Cylinder apparatus

A cylinder device and cylinder technology, which are applied to brake transmission devices, cylinders, fluid pressure actuating devices, etc., can solve the problems of increased sliding resistance of pistons and deteriorated running feeling, and achieve reduction of invalid stroke and increase of sliding resistance. , simple shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

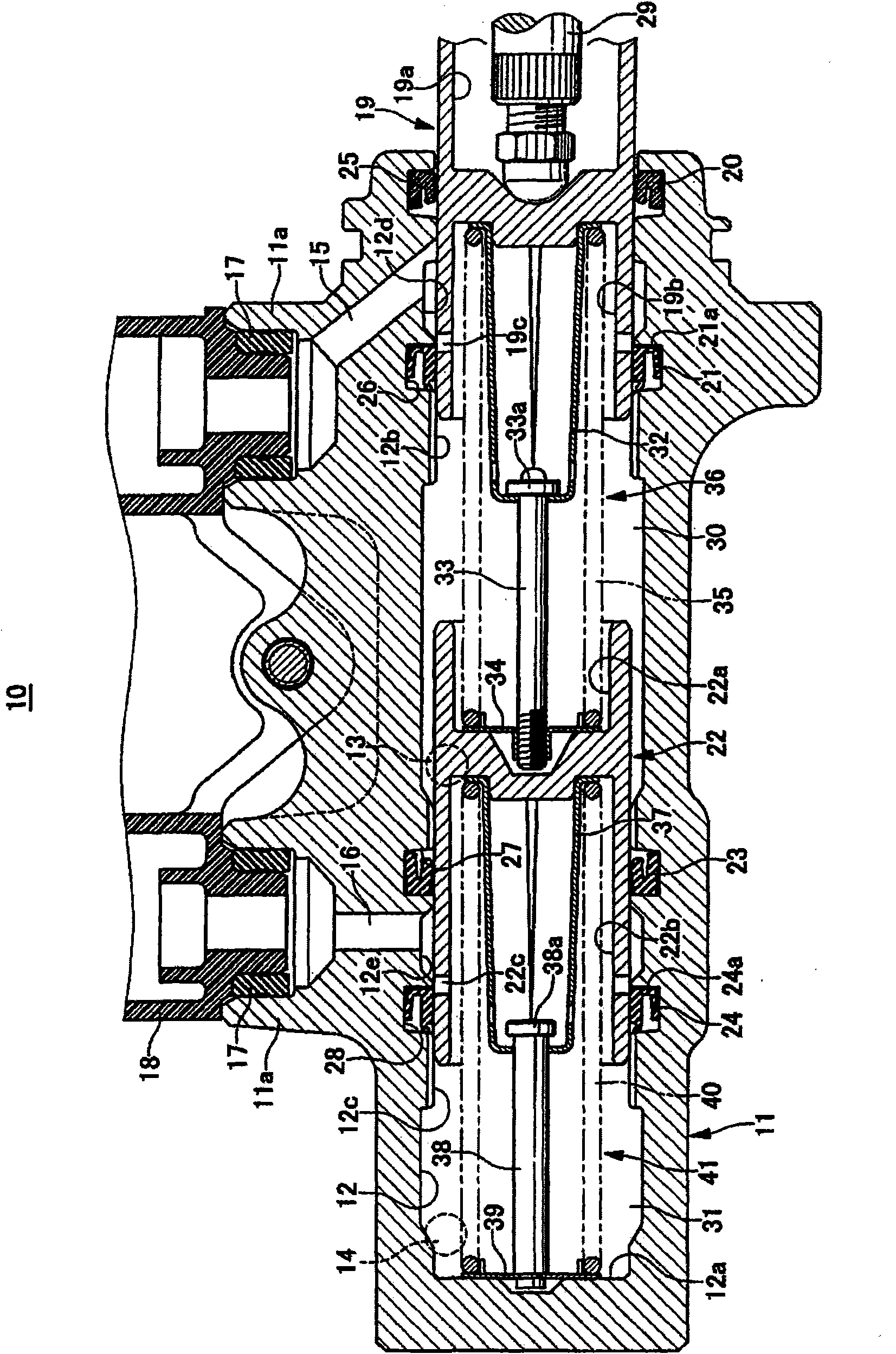

[0050] Figure 1 to Figure 5C An embodiment in which the cylinder device of the present invention is applied to a plunger-type vehicle hydraulic master cylinder is shown.

[0051] First, as image 3As shown, in the hydraulic master cylinder 10 , a bottomed cylinder bore 12 is formed in the cylinder body 11 . The cylinder main body 11 is formed with a first output port 13 opened to a middle portion along the axial direction of the cylinder of the cylinder bore 12 and a second output port 14 opened on the bottom side of the cylinder bore 12 . In addition, a pair of bosses are provided to protrude on the upper portion of the cylinder main body 11 . First and second fluid passage holes 15 and 16 communicating with the cylinder bore 12 are provided in the two bosses 11a and 11a, respectively. The accumulator 18 is connected to the bosses 11a and 11a via grommet seals 17 and 17 .

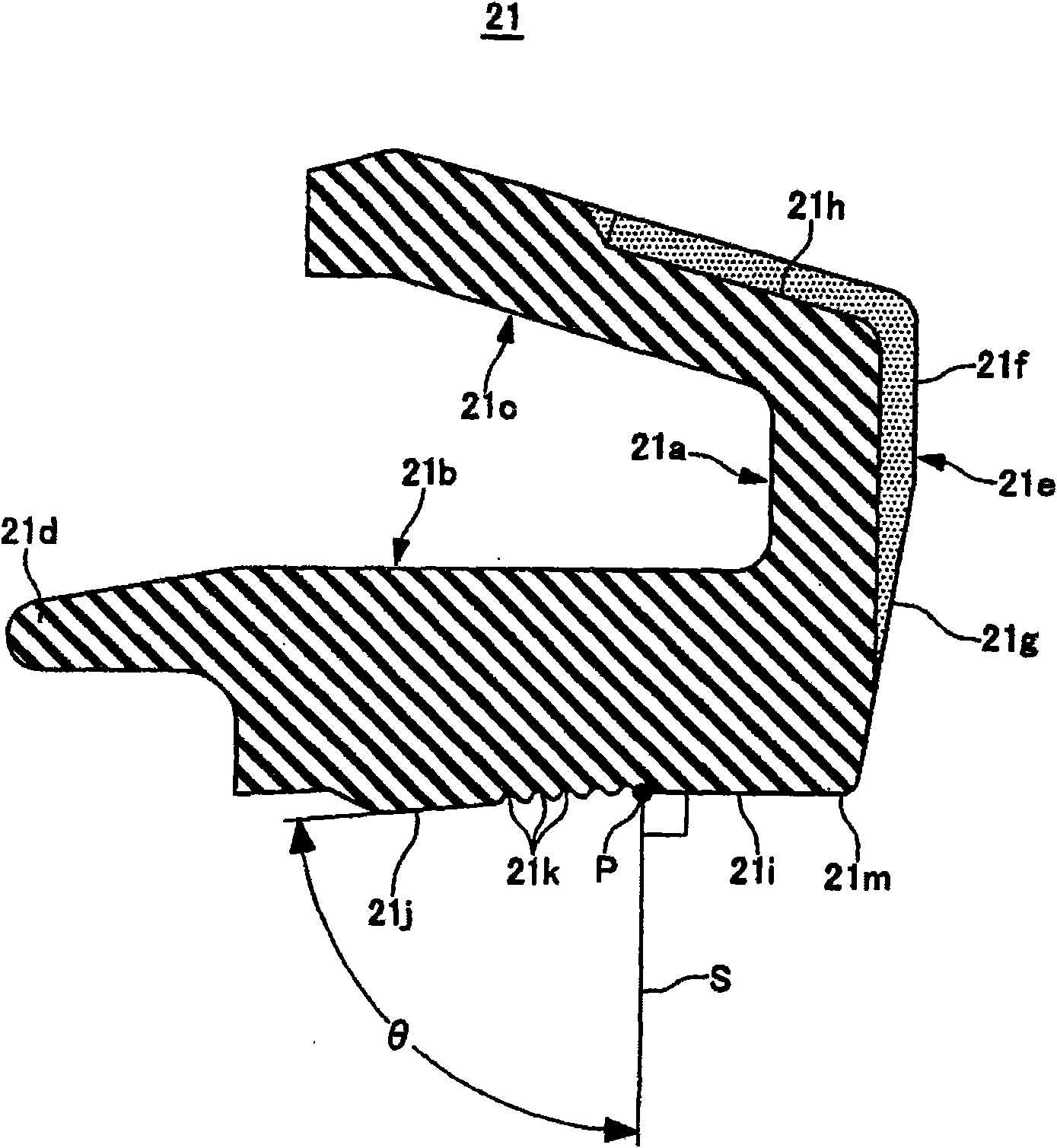

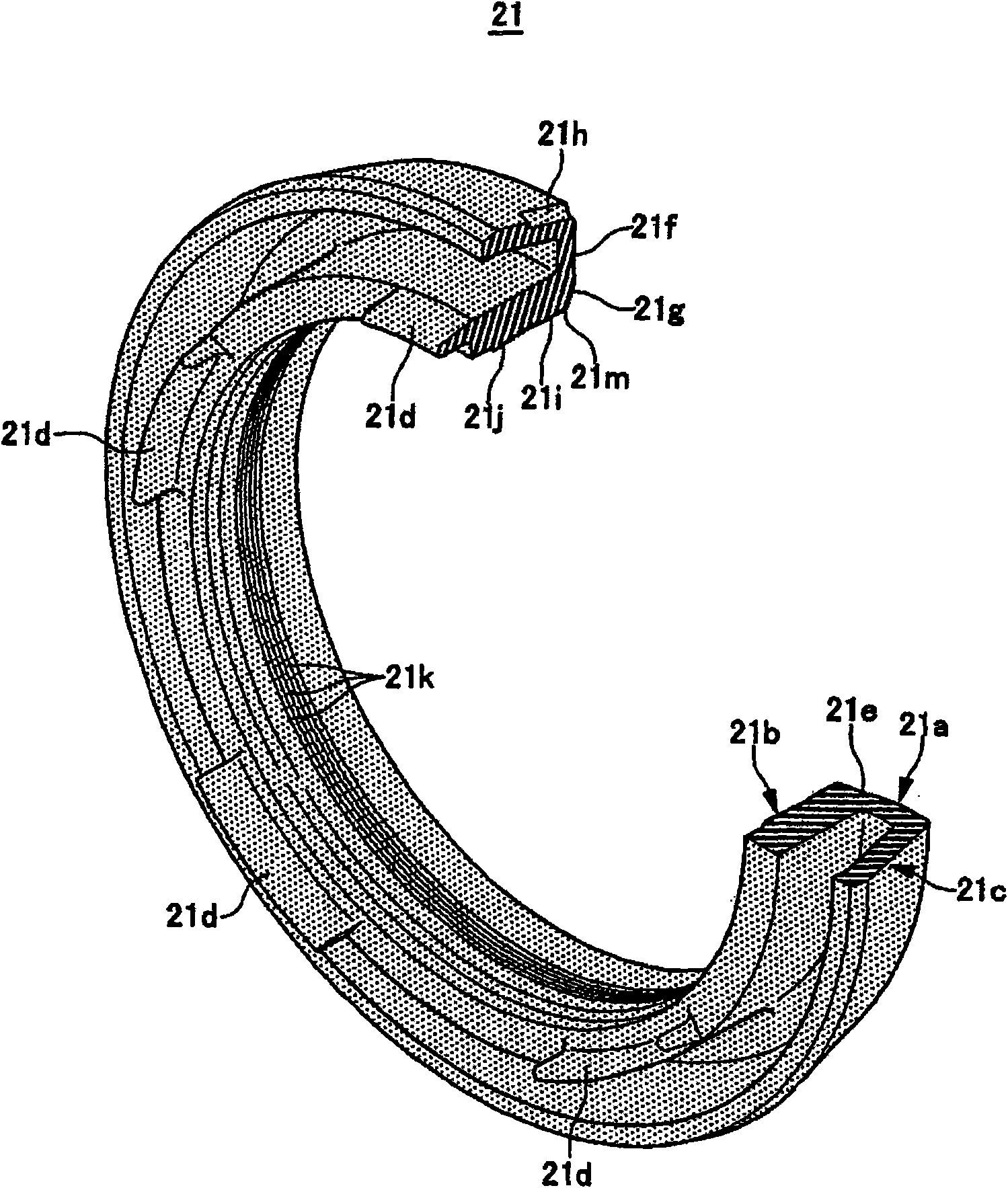

[0052] In the cylinder bore 12, the first plunger 19 (piston) can be slidably inserted via the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com