Induction sealing device for heat sealing packaging material for producing sealed packages of pourable food products

一种包装材料、密封设备的技术,应用在包装密封/紧固、包装、运输包装等方向,能够解决支承体易于开裂、缩短密封设备工作寿命等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

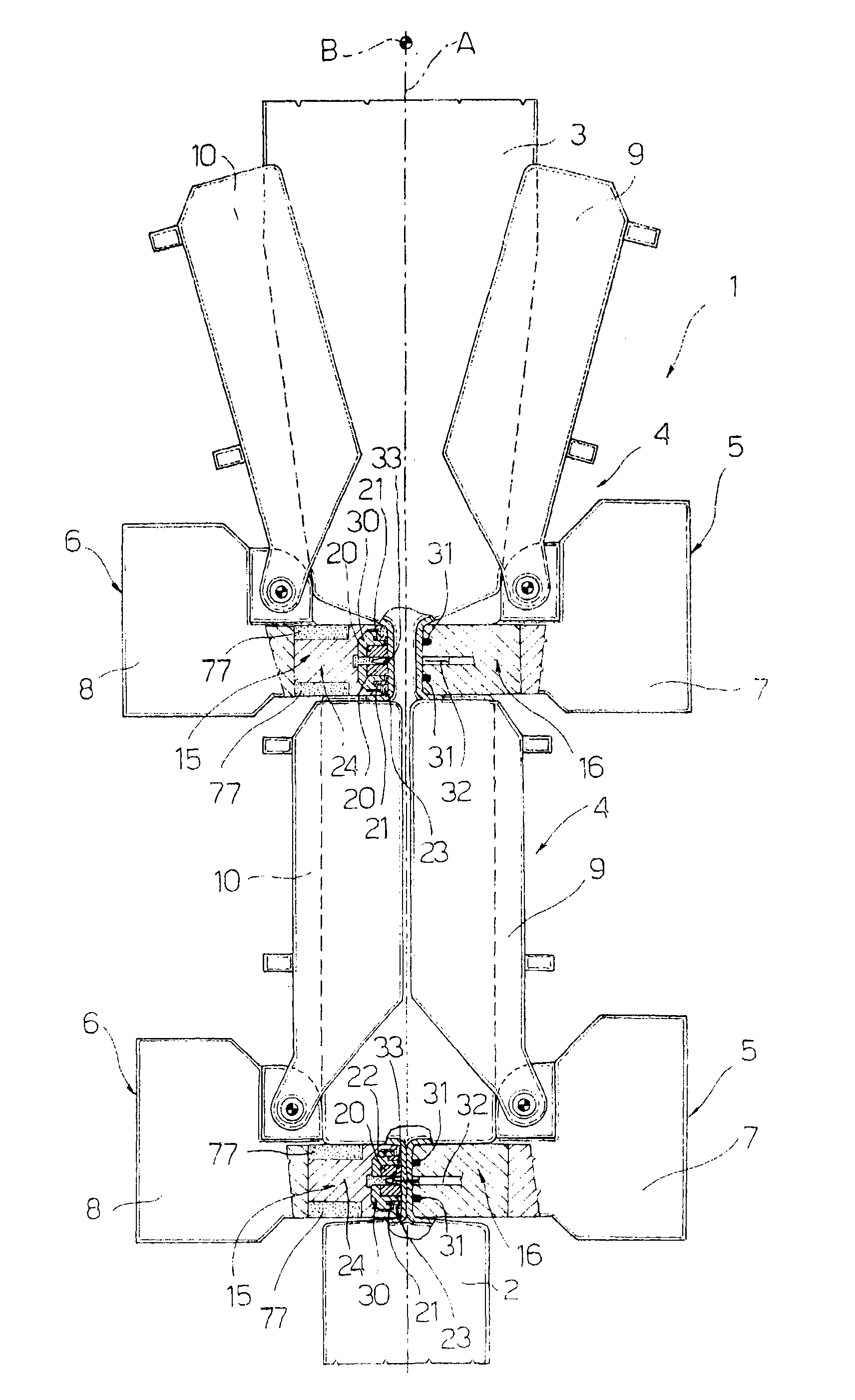

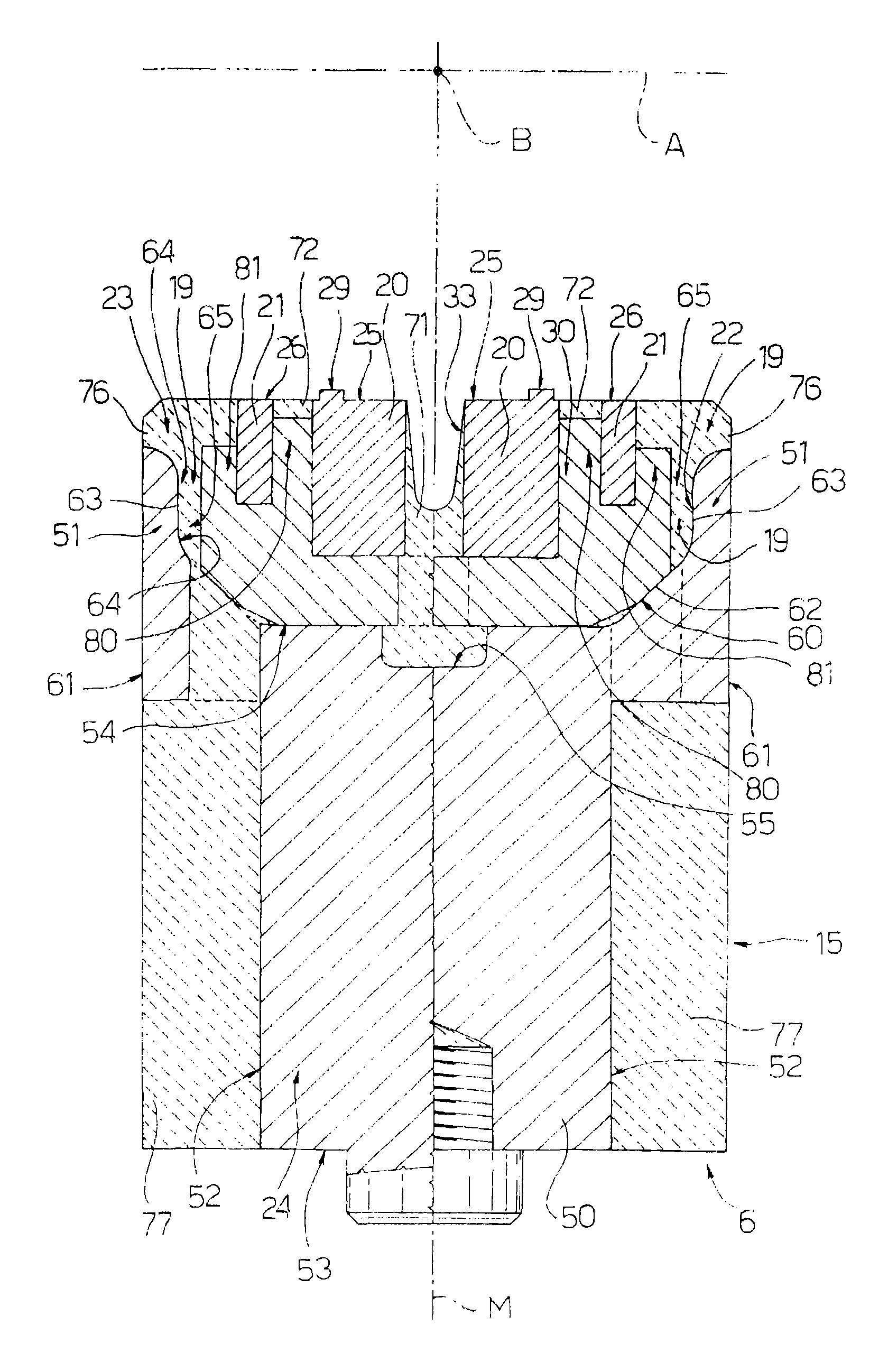

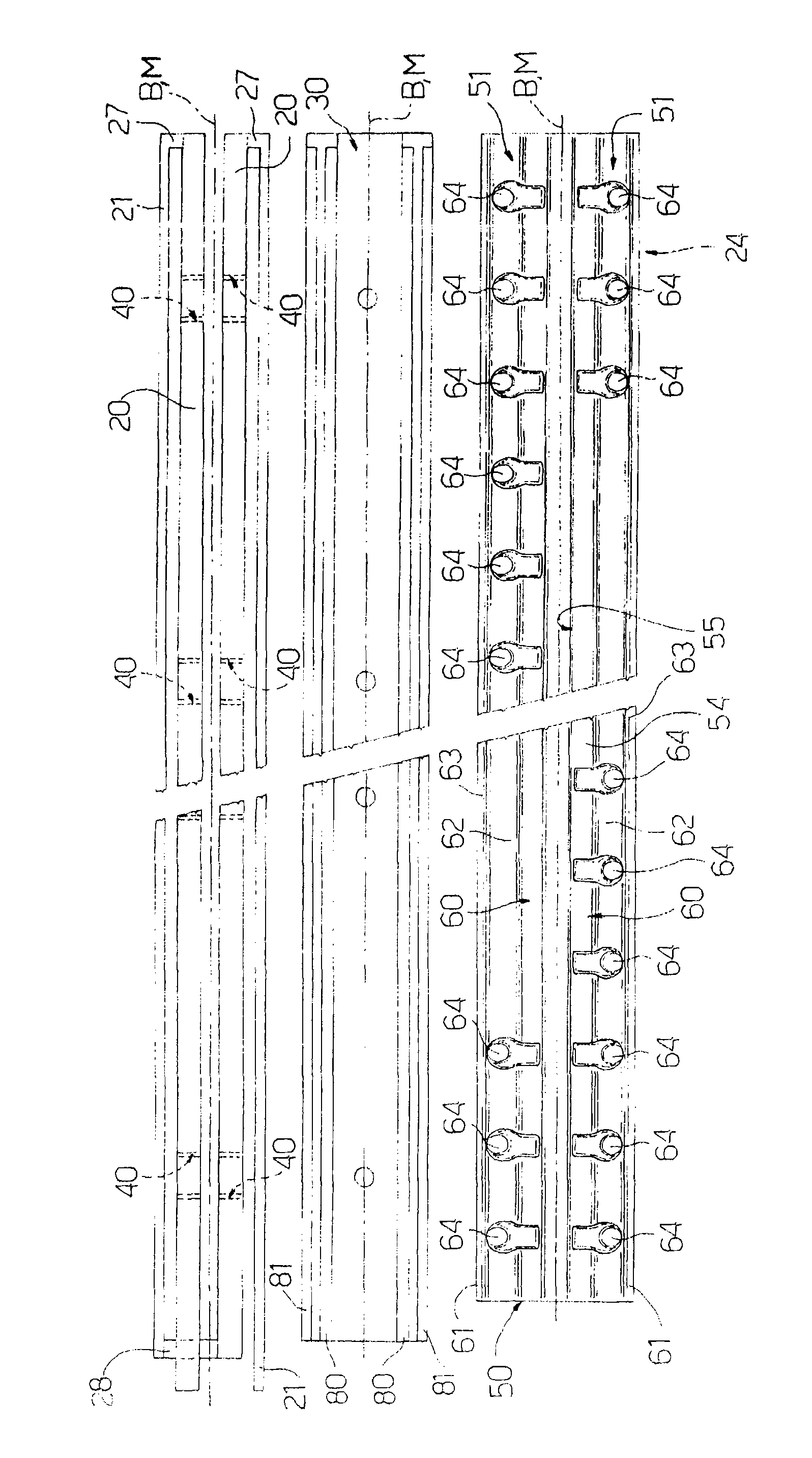

[0024] figure 1 The number 1 in overall designates a packaging unit for producing aseptic sealed packages 2 of pourable food products such as pasteurized or UHT milk, fruit juices, wine, etc. from a tube 3 of packaging material.

[0025] The packaging material has a multilayer structure (not shown) and comprises layers of fibrous material (usually paper) covered on both sides by corresponding layers of heat-sealable plastic material (e.g. polyethylene); The sides of the packaging material for the food product in package 2 also have a layer of electrically conductive barrier material, such as aluminium, which in turn is covered by one or more layers of heat-sealable plastic material.

[0026] A tube 3 is formed in a known manner upstream of the unit 1 by folding longitudinally and sealing a strip of heat-sealed thin strip material, said tube 3 being filled with sterilized or aseptically processed food products and produced by known The equipment (not shown) is fed in direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com