Electrode for electrochemical device and electrochemical device using the same

A technology of electrochemical components and electrodes, which is applied in the field of electrochemical components, can solve the problems of unresolved negative electrodes, heat generation, and unclear relationship between specific surface area, etc., and achieve heat generation reaction suppression, excellent safety, high rate characteristics and low temperature characteristics excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

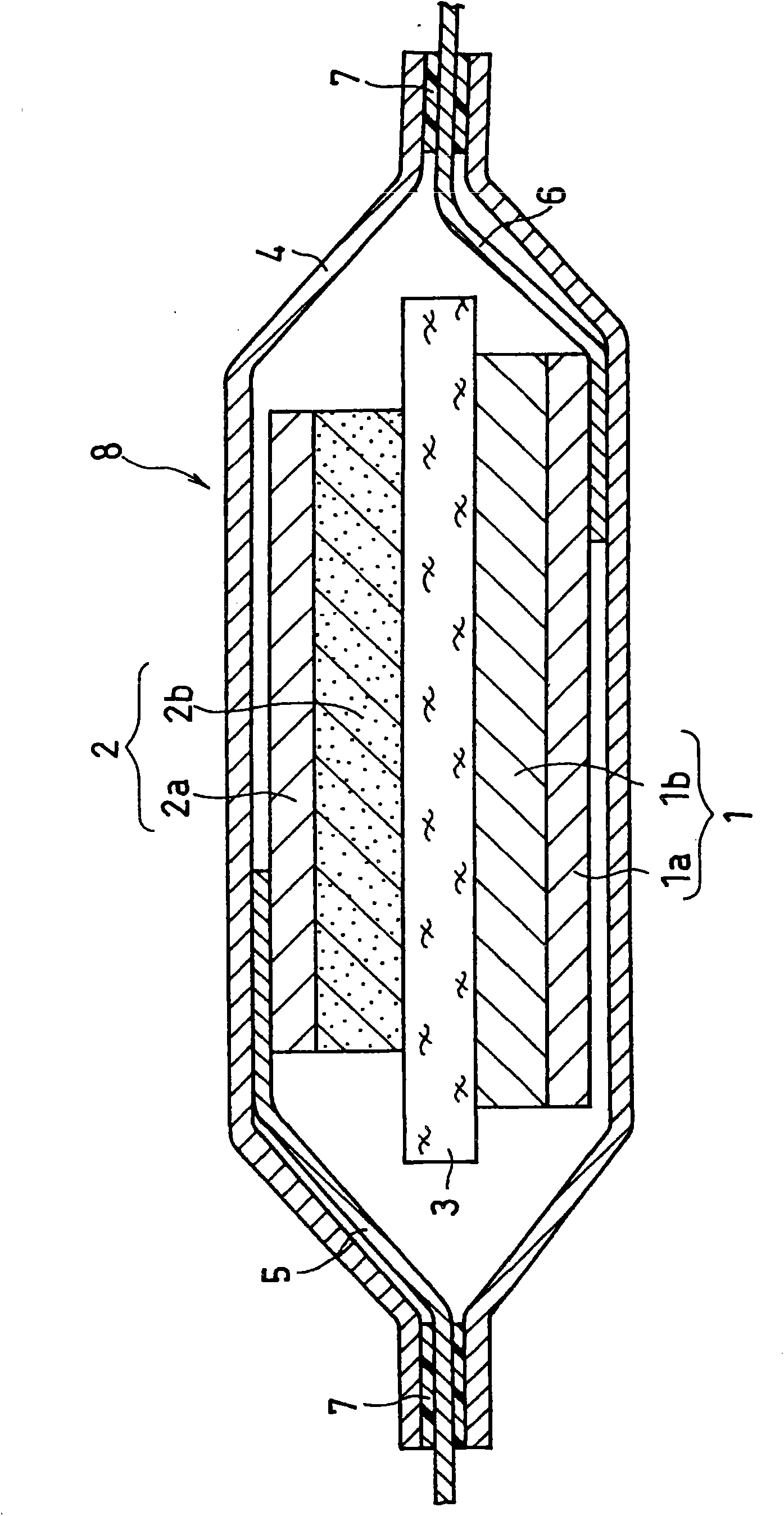

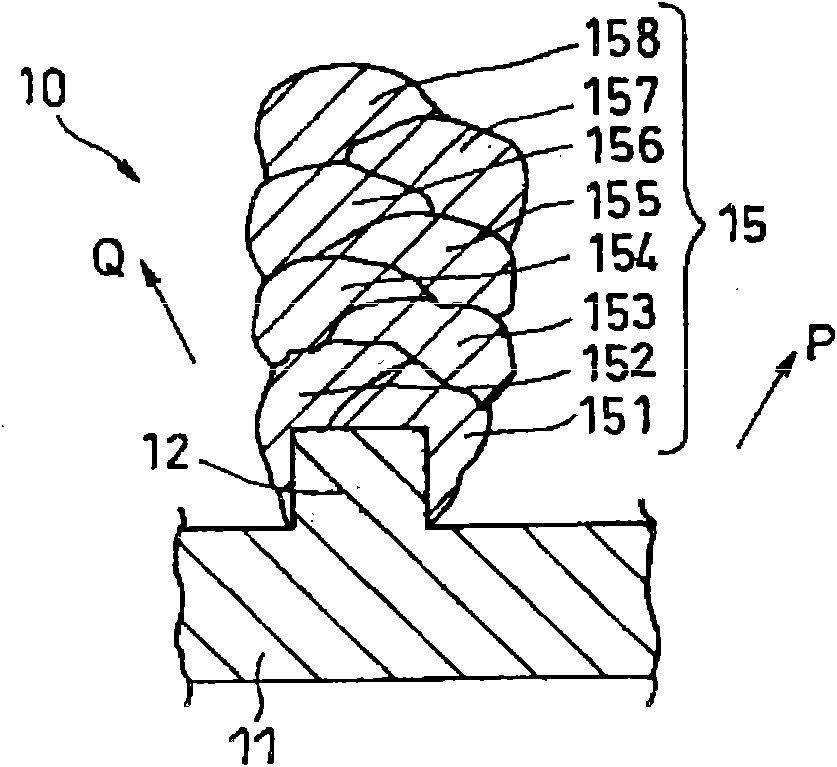

[0104] use figure 2 The negative electrode for a non-aqueous electrolyte secondary battery of this embodiment will be described. figure 2 It is a longitudinal cross-sectional view of main parts of the negative electrode for a nonaqueous electrolyte secondary battery of the present embodiment.

[0105] Such as figure 2 As shown, the negative electrode 10 is composed of a negative electrode current collector 11 having a convex portion 12 on one side and columnar particles 15 formed on the convex portion 12 . The columnar particles are composed of a stack of eight particle layers 151 , 152 , 153 , 154 , 155 , 156 , 157 , and 158 .

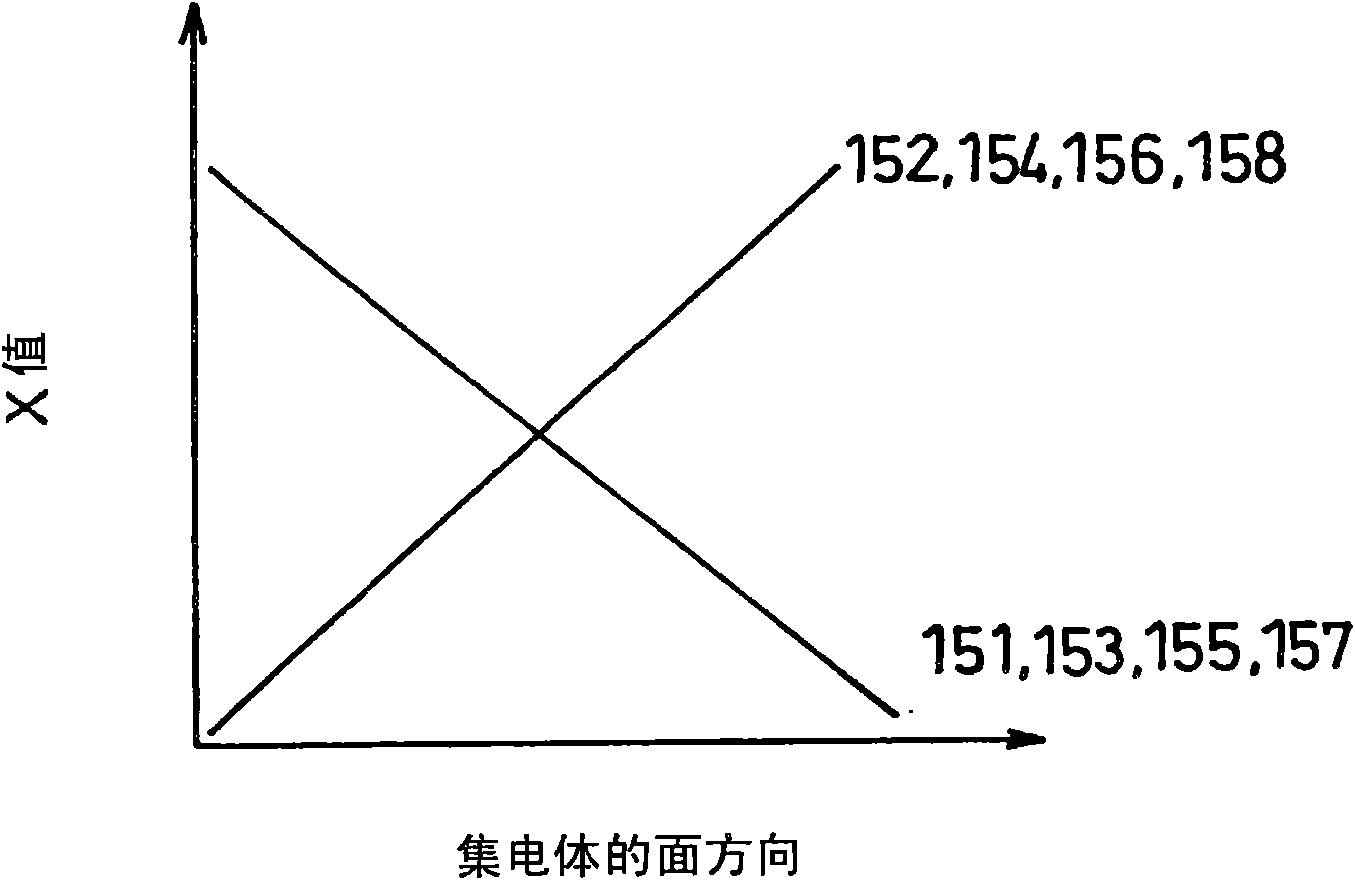

[0106] Counting from the bottom of the columnar particles 15, the particle layers 151, 153, 155, and 157 of the odd-numbered layers (1st, 3rd, 5th, and 7th layers) are inclined toward the first direction P with respect to the normal direction of the current collector. Counting from the bottom of the columnar particles 15, the particle layers 152...

Embodiment approach 2

[0137] use Figure 14 The negative electrode for a non-aqueous electrolyte secondary battery of this embodiment will be described. Figure 14 It is a longitudinal sectional view of main parts of the negative electrode of the present embodiment.

[0138] Such as Figure 14 As shown, the negative electrode 100 has a negative electrode current collector 111 and a negative electrode active material layer 115 covering the surface of the negative electrode current collector 111 . The negative electrode active material is preferably SiOx (02 / g~8m 2 / g. More preferably, the BET specific surface area of the negative electrode active material layer 115 is 5.5m 2 / g~7.5m 2 / g. In addition, the negative electrode active material layer 115 in the charged state preferably has a BET specific surface area of 0.1 m 2 / g~1.7m 2 / g.

[0139] The negative electrode 100 can be obtained, for example, by forming a negative electrode active material layer with a smooth surface on the ne...

Embodiment approach 3

[0145] use Figure 15 The negative electrode for a non-aqueous electrolyte secondary battery of this embodiment will be described. Figure 15 It is a longitudinal sectional view of main parts of the negative electrode of the present embodiment.

[0146] Such as Figure 15 As shown, the negative electrode 200 has columnar particles 215 formed obliquely with respect to the normal direction of the current collector 211 on the convex portion 212 on the surface of the current collector 211 . The columnar particles 215 have a plurality of discrete protrusions 216 on the surface on the side forming an obtuse angle with the surface direction of the current collector 211 . A plurality of protrusions 216 are dispersed on the surface of the current collector without overlapping each other. More specifically, the plurality of protrusions 216 are discretely formed at an angle θ that forms an obtuse angle with the surface direction (A-A direction) of the current collector 11 in the growt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com