Pneumatic component

A component and pneumatic technology, applied in the direction of engine components, variable displacement pump components, pump components, etc., can solve the problems of not being able to apply mass production, small process reliability, etc., achieve high sealing performance, and save the effect of sealing grease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

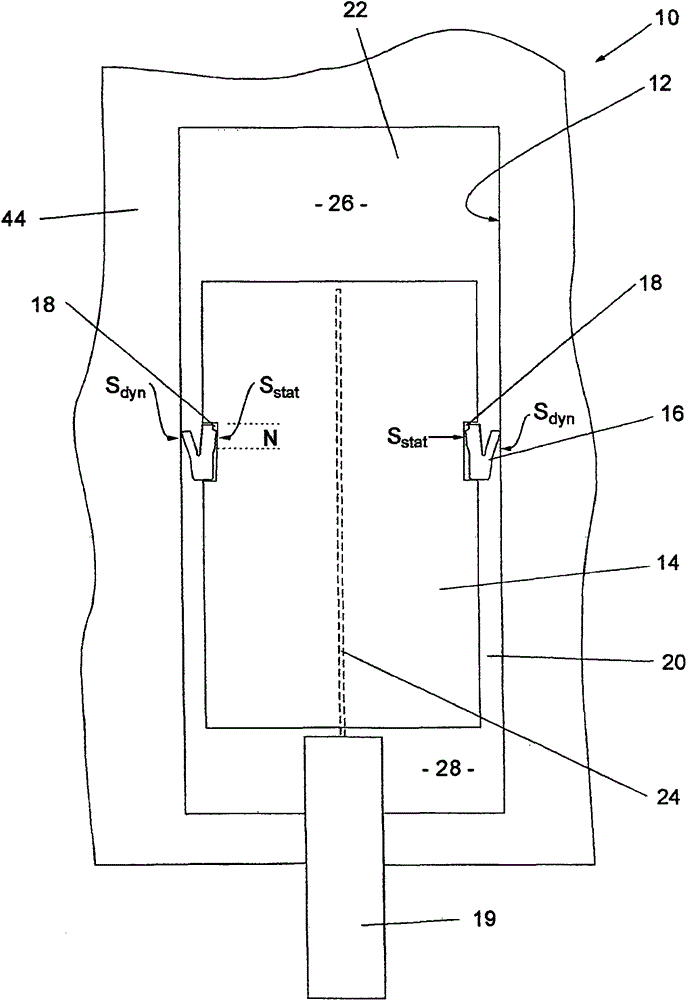

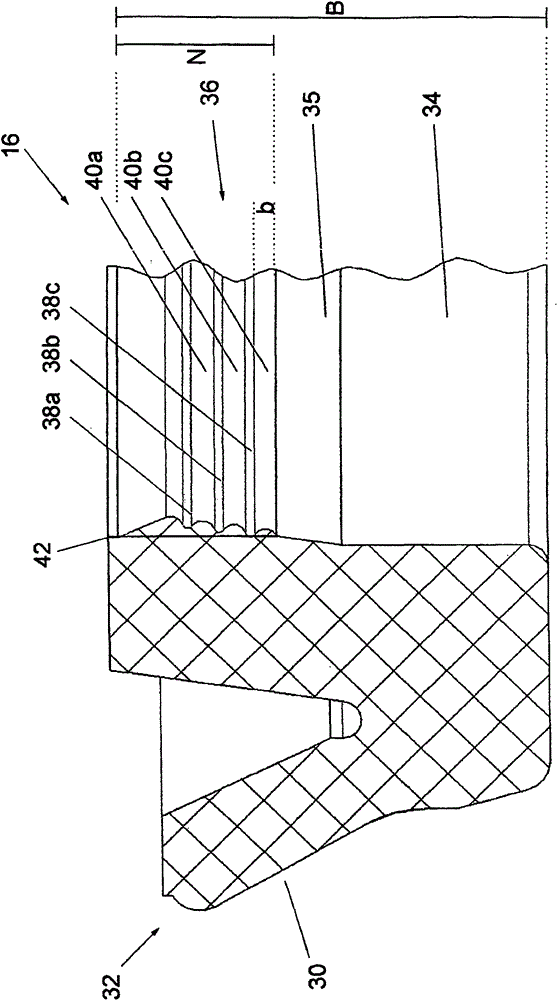

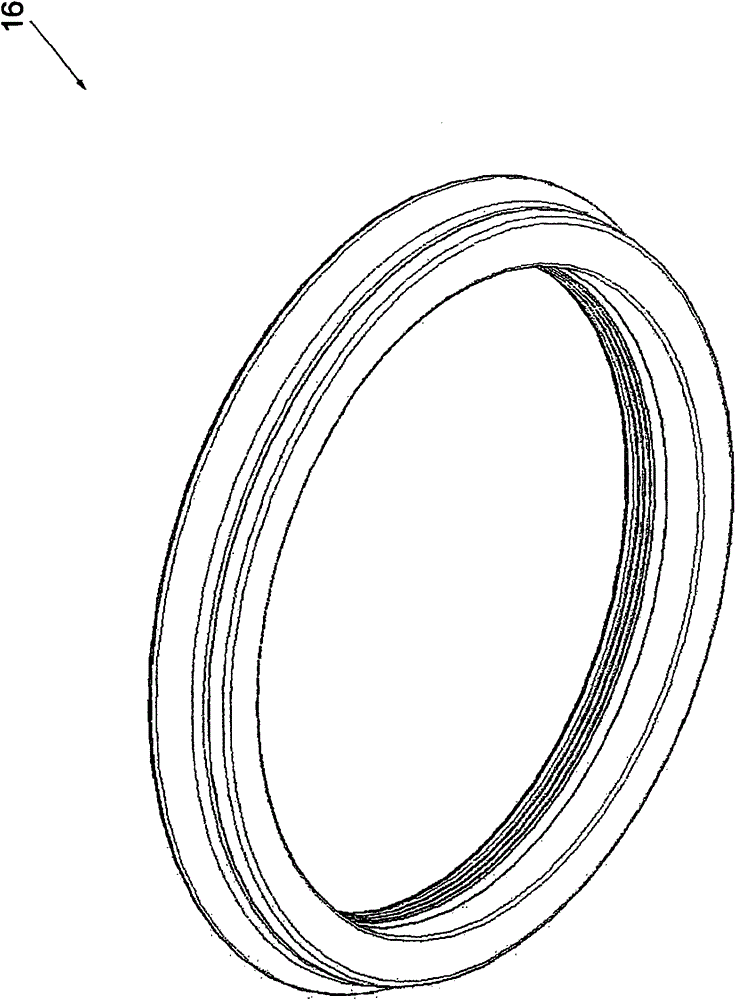

[0020] figure 1 A pneumatic component is shown in the form of a compressor 10 comprising a cylinder 12 , a piston 14 operating within the cylinder 12 , and a grooved ring 16 . The grooved ring 16 is fixed in a groove 18 surrounding the piston 14 . Piston 14 can reciprocate on connecting rod 19 . When the piston 14 is pushed into the cylinder 12, the grooved ring 16 seals the gap 20 between the cylinder 12 and the piston 14, so that the air 22 inside the cylinder 12 is compressed to the air pressure p. Compressed air exits the cylinder through a non-return valve, not shown, and as the piston 14 moves out of the cylinder 12, the air can flow through the grooved ring 16 and through the gap 20 to be compressed in the following stroke.

[0021] The piston 14 is produced from plastic in an injection molding process, which results in the formation of molding surface flashes 24 , which are schematically drawn in dashed lines and extend along the longitudinal axis of the piston 14 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com