Thermoelectric conversion element, thermoelectric conversion module, and process for producing thermoelectric conversion element

A technology of thermoelectric conversion and manufacturing method, which is applied in the manufacture/processing of thermoelectric devices, junction lead-out materials of thermoelectric devices, thermoelectric devices using only Peltier or Seebeck effect, etc. Occupancy rate, simplification of manufacturing processes, and good economic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

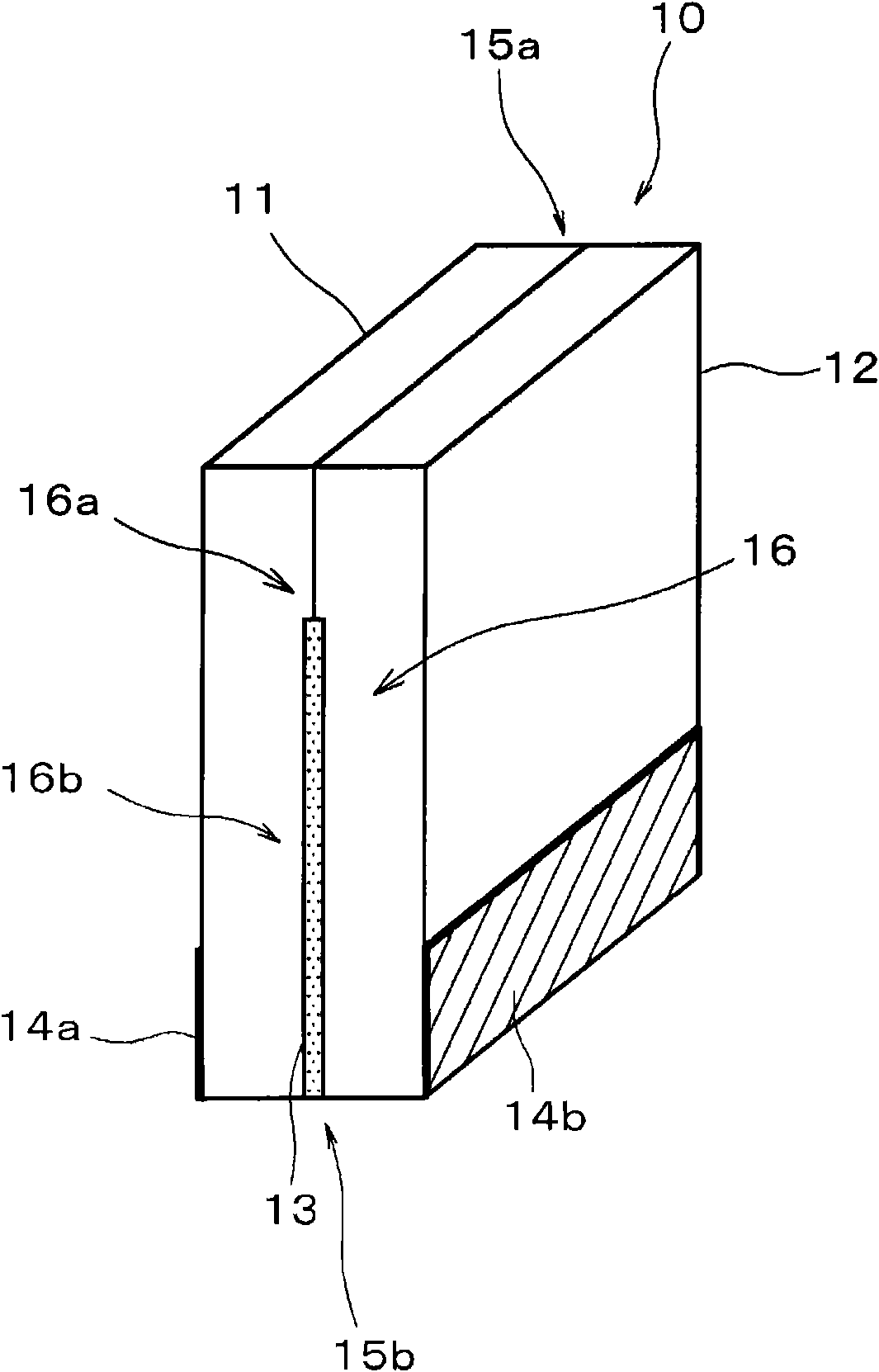

[0062] figure 1 It is a figure which shows the thermoelectric conversion element 10 which is one embodiment (Embodiment 1) of this invention. Such as figure 1 As shown, the thermoelectric conversion element 10 of Embodiment 1 includes a p-type thermoelectric conversion material (hereinafter referred to as "p-type oxide thermoelectric conversion material") 11 formed of a material mainly composed of oxide and a p-type thermoelectric conversion material composed of oxide as a main component. An n-type thermoelectric conversion material (hereinafter referred to as “n-type oxide thermoelectric conversion material”) 12 formed of a material as a main component.

[0063] In addition, in the thermoelectric conversion element 10 according to the first embodiment, in the part region 16a of the junction surface 16 of the p-type oxide thermoelectric conversion material 11 and the n-type oxide thermoelectric conversion material 12, the p-type oxide thermoelectric conversion material 11 a...

Embodiment approach 2

[0095] figure 2 It is a diagram showing a schematic configuration of a thermoelectric conversion module according to Embodiment 2 of the present invention.

[0096] The thermoelectric conversion module 20 of Embodiment 2 has a structure in which a plurality of thermoelectric conversion elements 10 having one p-type oxide thermoelectric conversion material 11 and one n-type oxide thermoelectric conversion material 12 are bonded, and A first electrode 14a and a second electrode 14b are disposed on the lower portion (low temperature side joint portion) 15b.

[0097] Also, although figure 2 shows a structure including three thermoelectric conversion elements 10 composed of a pair of p-type oxide thermoelectric conversion materials 11 and n-type oxide thermoelectric conversion materials 12, but the number of thermoelectric conversion elements 10 constituting the thermoelectric conversion module 20 Not particularly limited.

[0098] In addition, in the thermoelectric conversion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com