Variable displacement compressor and displacement control system

A capacity control and compressor technology, which is applied in the direction of liquid variable capacity machinery, pump control, mechanical equipment, etc., can solve the problems of the absence of capacity control devices, etc., and achieve the effect of ensuring driving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

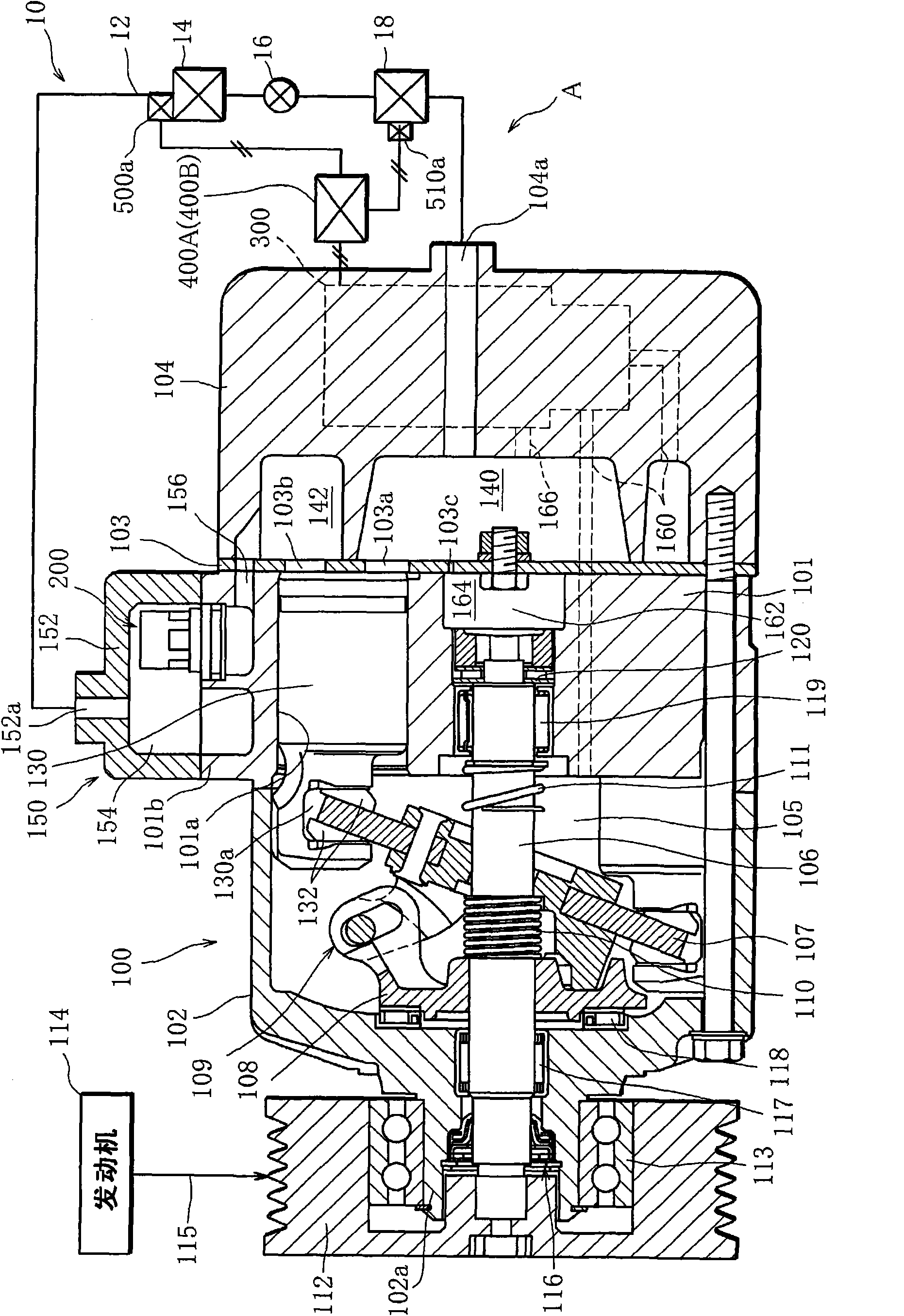

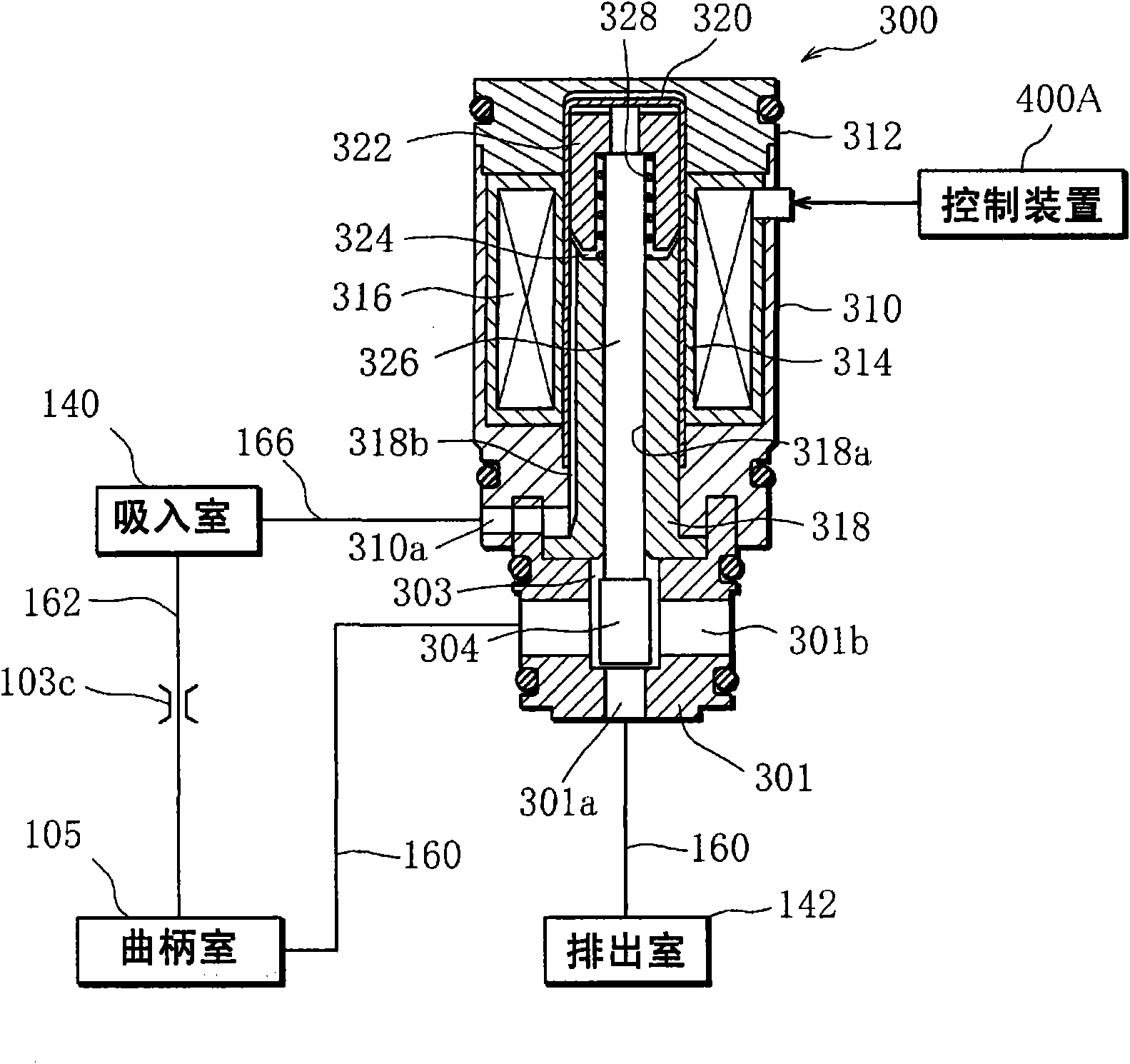

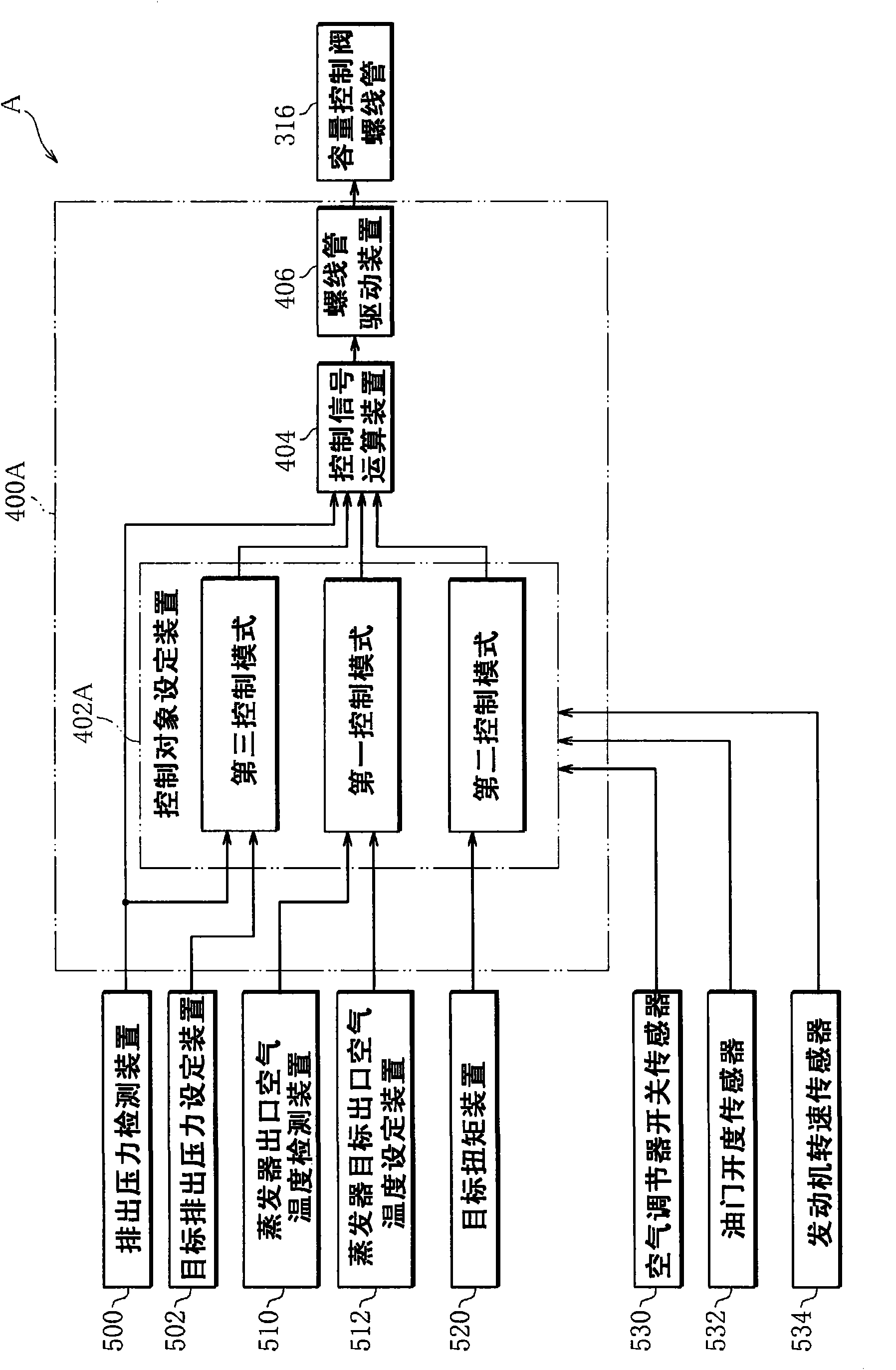

[0081] Hereinafter, the displacement control system A of the variable displacement compressor according to the first embodiment will be described.

[0082] figure 1 A refrigeration cycle 10 of a vehicle air-conditioning system to which the capacity control system A is applied is shown, and the refrigeration cycle 10 includes a circulation path 12 through which a refrigerant as a working fluid circulates. In the circulation path 12, a compressor 100, a heat radiator (condenser) 14, an expander (expansion valve) 16, and an evaporator 18 are interposed sequentially from the flow direction of the refrigerant. If the compressor 100 works, refrigeration The agent circulates in the circulation path 12. That is, the compressor 100 performs a series of steps including a suction process of refrigerant, a compression process of the suctioned refrigerant, and a discharge process of the compressed refrigerant.

[0083] The evaporator 18 also forms part of the air circuit of the vehicular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com