Frame structure of bearing sealing-ring with high strength

A technology of bearing sealing and skeleton structure, which is applied to the sealing of bearing components, shafts and bearings, and engines, which can solve the problems of reduced contact, deformation of sealing rings, and loosening of sealing rings, and achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

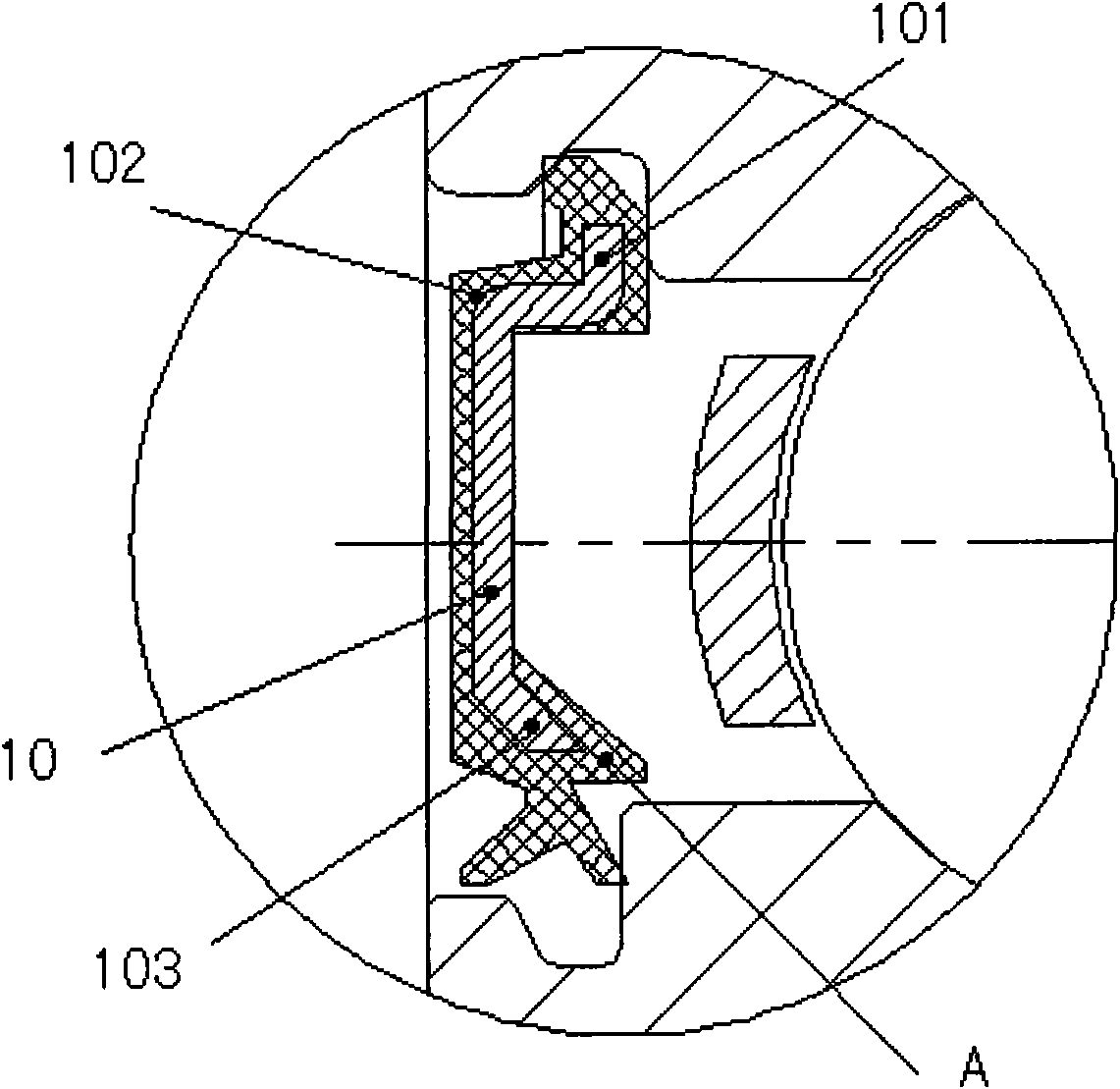

[0010] Depend on figure 2 It can be seen that the present invention includes: a body 10; said body 10 is in a "Z" shape; the upper end of the body 10 extends into the outer lip 101 of the sealing ring, and the lower end of the body 10 extends into the third lip 103 of the inner lip of the sealing ring; Between the upper and lower ends of the body 10 near the upper portion of the body 10 is a corner 102 .

[0011] What the present invention adopts is a shape standing up "Z" character, the structure has three corners ("101", "102", "103"), one end of the skeleton extends into the outer lip of the sealing ring, and the other end extends into the The third lip of the inner lip of the seal. The benefits of doing this are:

[0012] In this way, the skeleton of the sealing ring uses the principle of mechanics to increase the strength of the entire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com