Electronic component unit and method for manufacturing same

A technology of electronic components and manufacturing methods, which is applied in the direction of fixed capacitance parts, electrical components, circuits, etc., can solve problems such as position deviation, inability to obtain electronic component unit characteristics, unstable position of electronic component components, etc., and achieve a suppressed position offset effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

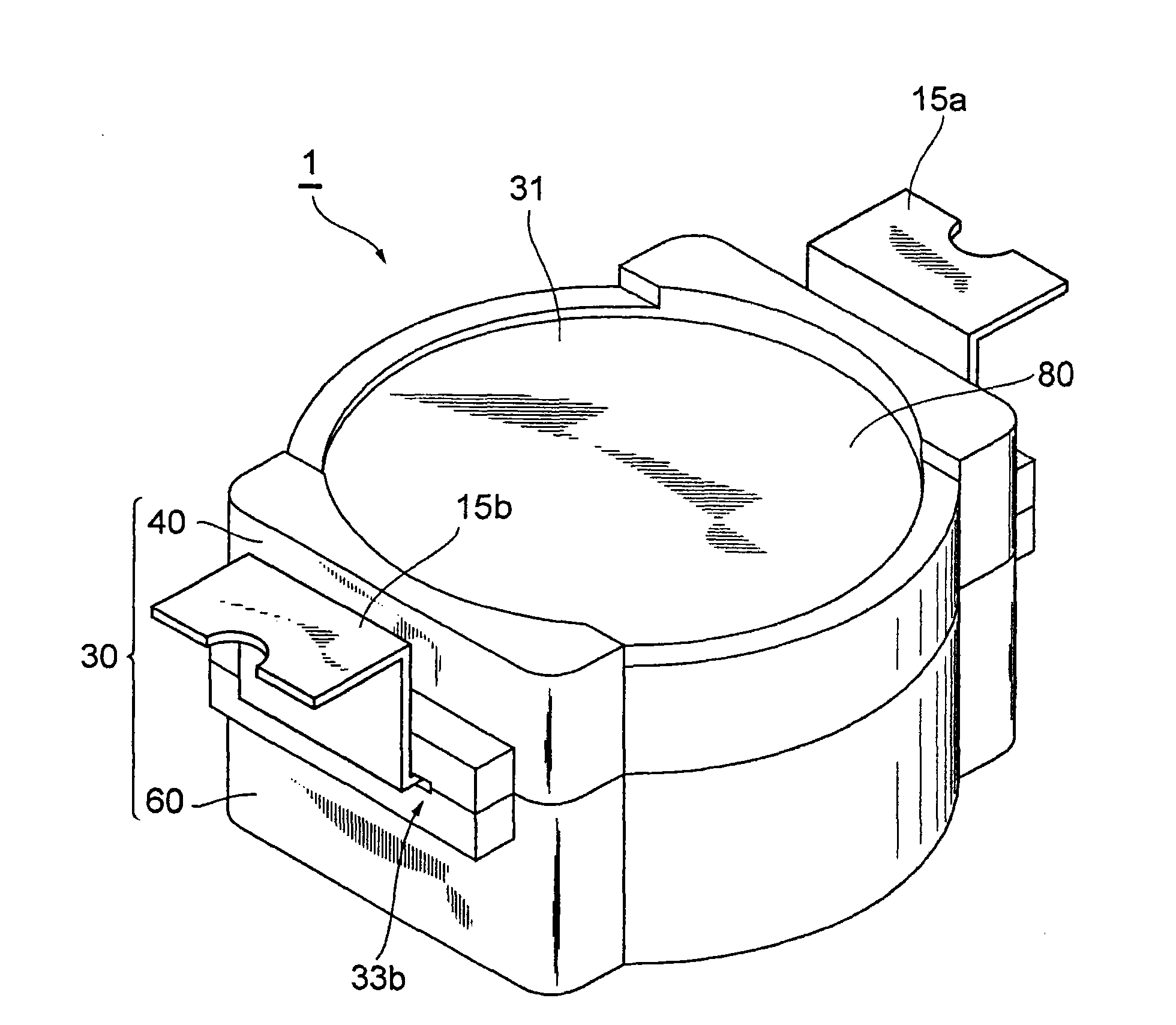

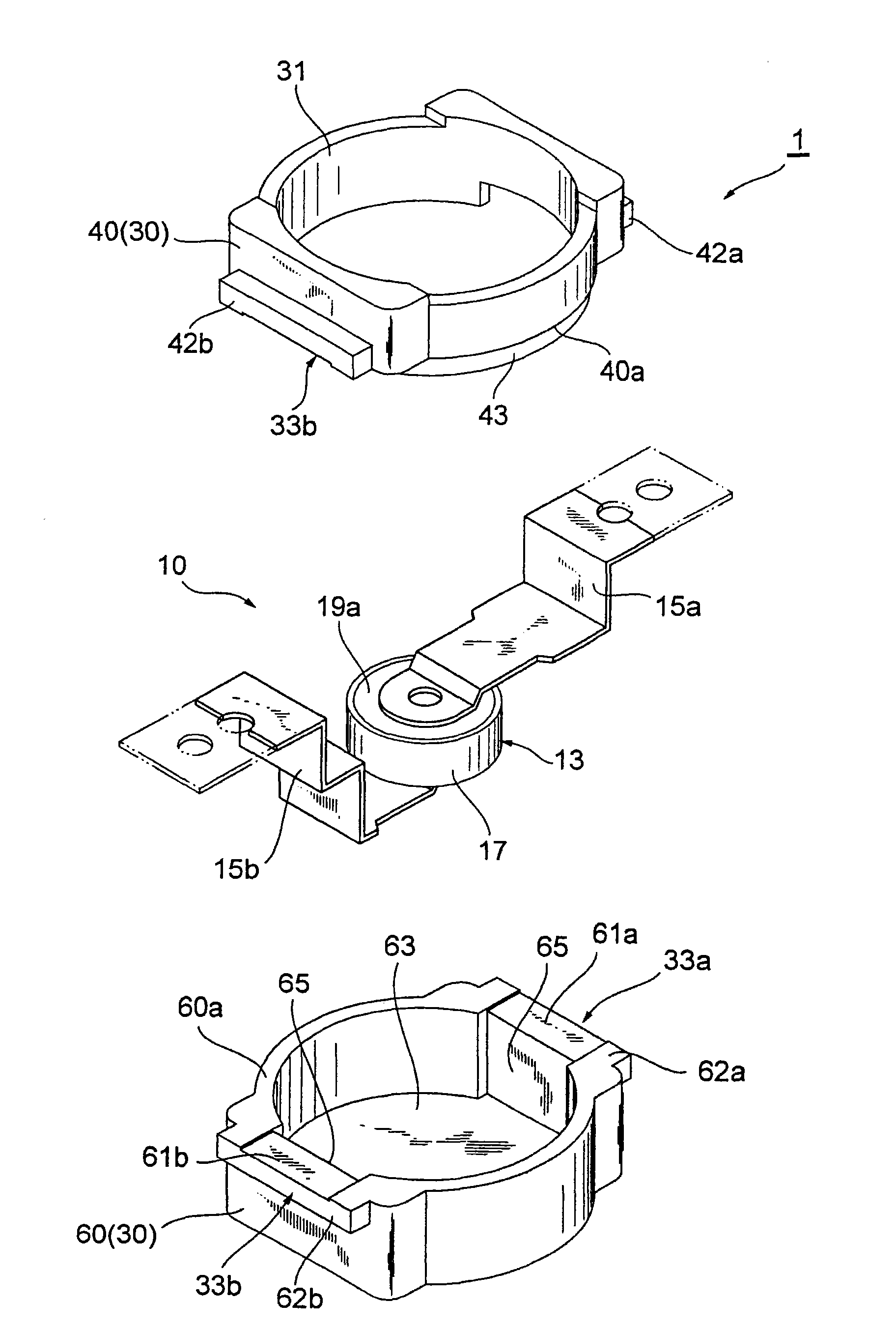

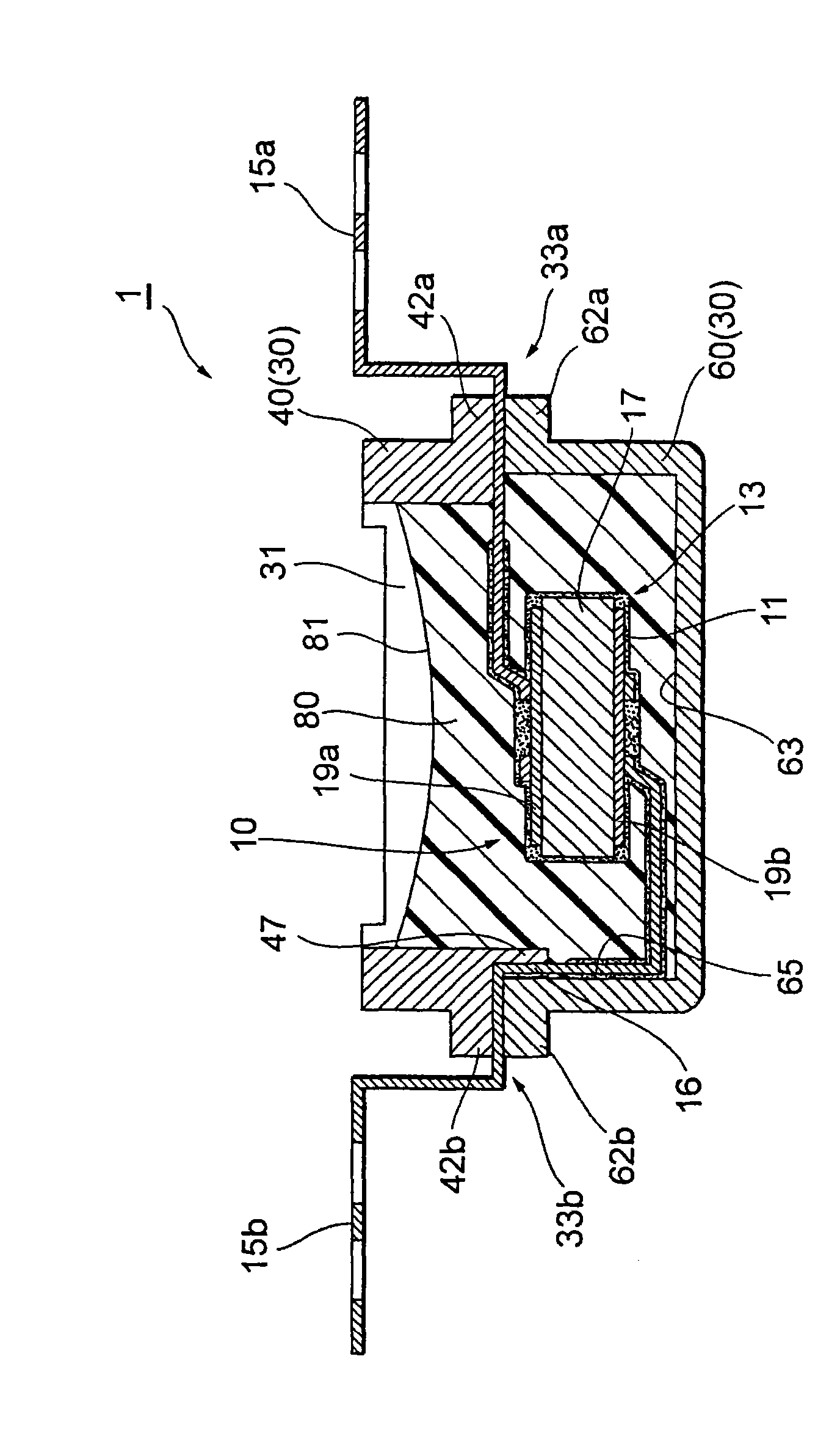

[0035] Figure 1 ~ Figure 3It shows the surface mount type capacitor unit 1 which is 1st Embodiment of the electronic component unit which concerns on this invention. The capacitor unit 1 is an injection type resin-molded medium-voltage capacitor unit, and includes a capacitor portion (electronic component) 10 and an exterior container 30 accommodating the capacitor portion 10 . This capacitor unit 1 is formed by accommodating the capacitor part 10 in the outer container 30 with its lead frames (metal terminals) 15a, 15b exposed outside the outer container 30, and performing resin molding on the inside of the outer container 30. electronic components unit. The capacitor unit 1 will be described in detail below.

[0036] The exterior container 30 is composed of two parts, namely, an exterior cup (second part) 60 and an exterior cap (first part) 40 separated up and down. Both the exterior cover 40 and the exterior cup 60 are formed of a plastic material such as LCP (liquid cr...

no. 2 Embodiment approach

[0069] Such as Figure 14 As shown, the exterior container 103 of the capacitor unit 101 is composed of two parts: an exterior cup (first part) 160 and an exterior cover (second part) 140 separated into upper and lower parts. The exterior cup 160 is in the shape of a circular bottomed cup with an open top, and the exterior lid 140 is in the shape of a cylinder having substantially the same diameter as the exterior cup 160 .

[0070] The exterior cup 160 has a protrusion 167 that extends upward from the bottom surface 163 and is inserted into the exterior lid 140 . The lead frame 15 a is pressed against the inner wall side surface 145 of the exterior cover 140 through the protrusion 167 , and is sandwiched between the inner wall side surface 145 and the outer side surface of the protrusion 167 . In addition, when viewed from the surface electrode 19b, the protrusion 167 exists between the closest position 116 of the lead frame 15a and the surface electrode 19b. That is, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com