control mode, and unfavorable user selection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The specific implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples, but the protection scope of the present invention should not be limited thereby.

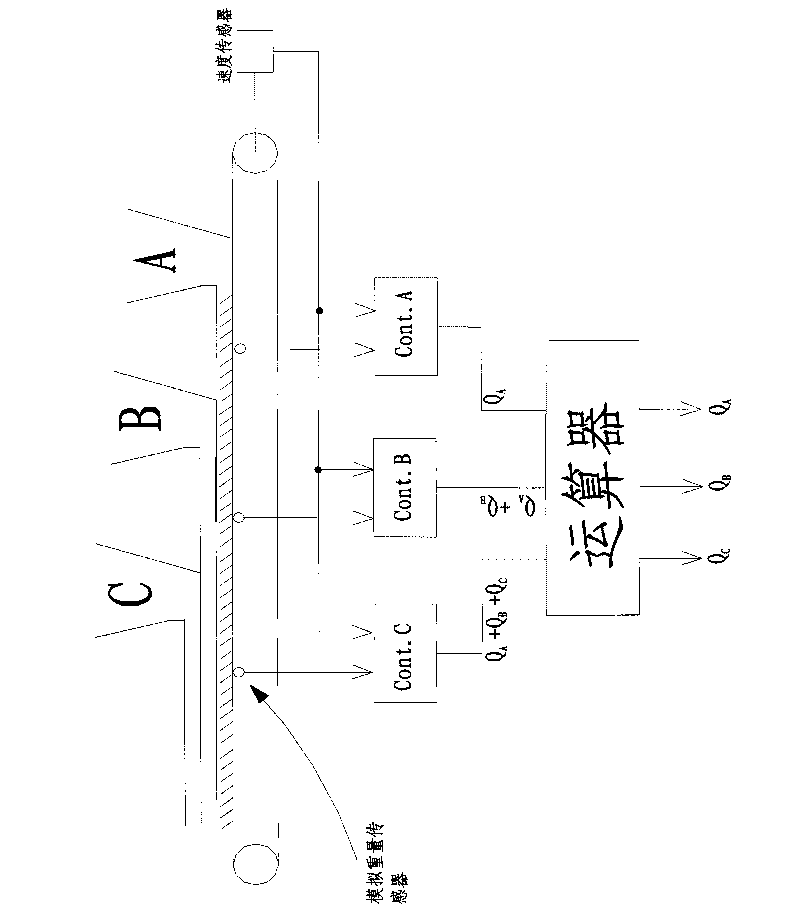

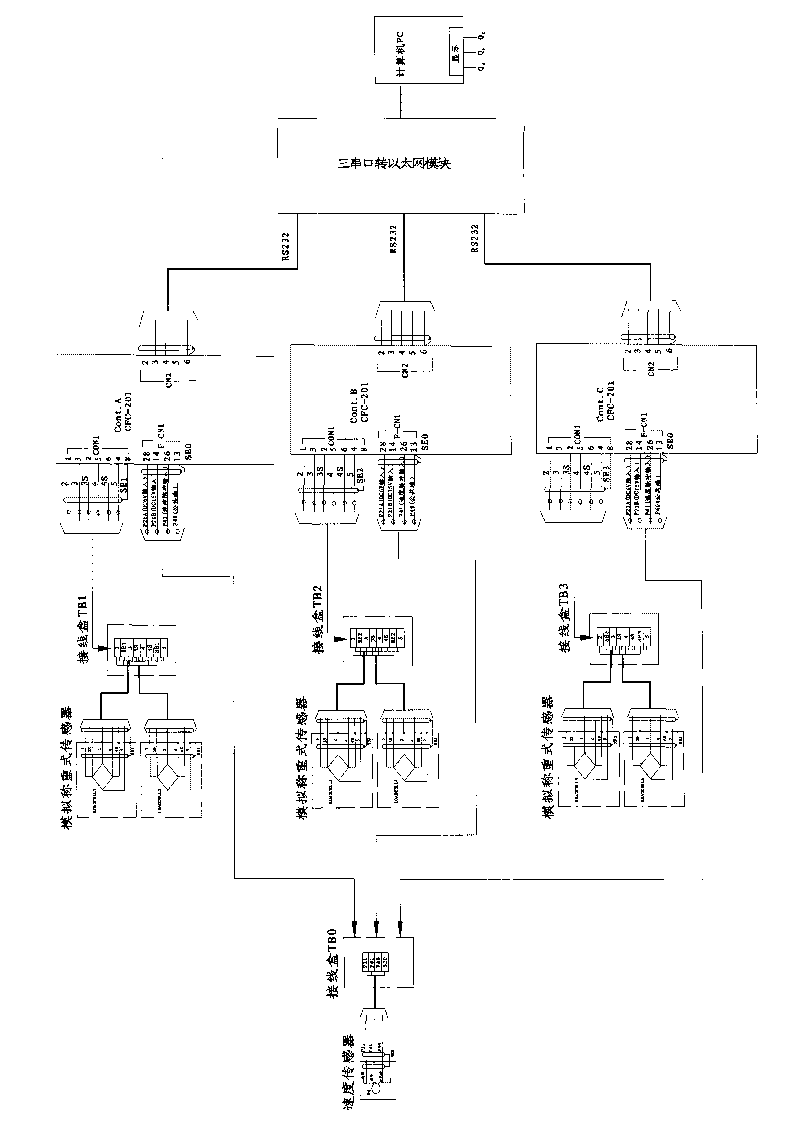

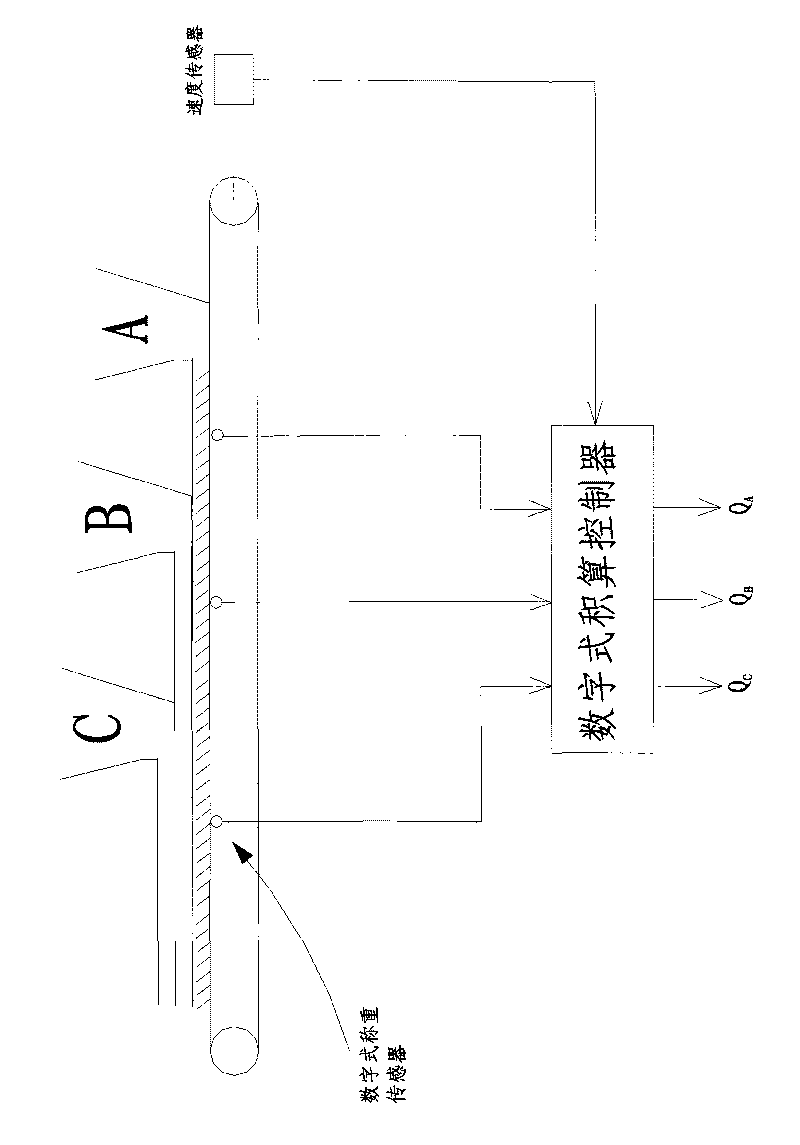

[0063] see Figure 9-1 , Figure 9-2 , Figure 9-3 , Figure 10, Figure 11 , Figure 12, Figure 13.

[0064] The present invention is based on the multi-material belt weighing system of a belt conveyor, comprising a belt conveyor 17 ( Figure 9-3 ) and the three feeding ports 1, 2, 3 above the belt conveyor ( Figure 9-2 ), the whole belt conveyor consists of a sealed shell body 5 ( Figure 9-2 ) protection, inspection window 4 ( Figure 9-2 ) is used for daily inspection and maintenance of equipment, and there are 2 sets of explosion-proof lighting devices 8 ( Figure 9-2 ) for internal maintenance. The belt conveyor includes three sets of weighing devices for material measurement, a set of speed sensor 9 ( Figure 9-2 )...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com