Conducting strip structure

A conductive sheet and connecting sheet technology, which is applied to contact parts, welding/welding connections, riveting connections, etc., can solve the problems of increasing the cost of stamping dies, the inability to make conductive sheet structures, and the increase in the cost of conductive sheet structures, so as to reduce waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

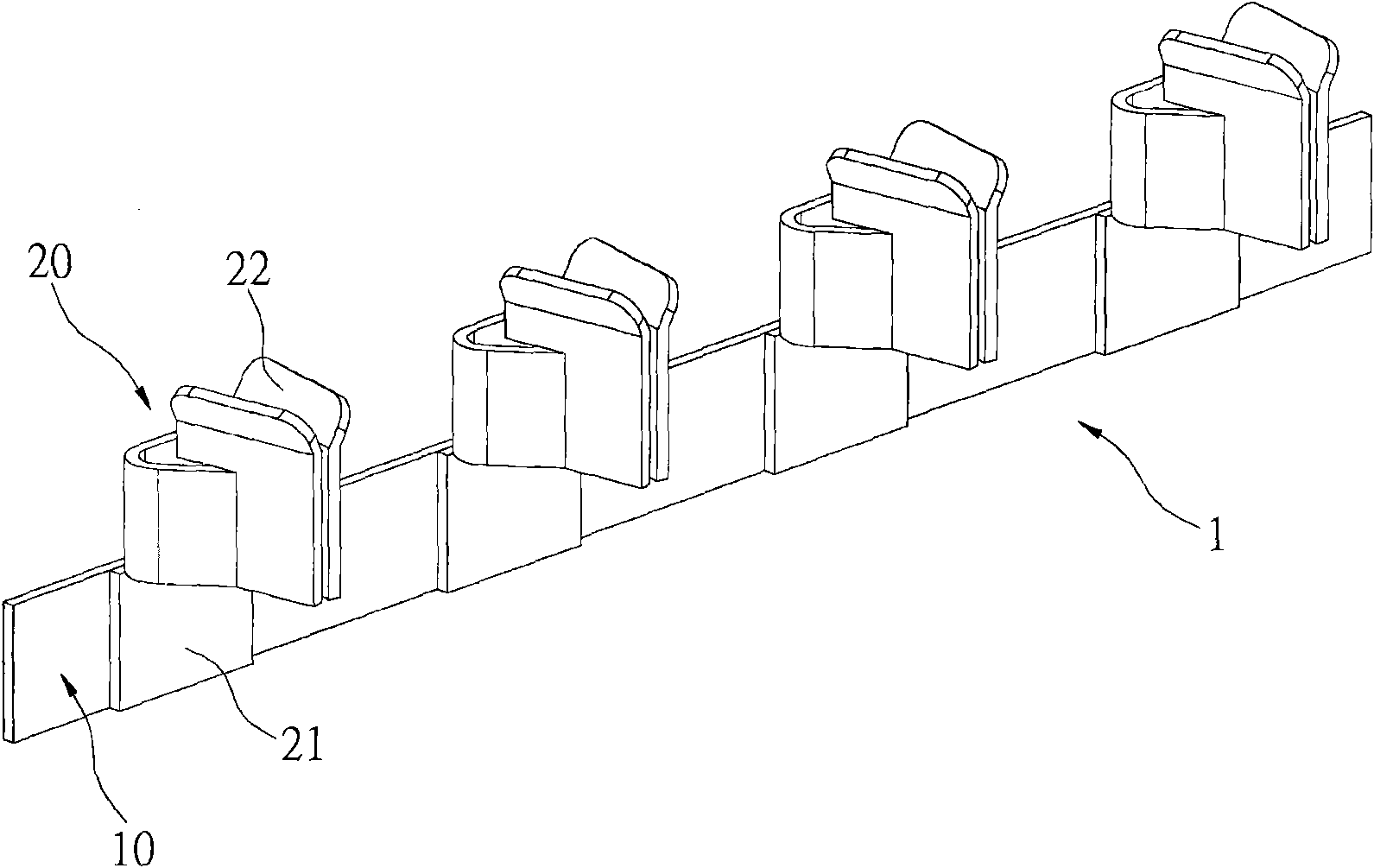

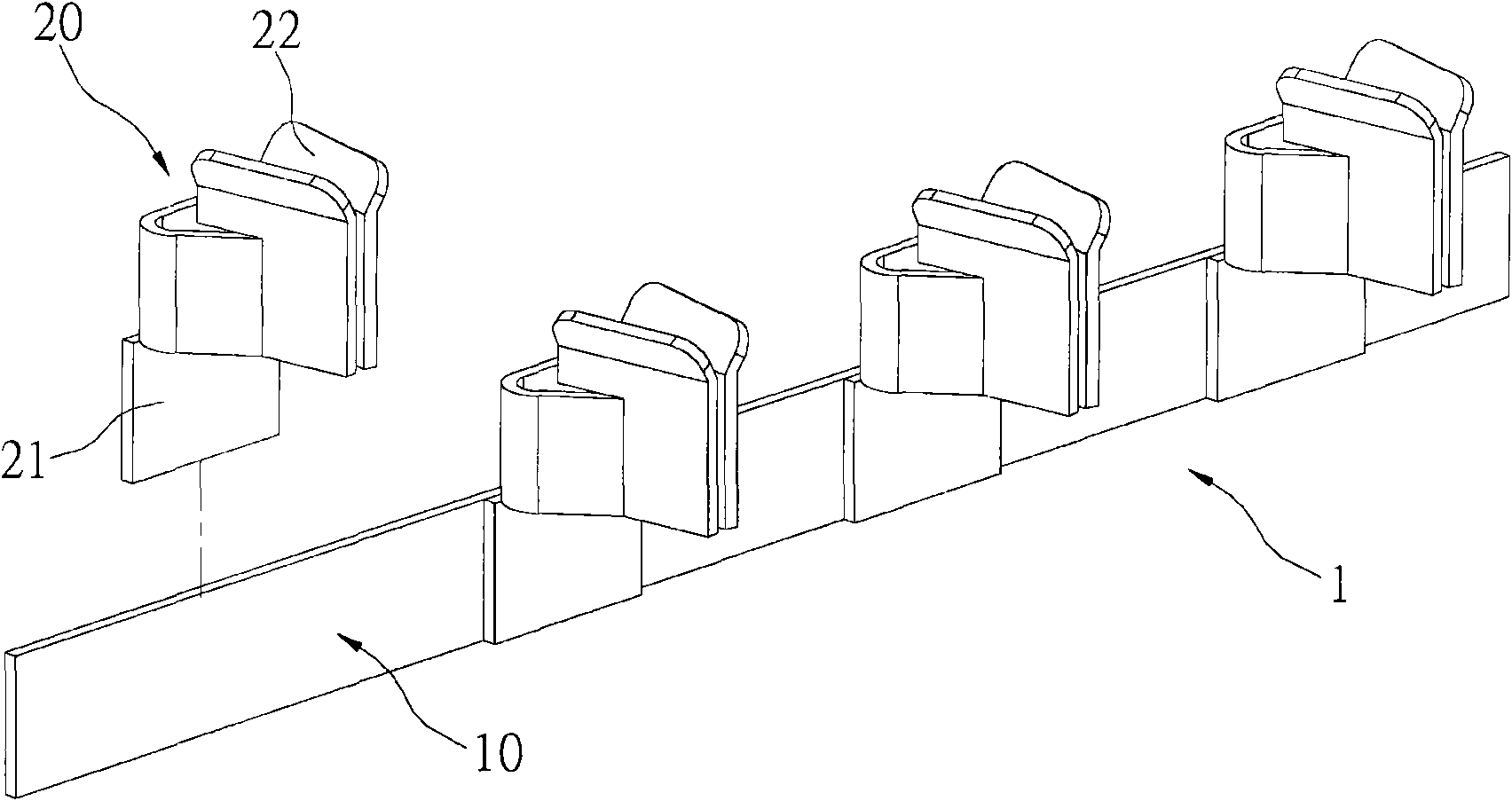

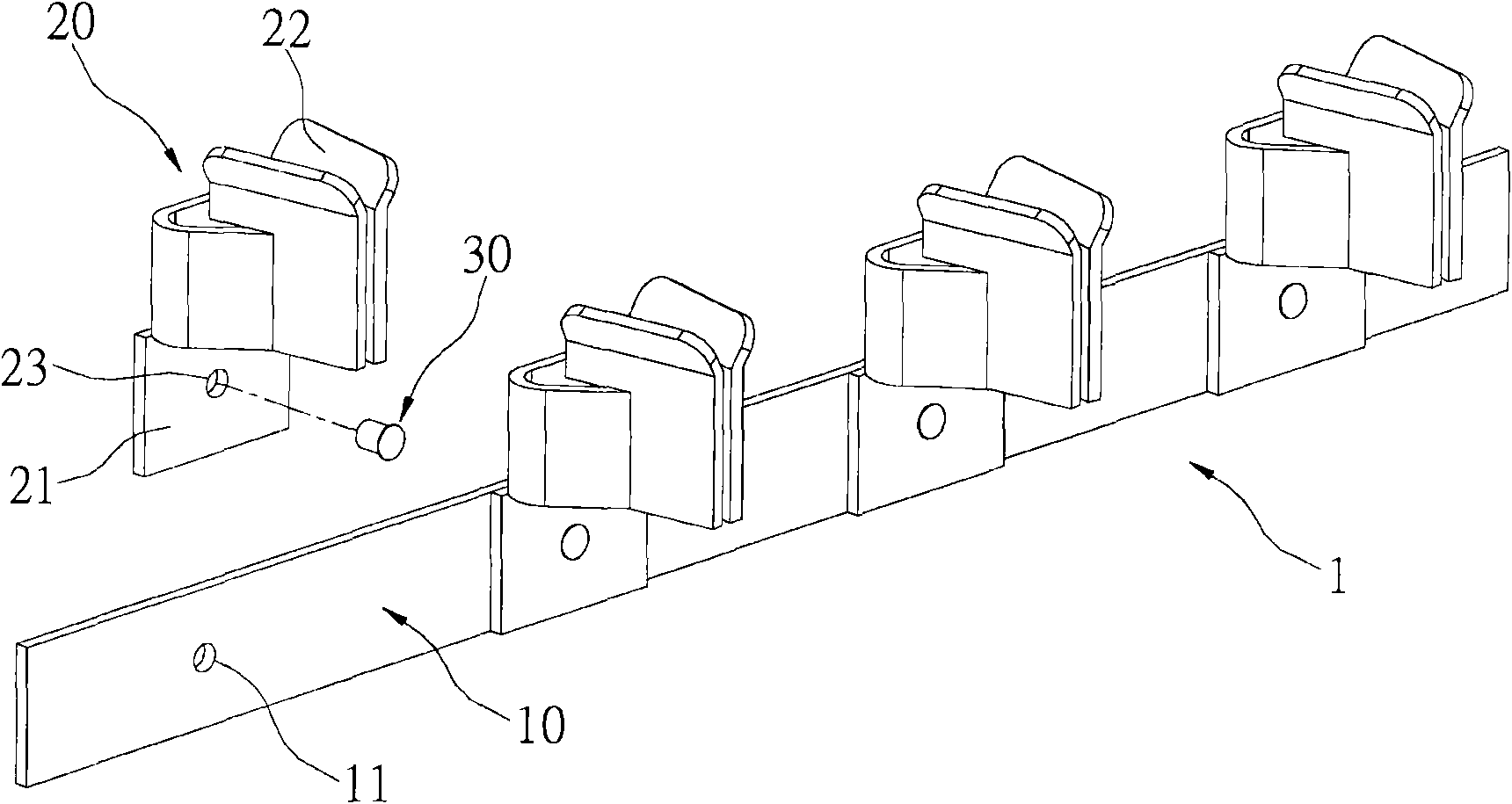

[0036] see figure 1 and figure 2 , which shows the conductive sheet structure 1 of the present invention, which includes: a connecting sheet 10 and a plurality of contact units 20 .

[0037] The conductive sheet structure 1 can be installed in a power socket (not shown), the connecting piece 10 is used to electrically connect with the power line of the power socket, and each contact unit 20 is respectively corresponding to the socket of the power socket hole.

[0038] The connection piece 10 and the contact unit 20 are made of metal materials with high conductivity, such as copper, and the connection piece 10 and the contact unit 20 can be made of different metal materials. Both the connecting piece 10 and the contact unit 20 are manufactured into their required structural shapes by a punching machine.

[0039] The connecting piece 10 is an elongated sheet body, which is formed by punching a metal plate with a width approximately the same as that of the connecting piece 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com