Device for introducing metal bars into a metal bath

A metal liquid tank and metal ingot technology, which is applied in the fields of metal material coating technology, lighting and heating equipment, preheating costs, etc. slow thermal process etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

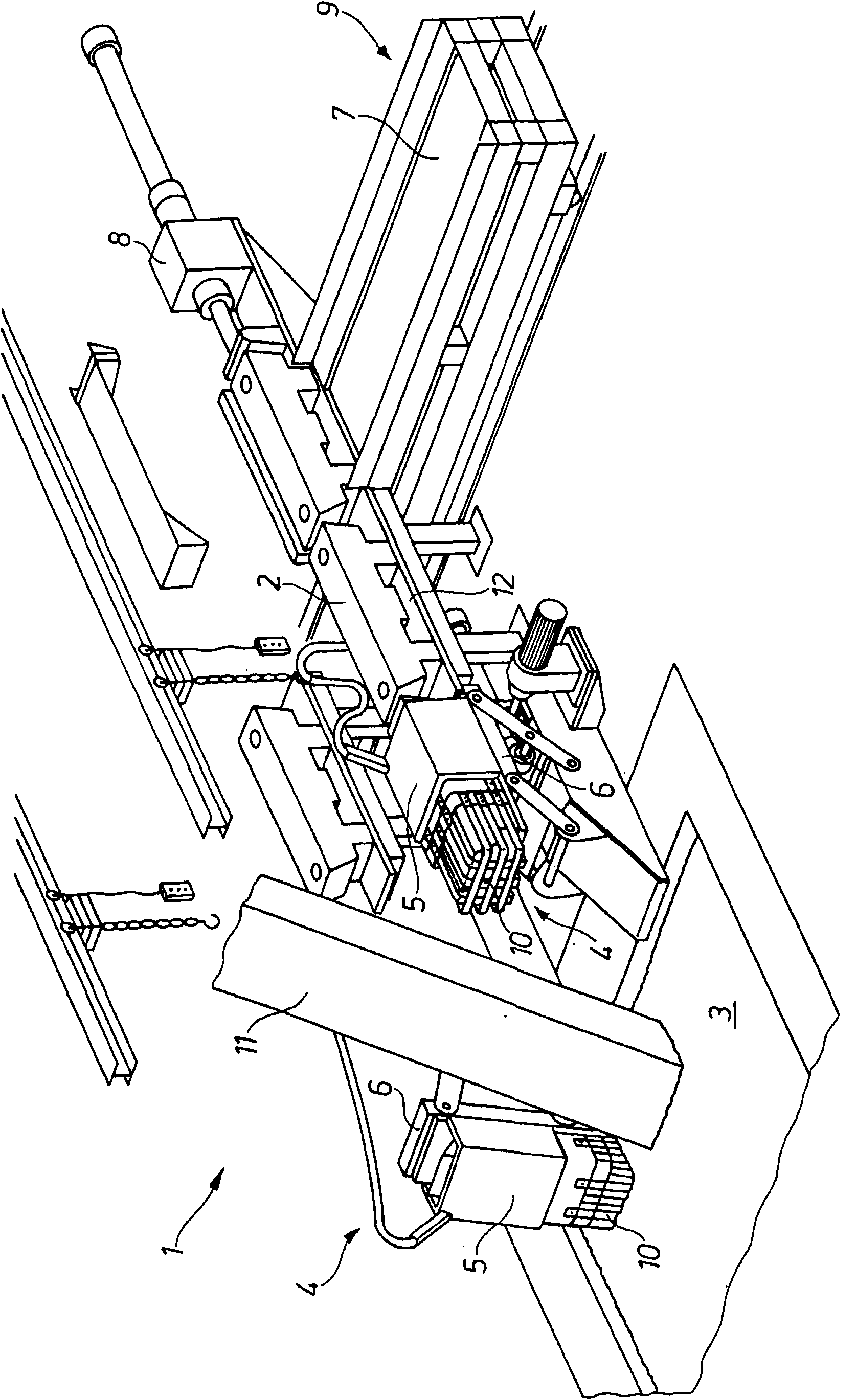

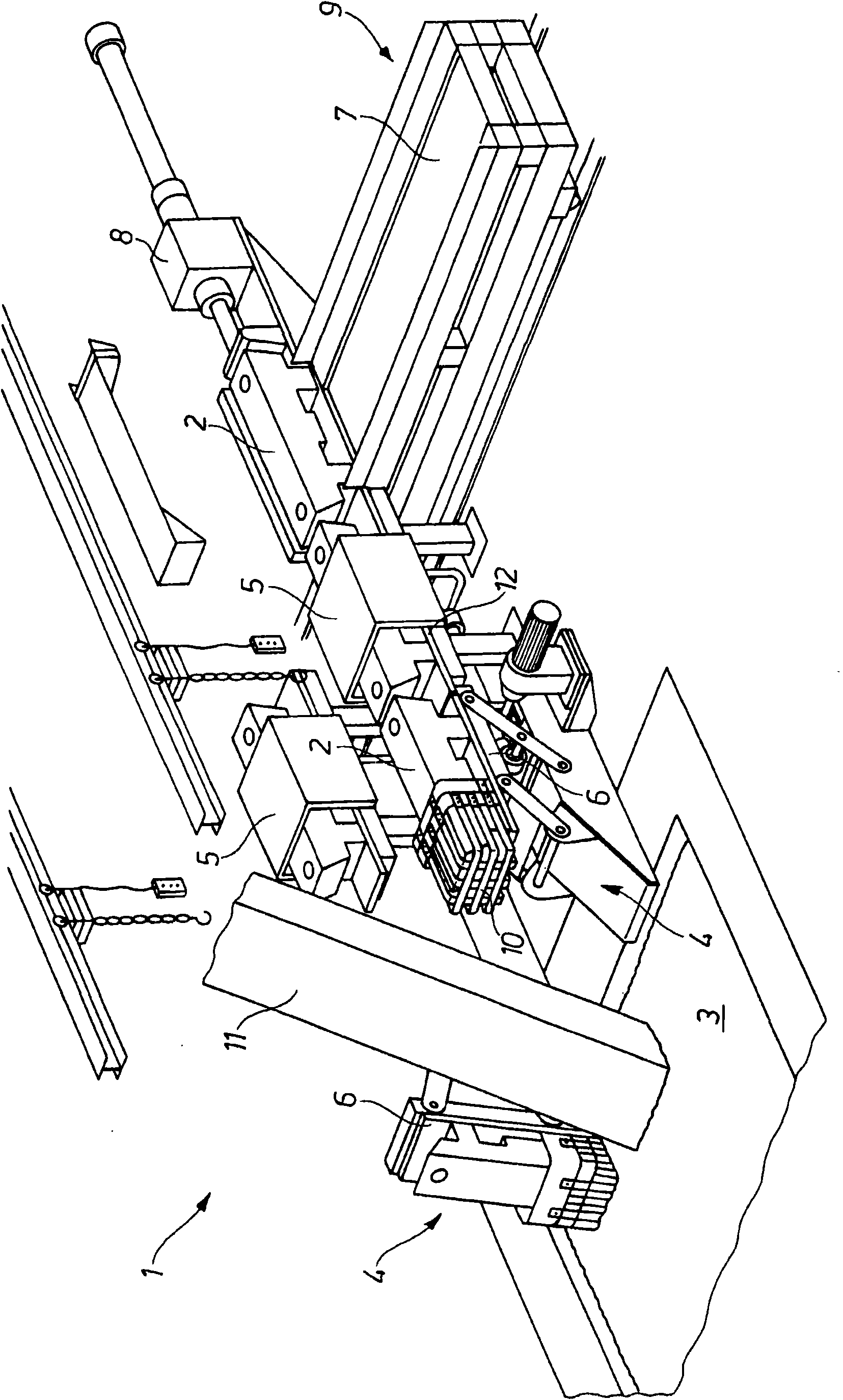

[0021] exist figure 1 A device 1 for feeding zinc ingot billets 2 into a molten metal tank 3 is shown in . In a known manner, furnace tuyeres 11 protrude from a molten metal bath 3 in which a metal strip (not shown) to be coated passes. The feeding of the ingot 2 into the molten metal tank 3 is accomplished by means of the conveying mechanism 4 shown. The holding device 6 is a component of the conveying device 4 and holds the ingot 2 to be introduced into the molten metal bath 3 in such a way that the ingot can be immersed in the bath 3 to the desired extent and thus melted.

[0022] The heating unit 5 is an essential component of the device 1 and has self-sufficiently operating heating elements which can operate independently of other system components which cooperate with the device 1 . The heating element is mainly an independent energy supply mechanism, which is not related to other equipment components. In particular, no heat from other furnaces is used to heat the ing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com