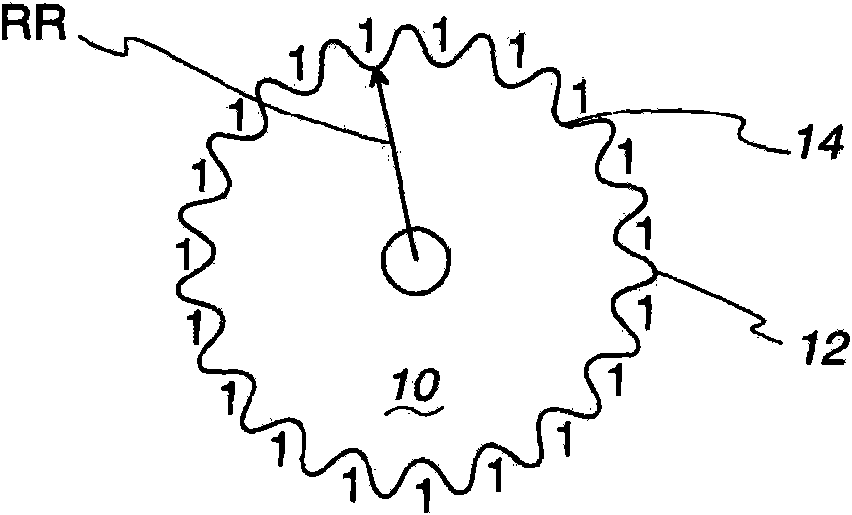

Resonance tension reducing sprocket with combined radial variation and sprocket wrap

A sprocket, wrapping angle technology, applied to components with teeth, belts/chains/gears, hoisting devices, etc., can solve problems such as increased wear and tear of the chain and sprocket system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

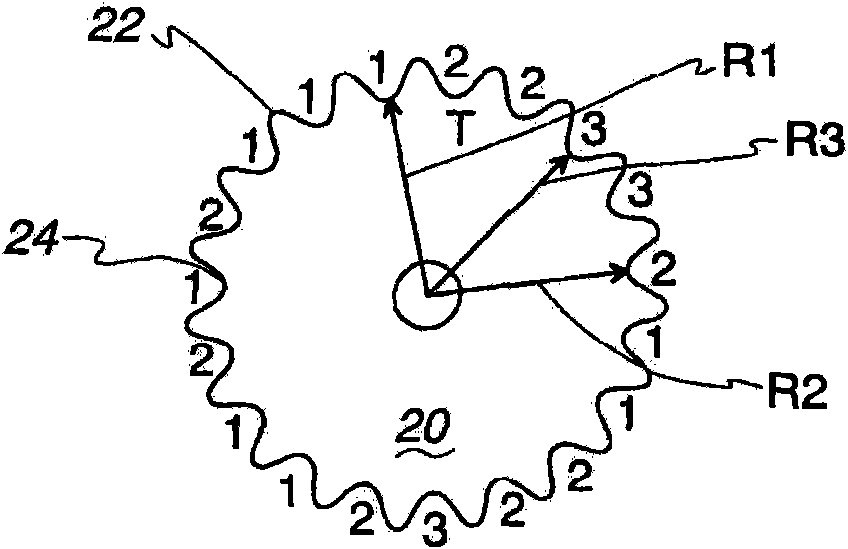

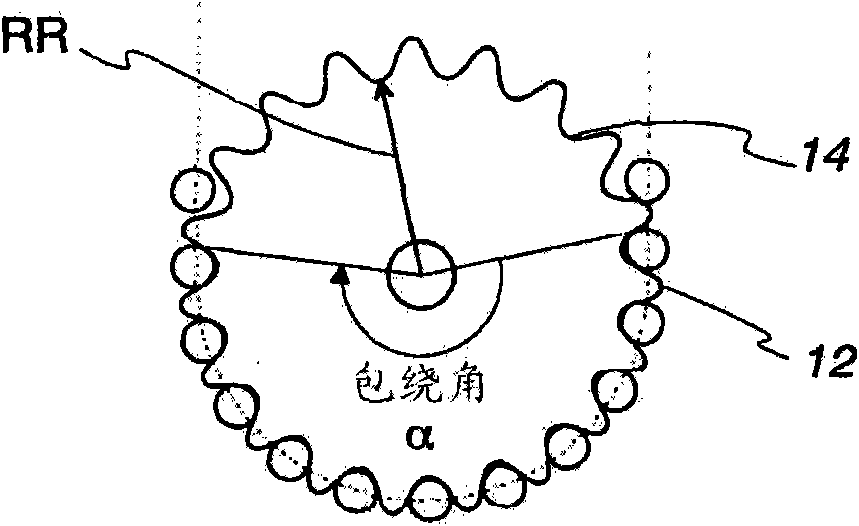

[0041] In the chain and sprocket system described herein, the effectiveness of the chain and sprockets in reducing chain tension is dependent on the radial variation or number of sprocket stages, the amount and angle the chain wraps around the sprockets, and the pitch circle or A combination of repeating sequences of root radii. The most efficient magnitude of the wrap angle is defined by Equation 1 given below:

[0042]

[0043] Among them: N=1, 2, ..., series -1

[0044] And, number of stages = number of sprocket stages caused by tensioning events originating outside the chain and / or sprockets.

[0045] In an important aspect of using the wrap angles described above, a random sprocket can be used in an automotive chain and sprocket system, such as in an engine timing system. The chain and sprockets are connected to an internal combustion engine which runs the chain and sprockets at variable speeds. The sprocket has a repeating sequence of dedendum or pitch radii connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com