Signal transmitter for a filling level sensor

A technology for signal generators and liquid level sensors, which can be used in buoy liquid level indicators, sliding contact resistors, etc., and can solve the problems of high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

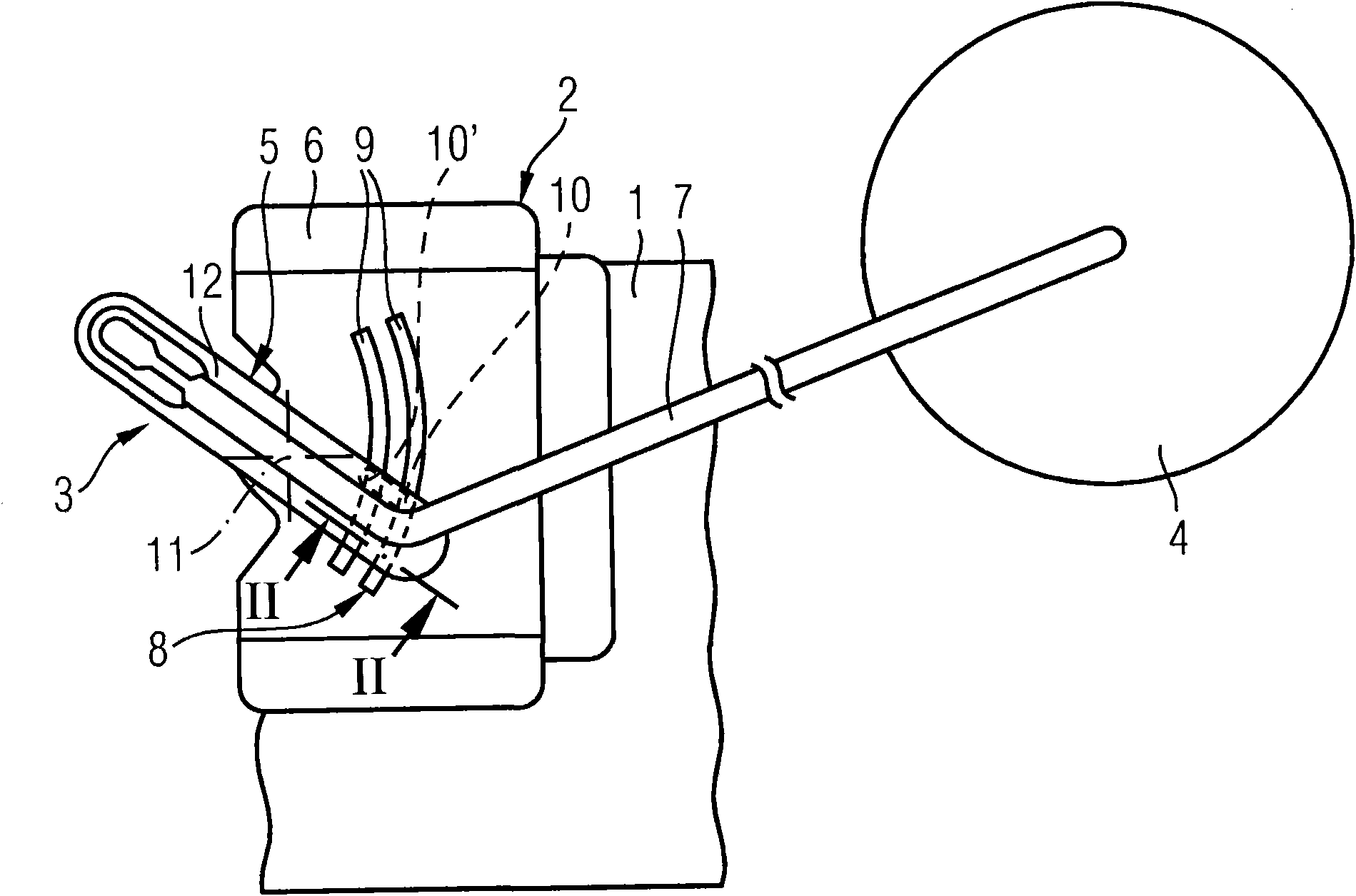

[0016] figure 1 A fill level sensor 2 installed in a vertical wall 1 inside the fuel tank is shown. The level sensor 2 has a float 4 fastened on a lever arm 3 . The float 4 moves with the fuel level (not shown) in the fuel tank and thus deflects the lever arm 3 . The lever arm 3 is pivotably supported on a support 6 with a bow 5 made of plastic and has a lever wire 7 fastened to the bow 5 for supporting the float 4 . The pivoting angle of the lever arm 3 is detected by a signal generator 8 designed as a potentiometer and converted into an electrical signal. The signal generator 8 has two sliding rails 9 , 9 ′ arranged on the support 6 and two sliding contacts 10 , 10 ′ fixed on the bow 5 and electrically connected to each other for bridging the sliding rails 9 ,9'. An electrical signal corresponding to the fuel level is thus present at the carrier 6 and thus at the fixed part of the fill level sensor 2 . The lever arm 3 has a bearing structure in the bearing 6 with a bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com