High-pressure gas circuit connector

A high-pressure gas circuit and connector technology, applied in the direction of couplings, mechanical equipment, etc., can solve the problems of high-pressure gas leakage at the seal, unsuitable gas transmission with high pressure, etc., and achieve good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with above-mentioned accompanying drawing example the present invention is described in further detail:

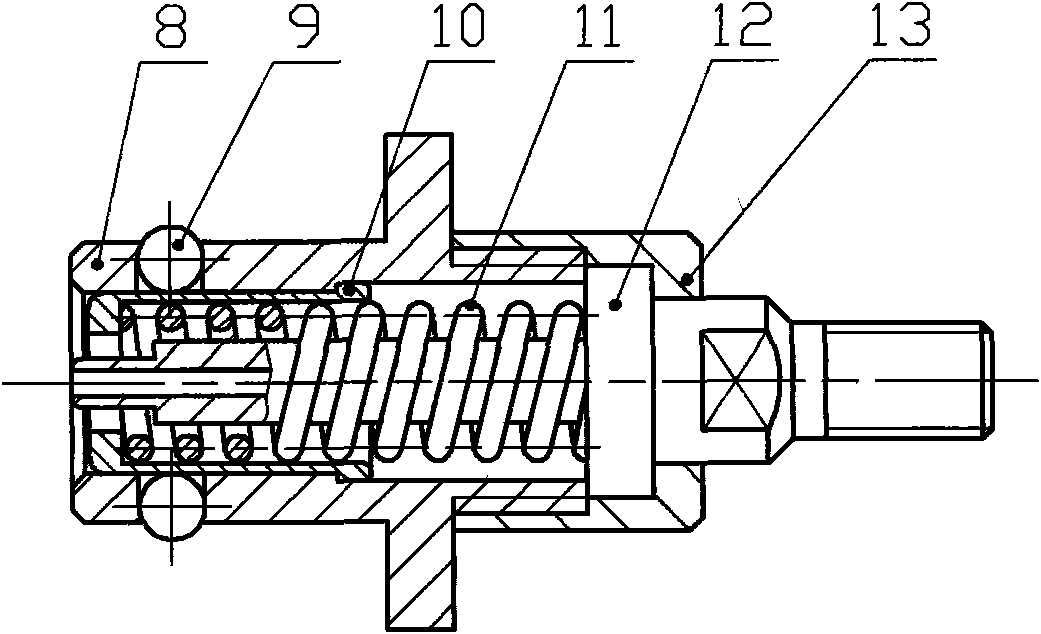

[0020] The high-pressure gas circuit connector of the present invention includes a plug and a socket.

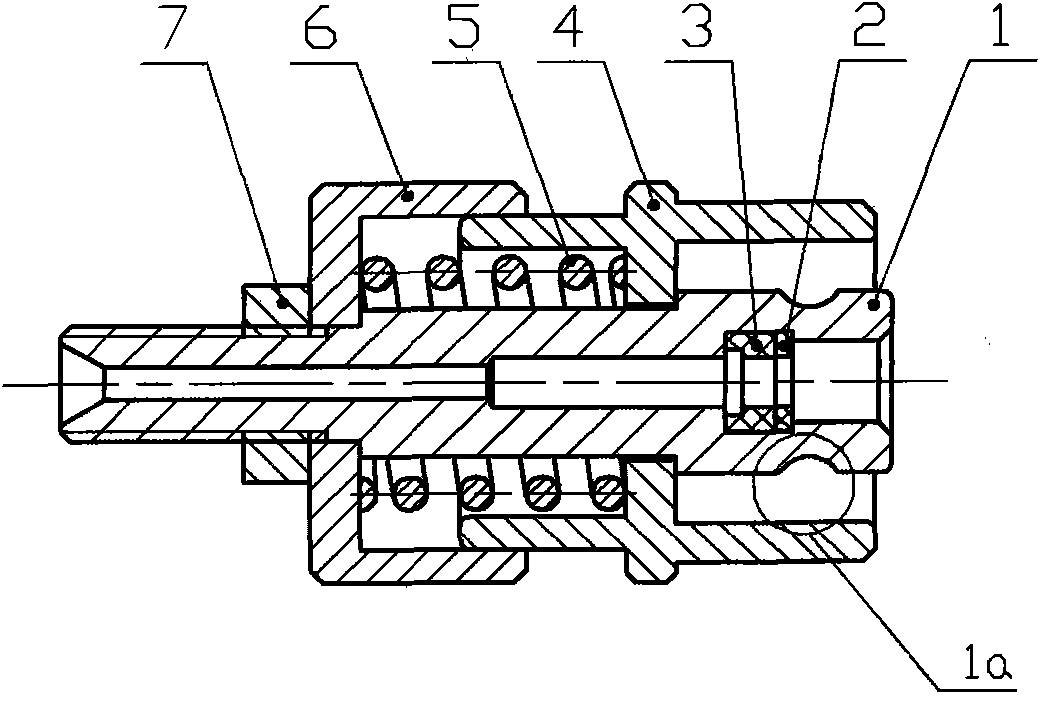

[0021] Among them, the plug includes a plug gas circuit jack 1, a gasket 2, a sealing gasket 3, an unlocking sleeve 4, a locking spring 5, a shell 6 and a nut 7, and the plug gas circuit jack 1 is a shaft part, which is provided with a high-pressure gas passage. Through hole, the tail is a threaded connection interface, which is used to connect the gas pipeline. In order to realize the high-pressure sealing of the mating interface, the sealing gasket 3 and the gasket 2 are arranged in the hole of the air passage socket 1. The sealing ring 3 is made of flexible silicon rubber material, and is designed as a stepped inner hole structure, with For a better sealing function, the gasket 2 is made of flexible polytetrafluoroethylene material, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com